10 changed files with 189 additions and 94 deletions

Split View

Diff Options

-

+93 -0HP_Pavilion_15_cs0053/docs/2.tex

-

+96 -0HP_Pavilion_15_cs0053/docs/3.tex

-

BINHP_Pavilion_15_cs0053/pics/what_is_important.jpg

-

BINHP_Pavilion_15_cs0053/resources/AOZ2023PI.pdf

-

BINHP_Pavilion_15_cs0053/resources/DS8068A-03.pdf

-

BINHP_Pavilion_15_cs0053/resources/EDS-5934.pdf

-

BINHP_Pavilion_15_cs0053/resources/HP Pavilion 15 series (Quanta R62) FreeLaptop Schematics Download.pdf

-

BINHP_Pavilion_15_cs0053/resources/as393m.pdf

-

BINHP_Pavilion_15_cs0053/resources/isl88739b.pdf

-

+0 -94Sony_PVM_14M4U/docs/.11.tex.swp

+ 93

- 0

HP_Pavilion_15_cs0053/docs/2.tex

View File

| @ -0,0 +1,93 @@ | |||

| \documentclass[11pt]{article} | |||

| %Gummi|065|=) | |||

| \usepackage{graphicx} | |||

| \usepackage{caption} | |||

| \title{\textbf{HP Pavilion 15 Repair}} | |||

| \author{Steak Electronics} | |||

| \date{} | |||

| \begin{document} | |||

| \maketitle | |||

| \section{Overview} | |||

| User spilled tonic water on a laptop, then kept it powered on and continued to use it (this was a mistake. Turning it off, and removing battery / power, letting the liquid dry, is always the first step in a spill). The next morning the laptop would not power on. | |||

| \section{Equipment} | |||

| Laptop is an HP Pavilion 15 CS model. They are fairly new (date codes on micros are from 2018), and retailing around 500-600 dollars as of just before 2019. | |||

| \includegraphics[scale=0.2]{../pics/DSCN1016.JPG} | |||

| \captionof{figure}{HP} | |||

| \section{Disassembly} | |||

| There is no video tutorial on this online, but the steps are: Remove visible screws from the back of the case. Remove rubber feet, and screws beneath them. Pry open case from edges with plastic spudger tool to remove the clips. You must be careful, as the clips and case are fragile. | |||

| \begin{itemize} | |||

| \item Where to start with the spudger, and also showing the screwholes underneath the rubber feet. | |||

| \includegraphics[scale=0.2]{../pics/DSCN1019.JPG} | |||

| \captionof{figure}{Disassembly} | |||

| \item I was able to scratch the case with the plastic spudger. Be careful! | |||

| \includegraphics[scale=0.2]{../pics/DSCN1021.JPG} | |||

| \captionof{figure}{Disassembly} | |||

| \item The case can also crack from pulling it. I didn't pull this hard, but the brittle weak case cracked slightly. | |||

| \includegraphics[scale=0.3]{../pics/DSCN1022.JPG} | |||

| \captionof{figure}{Disassembly} | |||

| \item Finally we are in. | |||

| \includegraphics[scale=0.3]{../pics/DSCN1023.JPG} | |||

| \captionof{figure}{Disassembly} | |||

| \includegraphics[scale=0.3]{../pics/DSCN1024.JPG} | |||

| \captionof{figure}{Disassembly} | |||

| \item Screws are labeled, to help illustrate what size each is: | |||

| \includegraphics[scale=0.2]{../pics/DSCN1026.JPG} | |||

| \captionof{figure}{Disassembly} | |||

| \end{itemize} | |||

| \section{Diagnosis and Repair Log} | |||

| Now we will try to find out what is wrong. | |||

| \begin{itemize} | |||

| \item Right away I can see some visible marring from a likely shorted component. This is where a lot of the soda residue is. | |||

| \includegraphics[scale=0.4]{../pics/DSCN1029.JPG} | |||

| \captionof{figure}{Repair} | |||

| \item You can see a layer of cellophane that is in place to protect against spills. Amazing how millions of man hours can go into designing computers, yet a single glass of liquid can destroy one. Something is wrong, here. Crazy. | |||

| \includegraphics[scale=0.2]{../pics/DSCN1034.JPG} | |||

| \captionof{figure}{Repair} | |||

| \item This switcher, the BACAAB (?) chip is the one that has the failed components. I need a replacement but can't find a data sheet on it. I tried probing at some of the pins to see what was going on, and if I could understand a bit more about this, but due to me probing too close to the pins, (and a few factors, primarily the small package, but no leads, and also the fact I should've used the pads NEAR but not ON the package, I shorted something, and a spark resulted. While I saw a 2.4V signal on a pin, after the short, I was unable to find anything. The battery being removed and replaced did not bring it back. | |||

| \includegraphics[scale=0.3]{../pics/DSCN1036.JPG} | |||

| \captionof{figure}{Repair} | |||

| \item At this point, this chip, which I am unsure of what it is, appears to have a short and is overheating / shorting. I will need to get a motherboard donor at this point, to further repair the mistakes. As these are new boards, motherboards are not yet cheap enough to make this viable, so I will wait and try again at a later date. | |||

| \includegraphics[scale=0.3]{../pics/DSCN1037.JPG} | |||

| \captionof{figure}{Repair} | |||

| \item During my troubleshooting, I did find an open resistor, and a capacitor that has visible charring on its solder joint. I'll need to replace these as well. I should've replaced this at first, but without a schematic, I don't know what value the cap should be. The resistor is labeled as 1R0, but reads open. There may also be one other cap that has failed. However, some other components appear OK. | |||

| \includegraphics[scale=0.3]{../pics/DSCN1039.JPG} | |||

| \captionof{figure}{Site of failed components from soda water spill.} | |||

| \end{itemize} | |||

| \section{Day Two} | |||

| I've received another motherboard in the mail. Unfortunately, I can NOT get the schematic for this motherboard, but I have an earlier HP version available. Maybe this is why people such as L. Rossman are successful - they focus on Apple, which has available schematic and layout... I have no layout either. | |||

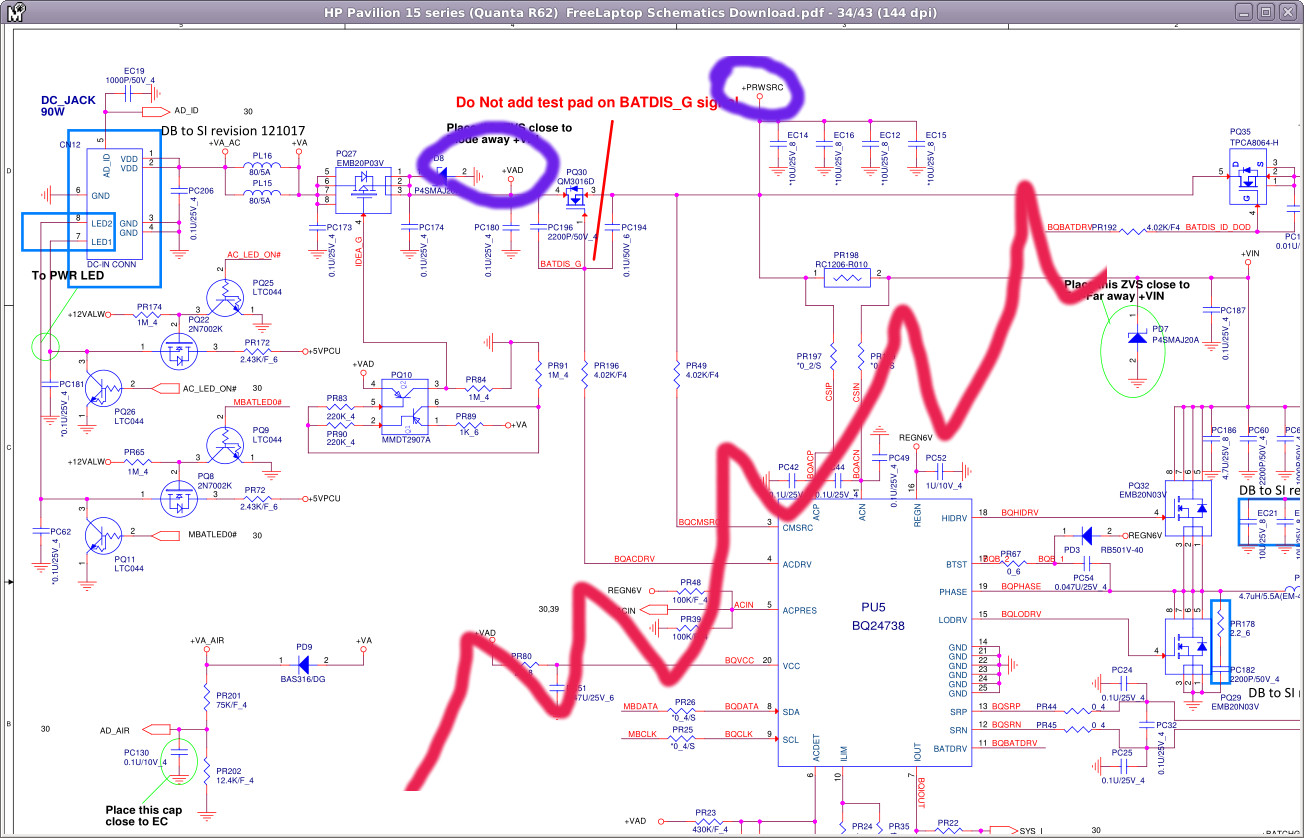

| Looking at this similar schematic, it's important to focus on what matters. checking power rails, I know I need to start at the beginning. Also, when looking at other schematics outside of the power rails you can see what inputs into them and what is relevant. | |||

| \includegraphics[scale=0.3]{../pics/what_is_important.jpg} | |||

| \captionof{figure}{I'm worried about the AC adapter input. All the battery circuitry can be ignored to start, as there is no battery.} | |||

| \end{document} | |||

+ 96

- 0

HP_Pavilion_15_cs0053/docs/3.tex

View File

| @ -0,0 +1,96 @@ | |||

| \documentclass[11pt]{article} | |||

| %Gummi|065|=) | |||

| \usepackage{graphicx} | |||

| \usepackage{caption} | |||

| \title{\textbf{HP Pavilion 15 Repair}} | |||

| \author{Steak Electronics} | |||

| \date{} | |||

| \begin{document} | |||

| \maketitle | |||

| \section{Overview} | |||

| User spilled tonic water on a laptop, then kept it powered on and continued to use it (this was a mistake. Turning it off, and removing battery / power, letting the liquid dry, is always the first step in a spill). The next morning the laptop would not power on. | |||

| \section{Equipment} | |||

| Laptop is an HP Pavilion 15 CS model. They are fairly new (date codes on micros are from 2018), and retailing around 500-600 dollars as of just before 2019. | |||

| \includegraphics[scale=0.2]{../pics/DSCN1016.JPG} | |||

| \captionof{figure}{HP} | |||

| \section{Disassembly} | |||

| There is no video tutorial on this online, but the steps are: Remove visible screws from the back of the case. Remove rubber feet, and screws beneath them. Pry open case from edges with plastic spudger tool to remove the clips. You must be careful, as the clips and case are fragile. | |||

| \begin{itemize} | |||

| \item Where to start with the spudger, and also showing the screwholes underneath the rubber feet. | |||

| \includegraphics[scale=0.2]{../pics/DSCN1019.JPG} | |||

| \captionof{figure}{Disassembly} | |||

| \item I was able to scratch the case with the plastic spudger. Be careful! | |||

| \includegraphics[scale=0.2]{../pics/DSCN1021.JPG} | |||

| \captionof{figure}{Disassembly} | |||

| \item The case can also crack from pulling it. I didn't pull this hard, but the brittle weak case cracked slightly. | |||

| \includegraphics[scale=0.3]{../pics/DSCN1022.JPG} | |||

| \captionof{figure}{Disassembly} | |||

| \item Finally we are in. | |||

| \includegraphics[scale=0.3]{../pics/DSCN1023.JPG} | |||

| \captionof{figure}{Disassembly} | |||

| \includegraphics[scale=0.3]{../pics/DSCN1024.JPG} | |||

| \captionof{figure}{Disassembly} | |||

| \item Screws are labeled, to help illustrate what size each is: | |||

| \includegraphics[scale=0.2]{../pics/DSCN1026.JPG} | |||

| \captionof{figure}{Disassembly} | |||

| \end{itemize} | |||

| \section{Diagnosis and Repair Log} | |||

| Now we will try to find out what is wrong. | |||

| \begin{itemize} | |||

| \item Right away I can see some visible marring from a likely shorted component. This is where a lot of the soda residue is. | |||

| \includegraphics[scale=0.4]{../pics/DSCN1029.JPG} | |||

| \captionof{figure}{Repair} | |||

| \item You can see a layer of cellophane that is in place to protect against spills. Amazing how millions of man hours can go into designing computers, yet a single glass of liquid can destroy one. Something is wrong, here. Crazy. | |||

| \includegraphics[scale=0.2]{../pics/DSCN1034.JPG} | |||

| \captionof{figure}{Repair} | |||

| \item This switcher, the BACAAB (?) chip is the one that has the failed components. I need a replacement but can't find a data sheet on it. I tried probing at some of the pins to see what was going on, and if I could understand a bit more about this, but due to me probing too close to the pins, (and a few factors, primarily the small package, but no leads, and also the fact I should've used the pads NEAR but not ON the package, I shorted something, and a spark resulted. While I saw a 2.4V signal on a pin, after the short, I was unable to find anything. The battery being removed and replaced did not bring it back. | |||

| \includegraphics[scale=0.3]{../pics/DSCN1036.JPG} | |||

| \captionof{figure}{Repair} | |||

| \item At this point, this chip, which I am unsure of what it is, appears to have a short and is overheating / shorting. I will need to get a motherboard donor at this point, to further repair the mistakes. As these are new boards, motherboards are not yet cheap enough to make this viable, so I will wait and try again at a later date. | |||

| \includegraphics[scale=0.3]{../pics/DSCN1037.JPG} | |||

| \captionof{figure}{Repair} | |||

| \item During my troubleshooting, I did find an open resistor, and a capacitor that has visible charring on its solder joint. I'll need to replace these as well. I should've replaced this at first, but without a schematic, I don't know what value the cap should be. The resistor is labeled as 1R0, but reads open. There may also be one other cap that has failed. However, some other components appear OK. | |||

| \includegraphics[scale=0.3]{../pics/DSCN1039.JPG} | |||

| \captionof{figure}{Site of failed components from soda water spill.} | |||

| \end{itemize} | |||

| \section{Day Two} | |||

| I've received another motherboard in the mail. Unfortunately, I can NOT get the schematic for this motherboard, but I have an earlier HP version available. Maybe this is why people such as L. Rossman are successful - they focus on Apple, which has available schematic and layout... I have no layout either. | |||

| Looking at this similar schematic, it's important to focus on what matters. checking power rails, I know I need to start at the beginning. Also, when looking at other schematics outside of the power rails you can see what inputs into them and what is relevant. | |||

| \includegraphics[scale=0.3]{../pics/what_is_important.jpg} | |||

| \captionof{figure}{I'm worried about the AC adapter input. All the battery circuitry can be ignored to start, as there is no battery. First I need to follow PRWSRC and VAD...} | |||

| \vspace{0.2in} | |||

| Interestingly, there is a discharge IC. A IC for discharging caps. New to me. They call it a charge pump on the G5934 data sheet, but schematic says Discharge IC... I think same thing. There are discharge pins on the G5934. | |||

| \end{document} | |||

BIN

HP_Pavilion_15_cs0053/pics/what_is_important.jpg

View File

BIN

HP_Pavilion_15_cs0053/resources/AOZ2023PI.pdf

View File

BIN

HP_Pavilion_15_cs0053/resources/DS8068A-03.pdf

View File

BIN

HP_Pavilion_15_cs0053/resources/EDS-5934.pdf

View File

BIN

HP_Pavilion_15_cs0053/resources/HP Pavilion 15 series (Quanta R62) FreeLaptop Schematics Download.pdf

View File

BIN

HP_Pavilion_15_cs0053/resources/as393m.pdf

View File

BIN

HP_Pavilion_15_cs0053/resources/isl88739b.pdf

View File

+ 0

- 94

Sony_PVM_14M4U/docs/.11.tex.swp

View File

| @ -1,94 +0,0 @@ | |||

| \documentclass[11pt]{article} | |||

| %Gummi|065|=) | |||

| \usepackage{graphicx} | |||

| \usepackage{caption} | |||

| \title{\textbf{Sony PVM 14M4U Repair}} | |||

| \author{Steak Electronics} | |||

| \date{} | |||

| \begin{document} | |||

| \maketitle | |||

| \includegraphics[scale=0.3]{../pics/DSCN1101.JPG} | |||

| \captionof{figure}{Barely User Service-able!} | |||

| \section{Start} | |||

| Video 1105.webm shows the problem. Lines moving both vertically (obvious) and horizontally (less obvious, looks diagnolly). | |||

| The second problem, which was more of a problem at the start, was disassembly, and then putting it in a way that it could be repaired. Video from botnet tube (Sony PVM-8041Q Monitor Teardown and Repair-iyJDam0blYA) Shows a repair of a smaller 10 inch model, and you can see, the user is able to easily access parts of the board to repair. However, the 14 inch models are not as simple. The board with all the processing on it (the A board), is on the bottom of the chassis, and to take that out... well video 1104.webm shows what I had to do to get access to the board, while it's powered on. | |||

| \section{CAUTION} | |||

| The tube is extremely damgerous, and I get nervous anytime I go near it. Do NOT try this if you aren't careful. There is also 600V rails on the bottom of board A where the hi voltage (read flyback) transformer is. The only thing in our favor, is that there IS a service manual with some explanations of where everything is. The problem, as I already mentioned, is that actually servicing this device is damn near impossible. | |||

| \section{Repair} | |||

| At first I suspected capacitors had gone bad - due to the failure mode. When it originally failed, it had been working, then suddenly failed. I used an ESR meter but was unable to find any bad caps. This ESR meter is untested, so it's either that there are no bad caps, the bad caps have failed in a way besides high ESR, or that the esr meter doesn't actually work. I do not have a capacitance meter. | |||

| I poked around a bit, but after a few minutes, remembered that voltages should always be checked somewhere early in the repair. Lucky for me, a -15v voltage is showing -25 volts. It being a negative voltage (in my limited knowledge) points to it being for an op amp, and op amps that don't have the right voltage might fail the H and V sync. I will try to fix that and hope there is no other damage. | |||

| \begin{center} | |||

| \includegraphics[scale=0.3]{../pics/DSCN1106.JPG} | |||

| \captionof{figure}{The Rail is listed as -15V...} | |||

| \includegraphics[scale=0.3]{../pics/DSCN1107.JPG} | |||

| \captionof{figure}{Fault. Later on I moved to a Fluke 27 for this, so please bear with the low quality DMM} | |||

| \end{center} | |||

| I looked around, and the output from the PWM is fed into a transformer, where it's rectified into a number of different voltages. The service manual tells all of this. | |||

| \includegraphics[scale=0.6]{../pics/powerboardschematicblockdiagram.jpg} | |||

| \captionof{figure}{PWM to Transformer to Zener} | |||

| It appears that the -15V rail (as well as the +7V rail, both have voltages slightly off. I thought at first, the diodes from the block diagram were zeners (being backwards) but it looks like instead, the problem is before the transformer. I'll have to delve a little deeper to see what is giving an incorrect value. | |||

| \vspace{0.2in} | |||

| \section {Day 2} | |||

| I did some more work on this, but was unable to determine the fault. I think that the fault is before the transformer, but I can't figure out which component has failed. There are not many electrolytic caps before the transformer, and I don't have equipment to check capacitance of other caps. The rail that is marked as 110V before the transformer reads 130, which 'might' be acceptable (my meter is also not true RMS). 110V would refer to Japan's 110V, and for it to be higher in US is expected. Add that to my non true RMS meter, and the error is not glaringly bad. On the other hand, the -22 Volts on the (spec'd) -15V rail definitely is out of spec. I did try a few things, such as isolating the Mains input (i.e. cutting traces on a few spots, and caps) before it entered into the main Rectifier, but I did not find anything conclusive. | |||

| \vspace{0.2in} | |||

| What I know is that there are two rails that are off, the 7V and -15V rails. The 7V rail doesn't appear to be used. I've decided to add in an additional -15V regulator using an LM337, to output 1.5A of -15V. I tried adding another cap on C629, the one of two electrolytics on the -15V rail, but no difference. There are two paths the -15V rail takes in from the mains. One is from the PWM pin B, which has a resistor divider go to S and then down to the pin of the transformer for -15V. One of these resistors might be underspec. | |||

| \vspace{0.2in} | |||

| \begin{center} | |||

| \includegraphics[scale=0.6]{../pics/15vrail.jpg} | |||

| \captionof{figure}{-15V Rail} | |||

| \end{center} | |||

| R605 Measures 380, which may be right (due to it being on board when measuring. it IS close). R604 is .4K (390). Supposed to be 1.2K. But, measuring on board... R607 is .4K again. Seems measuring these in circuit is a losing game. C616 is not a short. R610 is 8.1K. Seems high. It's value should be no higher than 2.2K... Looks like this is a schematic error, as R608 and R609 are the same value resistors and both are similar readings. R610 is in spec. About all I can think, is pulling R604, R605, and R607 and measuring them. | |||

| \vspace{0.2in} | |||

| I'm a bit confused whether the test probe measurements are AC or DC. It says 110, which is after a rectifier, (so DC) but I see AC also on this line, and as well, it's going through a transformer, so it must be AC that is coupling, but the AC is 22V, while the DC is 135V or so. Perhaps the fault is near the bridge diode, and with the coupling capacitors nearby... I tried removing them before, but I don't have equipment to test their values. I didn't see any shorts. I give up - I will put in the LM337 and call it a day. | |||

| \vspace{0.2in} | |||

| One thing that is interesting, is that I really shouldn't need to troubleshoot this at all. This kind of information should be found on a forum or document provided by the manufacturer. Surely they have had this failure mode on other Televisions. A true shortcoming of capitalism, and disposable electronics. It does not endear me to this company in any way. | |||

| \vspace{0.2in} | |||

| \subsection{Day 3} | |||

| I managed to get an LM337 tested and built up on perfboard. As I was soldering wires to the machine, (while unplugged) some caps discharged back into the 115 VOut of the STRS3115 chip as I accidentally moved the probe the wrong way. Oops. Too bad there wasn't a diode there. Now the chip won't output 115V DC. Upon turning the Television on, you can hear the tube attempt to start (sounds like a high voltage ping, which fails to complete, then repeatedly pings - see video). Not enough voltage. | |||

| \vspace{0.2in} | |||

| Good news is, a new chip should fix the 115V rail. There is nothing else on that rail that would've failed (although I can't speak for downstream), so a reasonably straightforward fix. The Television remains on the bench another few days. And some more good news, the LM337 seems to output a near clean -15V. It will be interesting to see what the repaired voltage rail does to the tv output once the 115V rail is back in order. | |||

| \section{Conclusion} | |||

| This was my first Television repair. After I replaced the new chip which I had shorted out earlier, I attempted to turn it on, but the tube would only start for a brief moment before turning itself off (after what seems to be the opto-coupler relay on the power board switched on). At this point, out of the need to clean my desk, I threw in the towel, and tore down the device for what I wanted, giving the rest to recyclers. All in all, it was a learning experience for televisions, and I'm not afraid of CRTs (maybe I should be, though) as much as I was... The lessons to learn in this experience are: | |||

| \begin{itemize} | |||

| \item Be careful of multiple grounds on power supplies like this | |||

| \item Fuses are good. Without a fuse on this, I would've burned something, my probe likely. | |||

| \item Be especially careful when checking voltages in a device like this. Any caps that are charged, will release a shock into other lines if you slip while probing, and that can be the end of your repair right there. Probe as little as possible. | |||

| \end{itemize} | |||

| Upon watching other videos online \footnote{Example being EEVblog \#378, where he attemps a repair of a Yamaha Stereo Amp.} I noticed a few other aspects which would've been useful for my setup (in terms of safety), and also one for repair success. | |||

| \begin{itemize} | |||

| \item Use an isolation transformer for the device under test | |||

| \item Use isolated probes (or make them from the math function and two probes with the ground leads disconnected... Look online if you are not familiar with this). | |||

| \item Use a GFCI on the outlet where the device is connected. (I need one of these for my lab bench). | |||

| \end{itemize} | |||

| And the one note about repair success is, that if I systematically took all (or some of the early ones perhaps, or the ones in the target 15V rail) of the capacitors, and was able to measure with both ESR and a Capacitance meter - which I don't have - I might've been able to find a fault there. Not just electrolytics, but other caps, and of course as Michael Geier wrote in his book on diagnosing electronics, not just caps but anything can fail. TV Try \#1 was not a success but there's no telling what will happen next time. | |||

| \vspace{0.2in} | |||

| Onto the next repair! | |||

| \end{document} | |||