67 changed files with 14096 additions and 1411 deletions

Split View

Diff Options

-

BINHomeSolarDataLogger_Two/datasheets/Atmel-2548-8-bit-AVR-Microcontroller-Battery-Management-ATmega406_Datasheet.pdf

-

+3 -0HomeSolarDataLogger_Two/datasheets/JTAG_NOTES_AVR

-

+59 -0HomeSolarDataLogger_Two/datasheets/VREG_MATH_NOTES

-

BINHomeSolarDataLogger_Two/datasheets/mic4680.pdf

-

BINHomeSolarDataLogger_Two/datasheets/pic16540hv.pdf

-

+4 -0HomeSolarDataLogger_Two/docs/1.aux

-

+197 -0HomeSolarDataLogger_Two/docs/1.log

-

BINHomeSolarDataLogger_Two/docs/1.pdf

-

+37 -0HomeSolarDataLogger_Two/docs/1.tex

-

+133 -0HomeSolarDataLogger_Two/docs/1.tex~

-

+3 -0HomeSolarDataLogger_Two/docs/1.toc

-

+5 -0HomeSolarDataLogger_Two/docs/2.aux

-

+226 -0HomeSolarDataLogger_Two/docs/2.log

-

BINHomeSolarDataLogger_Two/docs/2.pdf

-

+65 -0HomeSolarDataLogger_Two/docs/2.tex

-

+37 -0HomeSolarDataLogger_Two/docs/2.tex~

-

+3 -0HomeSolarDataLogger_Two/docs/2.toc

-

+345 -0HomeSolarDataLogger_Two/pcb/MIC4680_VREG.bak

-

+345 -0HomeSolarDataLogger_Two/pcb/MIC4680_VREG.sch

-

+303 -0HomeSolarDataLogger_Two/pcb/homesolar2-cache.lib

-

+35 -0HomeSolarDataLogger_Two/pcb/homesolar2.bak

-

+117 -0HomeSolarDataLogger_Two/pcb/homesolar2.kicad_pcb

-

+41 -0HomeSolarDataLogger_Two/pcb/homesolar2.pro

-

+35 -0HomeSolarDataLogger_Two/pcb/homesolar2.sch

-

+3 -0HomeSolarDataLogger_Two/pcb/sym-lib-table

-

BINHomeSolarDataLogger_Two/pics/solarlogger_plan.jpg

-

BINHomeSolarDataLogger_Two/pics/solarlogger_plan.xcf

-

+94 -0HomeSolarDataLogger_Two/resources/avr_jtag_pinout.html

-

+2643 -0HomeSolarDataLogger_Two/symbols/MCU_Microchip_ATmega.dcm

-

+7421 -0HomeSolarDataLogger_Two/symbols/MCU_Microchip_ATmega.lib

-

+0 -1TodoList/docs/1.aux

-

+0 -79TodoList/docs/1.log

-

BINTodoList/docs/1.pdf

-

+0 -34TodoList/docs/1.tex

-

+0 -49TodoList/docs/1.tex~

-

+0 -34TodoList/docs/2.tex

-

+0 -49TodoList/docs/2.tex~

-

+0 -59TodoList/docs/3.tex~

-

+0 -62TodoList/docs/4.tex~

-

+0 -65TodoList/docs/5.tex~

-

+0 -67TodoList/docs/6.tex~

-

+0 -69TodoList/docs/7.tex~

-

+16 -0batterycharge_stationdata/TODO

-

+0 -1batterycharge_stationdata/bom/.~lock.BOM_Batterystation.ods#

-

+0 -1batterycharge_stationdata/bom/.~lock.BOM_LTCharger.ods#

-

BINbatterycharge_stationdata/datasheets/13727fbs.pdf

-

BINbatterycharge_stationdata/datasheets/PMEGXX10BEA_PMEGXX10BEV.pdf

-

BINbatterycharge_stationdata/datasheets/ina168.pdf

-

+5 -3batterycharge_stationdata/docs/4.aux

-

+16 -16batterycharge_stationdata/docs/4.log

-

BINbatterycharge_stationdata/docs/4.pdf

-

+21 -0batterycharge_stationdata/docs/4.tex

-

+5 -3batterycharge_stationdata/docs/4.toc

-

+13 -0batterycharge_stationdata/docs/5.aux

-

+311 -0batterycharge_stationdata/docs/5.log

-

BINbatterycharge_stationdata/docs/5.pdf

-

+268 -0batterycharge_stationdata/docs/5.tex

-

+268 -0batterycharge_stationdata/docs/5.tex~

-

+10 -0batterycharge_stationdata/docs/5.toc

-

+66 -32batterycharge_stationdata/pcb/rev2/CurrentSense_INA169.bak

-

+65 -31batterycharge_stationdata/pcb/rev2/CurrentSense_INA169.sch

-

+10 -9batterycharge_stationdata/pcb/rev2/LT1512_universalcharger.bak

-

+9 -8batterycharge_stationdata/pcb/rev2/LT1512_universalcharger.sch

-

+0 -30batterycharge_stationdata/pcb/rev2/batterystation-cache.lib

-

+410 -324batterycharge_stationdata/pcb/rev2/batterystation.kicad_pcb

-

+292 -206batterycharge_stationdata/pcb/rev2/batterystation.kicad_pcb-bak

-

+157 -179batterycharge_stationdata/pcb/rev2/batterystation.net

BIN

HomeSolarDataLogger_Two/datasheets/Atmel-2548-8-bit-AVR-Microcontroller-Battery-Management-ATmega406_Datasheet.pdf

View File

+ 3

- 0

HomeSolarDataLogger_Two/datasheets/JTAG_NOTES_AVR

View File

| @ -0,0 +1,3 @@ | |||

| the jtag pins are in portb section. page 70 | |||

+ 59

- 0

HomeSolarDataLogger_Two/datasheets/VREG_MATH_NOTES

View File

| @ -0,0 +1,59 @@ | |||

| The example resistors in the adjustable section are R1 always 3K | |||

| and R2, varies. You can double R1 and double R2 and get the | |||

| same output voltage. | |||

| So I will use an R1 of 6.8K | |||

| with a base resistor, and an adjustable of | |||

| base | |||

| (would be for 13.5-13.8 according to powerstream sla page) volts) | |||

| so let's do the math | |||

| for 13.65 float voltage. | |||

| 6k( /(13.65/1.23) - 1 ) | |||

| 13.65 / 1.23 - 1 == 10.09756 | |||

| 6k / 10.09756 == 594.31 | |||

| There is a 590 resistor in e24 or something. Let's do that. | |||

| That is base. | |||

| For lowest voltage of 1.2volts (single nicad charged by sun) | |||

| though nicads probably have memory issues, but they are cheap | |||

| so who cares... (I think nimh might be better?) | |||

| 1.2 = 1.23( 6k/??? + 1) | |||

| So solve for R2 which is unknown | |||

| However my earlier math is wrong, since I need a 5900 resistor | |||

| 13.65 / 1.23 - 1 == 10.09756 | |||

| 5900 / 10.09756 == 584.29 | |||

| So still a 590 resistor... Close as we can get. Well, | |||

| there is a 583 on my chart, so | |||

| 5900 | |||

| 583 | |||

| Base is 583, 5900 is R1 | |||

| Now what is the adjustable. | |||

| Solve for R2, and remember you need the difference | |||

| And can't go below reference... | |||

| R2 == 5900 / (1.3/1.23 - 1) | |||

| 1.3/1.23 - 1 == 0.0569 | |||

| 5900 / 0.0569 == 103690 | |||

| Quite a difference. We need to jump from 100K to 583. | |||

| So I would add a 100K and that should get me close to 1.4 volts. | |||

| Hopefully close enough. Done. | |||

BIN

HomeSolarDataLogger_Two/datasheets/mic4680.pdf

View File

BIN

HomeSolarDataLogger_Two/datasheets/pic16540hv.pdf

View File

+ 4

- 0

HomeSolarDataLogger_Two/docs/1.aux

View File

| @ -0,0 +1,4 @@ | |||

| \relax | |||

| \@writefile{toc}{\contentsline {section}{\numberline {1}Overview}{1}} | |||

| \@writefile{toc}{\contentsline {section}{\numberline {2}Chip Hunting}{1}} | |||

| \@writefile{toc}{\contentsline {subsection}{\numberline {2.1}Board considerations}{1}} | |||

+ 197

- 0

HomeSolarDataLogger_Two/docs/1.log

View File

| @ -0,0 +1,197 @@ | |||

| This is pdfTeX, Version 3.14159265-2.6-1.40.15 (TeX Live 2015/dev/Debian) (preloaded format=pdflatex 2018.11.28) 29 APR 2019 23:02 | |||

| entering extended mode | |||

| restricted \write18 enabled. | |||

| %&-line parsing enabled. | |||

| **/home/layoutdev/Desktop/code/documentation_general/Electronics_Projects_2019/ | |||

| HomeSolarDataLogger_Two/docs/1.tex | |||

| (/home/layoutdev/Desktop/code/documentation_general/Electronics_Projects_2019/H | |||

| omeSolarDataLogger_Two/docs/1.tex | |||

| LaTeX2e <2014/05/01> | |||

| Babel <3.9l> and hyphenation patterns for 2 languages loaded. | |||

| (/usr/share/texlive/texmf-dist/tex/latex/base/article.cls | |||

| Document Class: article 2014/09/29 v1.4h Standard LaTeX document class | |||

| (/usr/share/texlive/texmf-dist/tex/latex/base/size11.clo | |||

| File: size11.clo 2014/09/29 v1.4h Standard LaTeX file (size option) | |||

| ) | |||

| \c@part=\count79 | |||

| \c@section=\count80 | |||

| \c@subsection=\count81 | |||

| \c@subsubsection=\count82 | |||

| \c@paragraph=\count83 | |||

| \c@subparagraph=\count84 | |||

| \c@figure=\count85 | |||

| \c@table=\count86 | |||

| \abovecaptionskip=\skip41 | |||

| \belowcaptionskip=\skip42 | |||

| \bibindent=\dimen102 | |||

| ) | |||

| (/usr/share/texlive/texmf-dist/tex/latex/graphics/graphicx.sty | |||

| Package: graphicx 2014/04/25 v1.0g Enhanced LaTeX Graphics (DPC,SPQR) | |||

| (/usr/share/texlive/texmf-dist/tex/latex/graphics/keyval.sty | |||

| Package: keyval 2014/05/08 v1.15 key=value parser (DPC) | |||

| \KV@toks@=\toks14 | |||

| ) | |||

| (/usr/share/texlive/texmf-dist/tex/latex/graphics/graphics.sty | |||

| Package: graphics 2009/02/05 v1.0o Standard LaTeX Graphics (DPC,SPQR) | |||

| (/usr/share/texlive/texmf-dist/tex/latex/graphics/trig.sty | |||

| Package: trig 1999/03/16 v1.09 sin cos tan (DPC) | |||

| ) | |||

| (/usr/share/texlive/texmf-dist/tex/latex/latexconfig/graphics.cfg | |||

| File: graphics.cfg 2010/04/23 v1.9 graphics configuration of TeX Live | |||

| ) | |||

| Package graphics Info: Driver file: pdftex.def on input line 91. | |||

| (/usr/share/texlive/texmf-dist/tex/latex/pdftex-def/pdftex.def | |||

| File: pdftex.def 2011/05/27 v0.06d Graphics/color for pdfTeX | |||

| (/usr/share/texlive/texmf-dist/tex/generic/oberdiek/infwarerr.sty | |||

| Package: infwarerr 2010/04/08 v1.3 Providing info/warning/error messages (HO) | |||

| ) | |||

| (/usr/share/texlive/texmf-dist/tex/generic/oberdiek/ltxcmds.sty | |||

| Package: ltxcmds 2011/11/09 v1.22 LaTeX kernel commands for general use (HO) | |||

| ) | |||

| \Gread@gobject=\count87 | |||

| )) | |||

| \Gin@req@height=\dimen103 | |||

| \Gin@req@width=\dimen104 | |||

| ) | |||

| (/usr/share/texlive/texmf-dist/tex/latex/caption/caption.sty | |||

| Package: caption 2013/05/02 v3.3-89 Customizing captions (AR) | |||

| (/usr/share/texlive/texmf-dist/tex/latex/caption/caption3.sty | |||

| Package: caption3 2013/05/02 v1.6-88 caption3 kernel (AR) | |||

| Package caption3 Info: TeX engine: e-TeX on input line 57. | |||

| \captionmargin=\dimen105 | |||

| \captionmargin@=\dimen106 | |||

| \captionwidth=\dimen107 | |||

| \caption@tempdima=\dimen108 | |||

| \caption@indent=\dimen109 | |||

| \caption@parindent=\dimen110 | |||

| \caption@hangindent=\dimen111 | |||

| ) | |||

| \c@ContinuedFloat=\count88 | |||

| ) (./1.aux) | |||

| \openout1 = `1.aux'. | |||

| LaTeX Font Info: Checking defaults for OML/cmm/m/it on input line 9. | |||

| LaTeX Font Info: ... okay on input line 9. | |||

| LaTeX Font Info: Checking defaults for T1/cmr/m/n on input line 9. | |||

| LaTeX Font Info: ... okay on input line 9. | |||

| LaTeX Font Info: Checking defaults for OT1/cmr/m/n on input line 9. | |||

| LaTeX Font Info: ... okay on input line 9. | |||

| LaTeX Font Info: Checking defaults for OMS/cmsy/m/n on input line 9. | |||

| LaTeX Font Info: ... okay on input line 9. | |||

| LaTeX Font Info: Checking defaults for OMX/cmex/m/n on input line 9. | |||

| LaTeX Font Info: ... okay on input line 9. | |||

| LaTeX Font Info: Checking defaults for U/cmr/m/n on input line 9. | |||

| LaTeX Font Info: ... okay on input line 9. | |||

| (/usr/share/texlive/texmf-dist/tex/context/base/supp-pdf.mkii | |||

| [Loading MPS to PDF converter (version 2006.09.02).] | |||

| \scratchcounter=\count89 | |||

| \scratchdimen=\dimen112 | |||

| \scratchbox=\box26 | |||

| \nofMPsegments=\count90 | |||

| \nofMParguments=\count91 | |||

| \everyMPshowfont=\toks15 | |||

| \MPscratchCnt=\count92 | |||

| \MPscratchDim=\dimen113 | |||

| \MPnumerator=\count93 | |||

| \makeMPintoPDFobject=\count94 | |||

| \everyMPtoPDFconversion=\toks16 | |||

| ) (/usr/share/texlive/texmf-dist/tex/generic/oberdiek/pdftexcmds.sty | |||

| Package: pdftexcmds 2011/11/29 v0.20 Utility functions of pdfTeX for LuaTeX (HO | |||

| ) | |||

| (/usr/share/texlive/texmf-dist/tex/generic/oberdiek/ifluatex.sty | |||

| Package: ifluatex 2010/03/01 v1.3 Provides the ifluatex switch (HO) | |||

| Package ifluatex Info: LuaTeX not detected. | |||

| ) | |||

| (/usr/share/texlive/texmf-dist/tex/generic/oberdiek/ifpdf.sty | |||

| Package: ifpdf 2011/01/30 v2.3 Provides the ifpdf switch (HO) | |||

| Package ifpdf Info: pdfTeX in PDF mode is detected. | |||

| ) | |||

| Package pdftexcmds Info: LuaTeX not detected. | |||

| Package pdftexcmds Info: \pdf@primitive is available. | |||

| Package pdftexcmds Info: \pdf@ifprimitive is available. | |||

| Package pdftexcmds Info: \pdfdraftmode found. | |||

| ) | |||

| (/usr/share/texlive/texmf-dist/tex/latex/oberdiek/epstopdf-base.sty | |||

| Package: epstopdf-base 2010/02/09 v2.5 Base part for package epstopdf | |||

| (/usr/share/texlive/texmf-dist/tex/latex/oberdiek/grfext.sty | |||

| Package: grfext 2010/08/19 v1.1 Manage graphics extensions (HO) | |||

| (/usr/share/texlive/texmf-dist/tex/generic/oberdiek/kvdefinekeys.sty | |||

| Package: kvdefinekeys 2011/04/07 v1.3 Define keys (HO) | |||

| )) | |||

| (/usr/share/texlive/texmf-dist/tex/latex/oberdiek/kvoptions.sty | |||

| Package: kvoptions 2011/06/30 v3.11 Key value format for package options (HO) | |||

| (/usr/share/texlive/texmf-dist/tex/generic/oberdiek/kvsetkeys.sty | |||

| Package: kvsetkeys 2012/04/25 v1.16 Key value parser (HO) | |||

| (/usr/share/texlive/texmf-dist/tex/generic/oberdiek/etexcmds.sty | |||

| Package: etexcmds 2011/02/16 v1.5 Avoid name clashes with e-TeX commands (HO) | |||

| Package etexcmds Info: Could not find \expanded. | |||

| (etexcmds) That can mean that you are not using pdfTeX 1.50 or | |||

| (etexcmds) that some package has redefined \expanded. | |||

| (etexcmds) In the latter case, load this package earlier. | |||

| ))) | |||

| Package grfext Info: Graphics extension search list: | |||

| (grfext) [.png,.pdf,.jpg,.mps,.jpeg,.jbig2,.jb2,.PNG,.PDF,.JPG,.JPE | |||

| G,.JBIG2,.JB2,.eps] | |||

| (grfext) \AppendGraphicsExtensions on input line 452. | |||

| (/usr/share/texlive/texmf-dist/tex/latex/latexconfig/epstopdf-sys.cfg | |||

| File: epstopdf-sys.cfg 2010/07/13 v1.3 Configuration of (r)epstopdf for TeX Liv | |||

| e | |||

| )) | |||

| Package caption Info: Begin \AtBeginDocument code. | |||

| Package caption Info: End \AtBeginDocument code. | |||

| LaTeX Font Info: External font `cmex10' loaded for size | |||

| (Font) <12> on input line 11. | |||

| LaTeX Font Info: External font `cmex10' loaded for size | |||

| (Font) <8> on input line 11. | |||

| LaTeX Font Info: External font `cmex10' loaded for size | |||

| (Font) <6> on input line 11. | |||

| (./1.toc | |||

| LaTeX Font Info: External font `cmex10' loaded for size | |||

| (Font) <10.95> on input line 3. | |||

| ) | |||

| \tf@toc=\write3 | |||

| \openout3 = `1.toc'. | |||

| Overfull \hbox (2.44542pt too wide) in paragraph at lines 18--19 | |||

| \OT1/cmr/m/n/10.95 Sorting by cheap-est buck boost reg-u-la-tors, I've found a | |||

| mi-crel chip, MIC4680, | |||

| [] | |||

| [1 | |||

| {/var/lib/texmf/fonts/map/pdftex/updmap/pdftex.map}] [2] (./1.aux) ) | |||

| Here is how much of TeX's memory you used: | |||

| 2538 strings out of 495020 | |||

| 40425 string characters out of 6181323 | |||

| 94797 words of memory out of 5000000 | |||

| 5754 multiletter control sequences out of 15000+600000 | |||

| 9118 words of font info for 32 fonts, out of 8000000 for 9000 | |||

| 14 hyphenation exceptions out of 8191 | |||

| 38i,6n,38p,496b,189s stack positions out of 5000i,500n,10000p,200000b,80000s | |||

| </usr/share | |||

| /texlive/texmf-dist/fonts/type1/public/amsfonts/cm/cmbx10.pfb></usr/share/texli | |||

| ve/texmf-dist/fonts/type1/public/amsfonts/cm/cmbx12.pfb></usr/share/texlive/tex | |||

| mf-dist/fonts/type1/public/amsfonts/cm/cmr10.pfb></usr/share/texlive/texmf-dist | |||

| /fonts/type1/public/amsfonts/cm/cmr12.pfb> | |||

| Output written on 1.pdf (2 pages, 56952 bytes). | |||

| PDF statistics: | |||

| 27 PDF objects out of 1000 (max. 8388607) | |||

| 18 compressed objects within 1 object stream | |||

| 0 named destinations out of 1000 (max. 500000) | |||

| 1 words of extra memory for PDF output out of 10000 (max. 10000000) | |||

BIN

HomeSolarDataLogger_Two/docs/1.pdf

View File

+ 37

- 0

HomeSolarDataLogger_Two/docs/1.tex

View File

| @ -0,0 +1,37 @@ | |||

| \documentclass[11pt]{article} | |||

| %Gummi|065|=) | |||

| \usepackage{graphicx} | |||

| \usepackage{caption} | |||

| \title{\textbf{Solar Charger Project}} | |||

| \author{Steak Electronics} | |||

| \date{} | |||

| \begin{document} | |||

| \maketitle | |||

| \tableofcontents | |||

| \section{Overview} | |||

| Want to charge a lead battery from a solar panel, and run some load on the battery occasionally. Want to monitor the load, and the charge of the panel. | |||

| \section{Chip Hunting} | |||

| Sorting by cheapest buck boost regulators, I've found a micrel chip, MIC4680, which is a simple buck reg. It can be adjustable, so I will take advantage of that with another slide pot, and use it to charge different battery types. These regs are ~\$2. The next realistic option I see is around 5-6 which are the true buck/boost switching regs. | |||

| Not sure how I will handle overcurrent. Probably a fuse, or ptc. Too much current will blow the fuse. Don't do that. | |||

| Let's start building the board. | |||

| \subsection{Board considerations} | |||

| Input will be any number of solar cells, in series and or parallel. They will go to the vreg. The vreg will go to the battery, which in turn will have a load, of a micro (probably a nano on sleep mode). But actually, I might want a micro that can operate at up to 14 volts... So a nano might not work. Looks like there is a high voltage PIC and Atmega, but the Atmega is obsolete :/ | |||

| So cheapest is the Pic16. Might try that. It can handle up to 15 volts, which should be safe, with the regulator offering a float voltage (but only a float voltage. Unfortunately, the AVR was up to 18v...) | |||

| Unfortunateyl the PIC is eprom (i.e. UV erasable) only or One time programmed OTP only. Ugh. | |||

| \end{document} | |||

+ 133

- 0

HomeSolarDataLogger_Two/docs/1.tex~

View File

| @ -0,0 +1,133 @@ | |||

| \documentclass[11pt]{article} | |||

| %Gummi|065|=) | |||

| \usepackage{graphicx} | |||

| \usepackage{caption} | |||

| \title{\textbf{BatteryMonitorBoard}} | |||

| \author{Steak Electronics} | |||

| \date{} | |||

| \begin{document} | |||

| \maketitle | |||

| \tableofcontents | |||

| \section{Overview} | |||

| \section{Chip Hunting} | |||

| Need to find a chip for battery charging. Some sheets have been saved. I looked at TI primarily. Though considered one AD/LTC. BQ2954 is out of the question as its too complex in its application circuit. THe BQ2000 is a 8 pin DIP and seems like a good start. That will cover nicad/nimh, and lithium batteries. | |||

| Though the BQ2000 is a bit of a mess as well. Data sheet has a complex circuit. There is a simpler one here: | |||

| http://www.ti.com/lit/pdf/sluu007 | |||

| and | |||

| https://electronics.stackexchange.com/questions/95970/how-to-use-battery-charge-controller-bq2002n | |||

| Regardless of the contents of that post, the fact is, the chip requires a lot of stuff. | |||

| https://www.st.com/content/ccc/resource/technical/document/datasheet/df/b9/e6/5b/ec/92/45/ed/CD00132951.pdf/files/CD00132951.pdf/jcr:content/translations/en.CD00132951.pdf | |||

| This chip: stc4054, is extremely simple. Limited to 1 lithium cell (so only 4.2 volts max) but application circuit is lean, and it has a shutdown pin, so you can turn off the charger. Price is the cheapest as well, at 1.50 for 1. | |||

| That looks hopeful. Why not multiple? | |||

| Need to remember to be careful of 4.1 lithium batteries. Most chargers are 4.2, and its easy to forget that there is a difference. | |||

| MCP73826 is another reasonable option. Slightly more complex, but not by much. | |||

| RT9526A is also simple. Let's start with the st chip. | |||

| Looks like the voltage on that pin should be between 1.2 and 2.4 in order to turn it off. Below 1.2 it is on, and monitoring current. Above 1.2 but below 2.4 it is off. above 2.4 it's putting 35ua into the battery. I think. | |||

| Also like the LTC1734, which is lithium / nicad. But expensive at 3-4 dollars. Don't see any lead acid battery chargers on digi that aren't being obsoleted. There's not one. I did see some on manufacturer's pages though. Just not here. | |||

| There is one microchip one (lead acid) based on a pic. App circuit is complex. | |||

| AN1015 is the app note. | |||

| So need a lead, and nicd charger still. | |||

| Tomorrow I'd like to look at maxim. I see this: | |||

| https://www.maximintegrated.com/en/products/power/battery-management/MAX1772.html | |||

| But the application circuit is too much for what I want to deal with. | |||

| Seems lead acid battery chargers are not as common as they must've been before. | |||

| Onsemi is only lithium batteries. | |||

| Mouser has only universal chargers, no lead. But universal includes lead. | |||

| let's check linear. LT1510 is an 8 pin simple device. Though it's nicad and lithium only. It says it can do lead in table, but not in datasheet. | |||

| lt1510 would work for nicad. data sheet figure 6 has a circuit for nicad. | |||

| What about lead? | |||

| lt1513 does the three main types: nicd,li-ion,lead | |||

| At a cost of \$10. | |||

| At digi, the bq2031 is the only lead battery chip (not multi type) that is in production. Not much choice. EDIT: actually that is not | |||

| recommended for new designs either. | |||

| http://www.eevblog.com/forum/beginners/mc34063-battery-charger/msg1378671/\#msg1378671 | |||

| Here he uses a boost regulator to power a battery. Essentially just setting the voltage. | |||

| http://www.eevblog.com/forum/projects/switching-lead-acid-battery-charger-ic/msg806972/\#msg806972 | |||

| Here is some better advice. | |||

| quote: | |||

| \begin{verbatim} | |||

| I'd recommend just float charging. It takes only a little longer | |||

| and is easier on the batteries. You will need to limit the initial | |||

| charge current to about 0.1 C (so 2 A for a 20 AH battery). The | |||

| easiest way to do this is a constant current/ constant voltage | |||

| power supply. Set the current limit to the desired charge current, | |||

| and the voltage to the float voltage (13.8 V adjusted for | |||

| temperature if needed). The voltage on the battery will slowly | |||

| increase over time until it reaches ~13.8 V, then the current will | |||

| slowly drop over time until it reaches nearly zero. At that point, | |||

| the battery is fully charged and you can either remove the charger | |||

| or just leave it on. | |||

| \end{verbatim} | |||

| Which is what I did with my solar battery charger, and it worked well. So I suppose there is no need for anything more than a vreg for lead batteries. This time I will go to the recommended 13.8 instead of what I had before (around 12) and I will do the same trickle charge method. Simple. Done. | |||

| May use 1512 instead. \$5 in 150 quantity. Hm... | |||

| \$10 in single. | |||

| That would cover lead, nicad. | |||

| Will need jumpers on R1 and R2 depending on what battery type. According to data sheet, li-ion the divider is a float voltage. In nicd, it is a top limit. | |||

| OK, i've decided: | |||

| \subsection{Part Selection Summary} | |||

| LT1512, and STC4054. | |||

| For starters, I will use stc as lithium and lt as nicad / lead. | |||

| this will avoid the worry of jumpers, and what not. Later I can be flexible. | |||

| Now onto other parts. I need some way to monitor the current, and of course a voltage tap. | |||

| Where to put current sense? I think before the battery. | |||

| I should put some jumpers in, so I can isolate everything though. I dont' want to mix circuits at the start. So isolate the charger from the op amp and sense, at first. | |||

| Let's go with the basic differential op amp in microchip an1332. I need a vreg supply (linear) at 15.5 volts, for the op amp, so it's above the lead battery voltage. Simplest two switchers I see are lm2577 or the mk3608. The mk is easier to use. | |||

| With that we have: | |||

| \begin{itemize} | |||

| \item Battery charger x 2 | |||

| \item voltage monitor x 2 | |||

| \item current monitor x 2 | |||

| \item ethernet (using off the shelf enc modules for now, but maybe | |||

| on board later). | |||

| \item microcontroller (nano) | |||

| \item temperature monitor (something like max6675 looks nice. can put on board, without difficulty). | |||

| \item additional taps into adc, and some op amps and current shunts not populated to be used as extra current - voltage converters. At least two. Put on modular schematic. | |||

| \end{itemize} | |||

| I also want a general current and voltage monitor. I want | |||

| to be able to watch the load on a battery, and record that as well... | |||

| Perhaps that will be separate. I might want to grab some off the shelf | |||

| current / voltage monitoring stuff, or just throw a few op amps with breakouts on the board. | |||

| Let's build. | |||

| Keep all schematics modular! | |||

| \end{document} | |||

+ 3

- 0

HomeSolarDataLogger_Two/docs/1.toc

View File

| @ -0,0 +1,3 @@ | |||

| \contentsline {section}{\numberline {1}Overview}{1} | |||

| \contentsline {section}{\numberline {2}Chip Hunting}{1} | |||

| \contentsline {subsection}{\numberline {2.1}Board considerations}{1} | |||

+ 5

- 0

HomeSolarDataLogger_Two/docs/2.aux

View File

| @ -0,0 +1,5 @@ | |||

| \relax | |||

| \@writefile{toc}{\contentsline {section}{\numberline {1}Overview}{1}} | |||

| \@writefile{toc}{\contentsline {section}{\numberline {2}Chip Hunting}{1}} | |||

| \@writefile{toc}{\contentsline {subsection}{\numberline {2.1}Board considerations}{2}} | |||

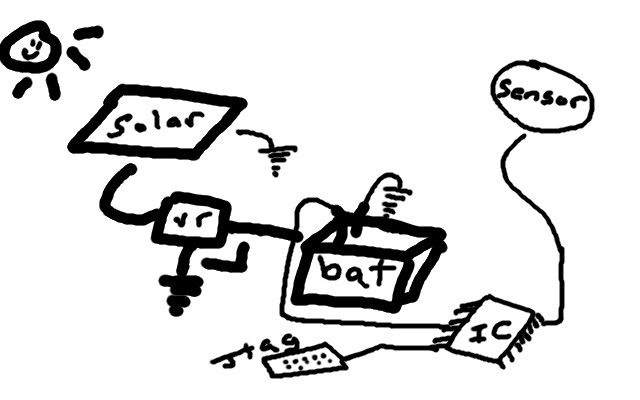

| \@writefile{lof}{\contentsline {figure}{\numberline {1}{\ignorespaces Solar Logger outline. Self sufficient sensors\relax }}{3}} | |||

+ 226

- 0

HomeSolarDataLogger_Two/docs/2.log

View File

| @ -0,0 +1,226 @@ | |||

| This is pdfTeX, Version 3.14159265-2.6-1.40.15 (TeX Live 2015/dev/Debian) (preloaded format=pdflatex 2018.11.28) 30 APR 2019 00:29 | |||

| entering extended mode | |||

| restricted \write18 enabled. | |||

| %&-line parsing enabled. | |||

| **/home/layoutdev/Desktop/code/documentation_general/Electronics_Projects_2019/ | |||

| HomeSolarDataLogger_Two/docs/2.tex | |||

| (/home/layoutdev/Desktop/code/documentation_general/Electronics_Projects_2019/H | |||

| omeSolarDataLogger_Two/docs/2.tex | |||

| LaTeX2e <2014/05/01> | |||

| Babel <3.9l> and hyphenation patterns for 2 languages loaded. | |||

| (/usr/share/texlive/texmf-dist/tex/latex/base/article.cls | |||

| Document Class: article 2014/09/29 v1.4h Standard LaTeX document class | |||

| (/usr/share/texlive/texmf-dist/tex/latex/base/size11.clo | |||

| File: size11.clo 2014/09/29 v1.4h Standard LaTeX file (size option) | |||

| ) | |||

| \c@part=\count79 | |||

| \c@section=\count80 | |||

| \c@subsection=\count81 | |||

| \c@subsubsection=\count82 | |||

| \c@paragraph=\count83 | |||

| \c@subparagraph=\count84 | |||

| \c@figure=\count85 | |||

| \c@table=\count86 | |||

| \abovecaptionskip=\skip41 | |||

| \belowcaptionskip=\skip42 | |||

| \bibindent=\dimen102 | |||

| ) | |||

| (/usr/share/texlive/texmf-dist/tex/latex/graphics/graphicx.sty | |||

| Package: graphicx 2014/04/25 v1.0g Enhanced LaTeX Graphics (DPC,SPQR) | |||

| (/usr/share/texlive/texmf-dist/tex/latex/graphics/keyval.sty | |||

| Package: keyval 2014/05/08 v1.15 key=value parser (DPC) | |||

| \KV@toks@=\toks14 | |||

| ) | |||

| (/usr/share/texlive/texmf-dist/tex/latex/graphics/graphics.sty | |||

| Package: graphics 2009/02/05 v1.0o Standard LaTeX Graphics (DPC,SPQR) | |||

| (/usr/share/texlive/texmf-dist/tex/latex/graphics/trig.sty | |||

| Package: trig 1999/03/16 v1.09 sin cos tan (DPC) | |||

| ) | |||

| (/usr/share/texlive/texmf-dist/tex/latex/latexconfig/graphics.cfg | |||

| File: graphics.cfg 2010/04/23 v1.9 graphics configuration of TeX Live | |||

| ) | |||

| Package graphics Info: Driver file: pdftex.def on input line 91. | |||

| (/usr/share/texlive/texmf-dist/tex/latex/pdftex-def/pdftex.def | |||

| File: pdftex.def 2011/05/27 v0.06d Graphics/color for pdfTeX | |||

| (/usr/share/texlive/texmf-dist/tex/generic/oberdiek/infwarerr.sty | |||

| Package: infwarerr 2010/04/08 v1.3 Providing info/warning/error messages (HO) | |||

| ) | |||

| (/usr/share/texlive/texmf-dist/tex/generic/oberdiek/ltxcmds.sty | |||

| Package: ltxcmds 2011/11/09 v1.22 LaTeX kernel commands for general use (HO) | |||

| ) | |||

| \Gread@gobject=\count87 | |||

| )) | |||

| \Gin@req@height=\dimen103 | |||

| \Gin@req@width=\dimen104 | |||

| ) | |||

| (/usr/share/texlive/texmf-dist/tex/latex/caption/caption.sty | |||

| Package: caption 2013/05/02 v3.3-89 Customizing captions (AR) | |||

| (/usr/share/texlive/texmf-dist/tex/latex/caption/caption3.sty | |||

| Package: caption3 2013/05/02 v1.6-88 caption3 kernel (AR) | |||

| Package caption3 Info: TeX engine: e-TeX on input line 57. | |||

| \captionmargin=\dimen105 | |||

| \captionmargin@=\dimen106 | |||

| \captionwidth=\dimen107 | |||

| \caption@tempdima=\dimen108 | |||

| \caption@indent=\dimen109 | |||

| \caption@parindent=\dimen110 | |||

| \caption@hangindent=\dimen111 | |||

| ) | |||

| \c@ContinuedFloat=\count88 | |||

| ) (./2.aux) | |||

| \openout1 = `2.aux'. | |||

| LaTeX Font Info: Checking defaults for OML/cmm/m/it on input line 9. | |||

| LaTeX Font Info: ... okay on input line 9. | |||

| LaTeX Font Info: Checking defaults for T1/cmr/m/n on input line 9. | |||

| LaTeX Font Info: ... okay on input line 9. | |||

| LaTeX Font Info: Checking defaults for OT1/cmr/m/n on input line 9. | |||

| LaTeX Font Info: ... okay on input line 9. | |||

| LaTeX Font Info: Checking defaults for OMS/cmsy/m/n on input line 9. | |||

| LaTeX Font Info: ... okay on input line 9. | |||

| LaTeX Font Info: Checking defaults for OMX/cmex/m/n on input line 9. | |||

| LaTeX Font Info: ... okay on input line 9. | |||

| LaTeX Font Info: Checking defaults for U/cmr/m/n on input line 9. | |||

| LaTeX Font Info: ... okay on input line 9. | |||

| (/usr/share/texlive/texmf-dist/tex/context/base/supp-pdf.mkii | |||

| [Loading MPS to PDF converter (version 2006.09.02).] | |||

| \scratchcounter=\count89 | |||

| \scratchdimen=\dimen112 | |||

| \scratchbox=\box26 | |||

| \nofMPsegments=\count90 | |||

| \nofMParguments=\count91 | |||

| \everyMPshowfont=\toks15 | |||

| \MPscratchCnt=\count92 | |||

| \MPscratchDim=\dimen113 | |||

| \MPnumerator=\count93 | |||

| \makeMPintoPDFobject=\count94 | |||

| \everyMPtoPDFconversion=\toks16 | |||

| ) (/usr/share/texlive/texmf-dist/tex/generic/oberdiek/pdftexcmds.sty | |||

| Package: pdftexcmds 2011/11/29 v0.20 Utility functions of pdfTeX for LuaTeX (HO | |||

| ) | |||

| (/usr/share/texlive/texmf-dist/tex/generic/oberdiek/ifluatex.sty | |||

| Package: ifluatex 2010/03/01 v1.3 Provides the ifluatex switch (HO) | |||

| Package ifluatex Info: LuaTeX not detected. | |||

| ) | |||

| (/usr/share/texlive/texmf-dist/tex/generic/oberdiek/ifpdf.sty | |||

| Package: ifpdf 2011/01/30 v2.3 Provides the ifpdf switch (HO) | |||

| Package ifpdf Info: pdfTeX in PDF mode is detected. | |||

| ) | |||

| Package pdftexcmds Info: LuaTeX not detected. | |||

| Package pdftexcmds Info: \pdf@primitive is available. | |||

| Package pdftexcmds Info: \pdf@ifprimitive is available. | |||

| Package pdftexcmds Info: \pdfdraftmode found. | |||

| ) | |||

| (/usr/share/texlive/texmf-dist/tex/latex/oberdiek/epstopdf-base.sty | |||

| Package: epstopdf-base 2010/02/09 v2.5 Base part for package epstopdf | |||

| (/usr/share/texlive/texmf-dist/tex/latex/oberdiek/grfext.sty | |||

| Package: grfext 2010/08/19 v1.1 Manage graphics extensions (HO) | |||

| (/usr/share/texlive/texmf-dist/tex/generic/oberdiek/kvdefinekeys.sty | |||

| Package: kvdefinekeys 2011/04/07 v1.3 Define keys (HO) | |||

| )) | |||

| (/usr/share/texlive/texmf-dist/tex/latex/oberdiek/kvoptions.sty | |||

| Package: kvoptions 2011/06/30 v3.11 Key value format for package options (HO) | |||

| (/usr/share/texlive/texmf-dist/tex/generic/oberdiek/kvsetkeys.sty | |||

| Package: kvsetkeys 2012/04/25 v1.16 Key value parser (HO) | |||

| (/usr/share/texlive/texmf-dist/tex/generic/oberdiek/etexcmds.sty | |||

| Package: etexcmds 2011/02/16 v1.5 Avoid name clashes with e-TeX commands (HO) | |||

| Package etexcmds Info: Could not find \expanded. | |||

| (etexcmds) That can mean that you are not using pdfTeX 1.50 or | |||

| (etexcmds) that some package has redefined \expanded. | |||

| (etexcmds) In the latter case, load this package earlier. | |||

| ))) | |||

| Package grfext Info: Graphics extension search list: | |||

| (grfext) [.png,.pdf,.jpg,.mps,.jpeg,.jbig2,.jb2,.PNG,.PDF,.JPG,.JPE | |||

| G,.JBIG2,.JB2,.eps] | |||

| (grfext) \AppendGraphicsExtensions on input line 452. | |||

| (/usr/share/texlive/texmf-dist/tex/latex/latexconfig/epstopdf-sys.cfg | |||

| File: epstopdf-sys.cfg 2010/07/13 v1.3 Configuration of (r)epstopdf for TeX Liv | |||

| e | |||

| )) | |||

| Package caption Info: Begin \AtBeginDocument code. | |||

| Package caption Info: End \AtBeginDocument code. | |||

| LaTeX Font Info: External font `cmex10' loaded for size | |||

| (Font) <12> on input line 11. | |||

| LaTeX Font Info: External font `cmex10' loaded for size | |||

| (Font) <8> on input line 11. | |||

| LaTeX Font Info: External font `cmex10' loaded for size | |||

| (Font) <6> on input line 11. | |||

| (./2.toc | |||

| LaTeX Font Info: External font `cmex10' loaded for size | |||

| (Font) <10.95> on input line 3. | |||

| ) | |||

| \tf@toc=\write3 | |||

| \openout3 = `2.toc'. | |||

| Overfull \hbox (2.44542pt too wide) in paragraph at lines 19--20 | |||

| \OT1/cmr/m/n/10.95 Sorting by cheap-est buck boost reg-u-la-tors, I've found a | |||

| mi-crel chip, MIC4680, | |||

| [] | |||

| [1 | |||

| {/var/lib/texmf/fonts/map/pdftex/updmap/pdftex.map}] | |||

| LaTeX Font Info: Try loading font information for OMS+cmr on input line 38. | |||

| (/usr/share/texlive/texmf-dist/tex/latex/base/omscmr.fd | |||

| File: omscmr.fd 2014/09/29 v2.5h Standard LaTeX font definitions | |||

| ) | |||

| LaTeX Font Info: Font shape `OMS/cmr/m/n' in size <10.95> not available | |||

| (Font) Font shape `OMS/cmsy/m/n' tried instead on input line 38. | |||

| [2] | |||

| <../pics/solarlogger_plan.jpg, id=14, 642.4pt x 401.5pt> | |||

| File: ../pics/solarlogger_plan.jpg Graphic file (type jpg) | |||

| <use ../pics/solarlogger_plan.jpg> | |||

| Package pdftex.def Info: ../pics/solarlogger_plan.jpg used on input line 54. | |||

| (pdftex.def) Requested size: 321.19922pt x 200.7495pt. | |||

| Package caption Warning: \captionsetup{type*=...} or \captionof | |||

| (caption) outside box or environment on input line 55. | |||

| See the caption package documentation for explanation. | |||

| Overfull \hbox (2.16733pt too wide) in paragraph at lines 62--62 | |||

| []\OT1/cmtt/m/n/10.95 Connectors_Molex:Molex_MiniFit-JR-5556-02A_2x01x4.20mm_St | |||

| raight[] | |||

| [] | |||

| [3 <../pics/solarlogger_plan.jpg>] (./2.aux) ) | |||

| Here is how much of TeX's memory you used: | |||

| 2569 strings out of 495020 | |||

| 40987 string characters out of 6181323 | |||

| 95797 words of memory out of 5000000 | |||

| 5778 multiletter control sequences out of 15000+600000 | |||

| 9286 words of font info for 33 fonts, out of 8000000 for 9000 | |||

| 14 hyphenation exceptions out of 8191 | |||

| 38i,6n,38p,824b,189s stack positions out of 5000i,500n,10000p,200000b,80000s | |||

| </usr/share/texlive/texmf-dist/fo | |||

| nts/type1/public/amsfonts/cm/cmbx10.pfb></usr/share/texlive/texmf-dist/fonts/ty | |||

| pe1/public/amsfonts/cm/cmbx12.pfb></usr/share/texlive/texmf-dist/fonts/type1/pu | |||

| blic/amsfonts/cm/cmr10.pfb></usr/share/texlive/texmf-dist/fonts/type1/public/am | |||

| sfonts/cm/cmr12.pfb></usr/share/texlive/texmf-dist/fonts/type1/public/amsfonts/ | |||

| cm/cmsy10.pfb></usr/share/texlive/texmf-dist/fonts/type1/public/amsfonts/cm/cmt | |||

| t10.pfb> | |||

| Output written on 2.pdf (3 pages, 120092 bytes). | |||

| PDF statistics: | |||

| 39 PDF objects out of 1000 (max. 8388607) | |||

| 26 compressed objects within 1 object stream | |||

| 0 named destinations out of 1000 (max. 500000) | |||

| 6 words of extra memory for PDF output out of 10000 (max. 10000000) | |||

BIN

HomeSolarDataLogger_Two/docs/2.pdf

View File

+ 65

- 0

HomeSolarDataLogger_Two/docs/2.tex

View File

| @ -0,0 +1,65 @@ | |||

| \documentclass[11pt]{article} | |||

| %Gummi|065|=) | |||

| \usepackage{graphicx} | |||

| \usepackage{caption} | |||

| \title{\textbf{Solar Charger Project}} | |||

| \author{Steak Electronics} | |||

| \date{} | |||

| \begin{document} | |||

| \maketitle | |||

| \tableofcontents | |||

| \section{Overview} | |||

| Want to charge a lead battery from a solar panel, and run some load on the battery occasionally. Want to monitor the load, and the charge of the panel. | |||

| \section{Chip Hunting} | |||

| Sorting by cheapest buck boost regulators, I've found a micrel chip, MIC4680, which is a simple buck reg. It can be adjustable, so I will take advantage of that with another slide pot, and use it to charge different battery types. These regs are ~\$2. The next realistic option I see is around 5-6 which are the true buck/boost switching regs. | |||

| Looking at the Mic4680, I want at least 10mA of current passing through to the device downstream, in order to be around 70\% efficient. Looking at the different graphs for output voltage: greatest efficiency is at 12V for low currents. As you lower output voltage, you need more current for equal efficiency. Good for my needs. | |||

| Not sure how I will handle overcurrent. Probably a fuse, or ptc. Too much current will blow the fuse. Don't do that. | |||

| Let's start building the board. | |||

| \subsection{Board considerations} | |||

| Input will be any number of solar cells, in series and or parallel. They will go to the vreg. The vreg will go to the battery, which in turn will have a load, of a micro (probably a nano on sleep mode). But actually, I might want a micro that can operate at up to 14 volts... So a nano might not work. Looks like there is a high voltage PIC and Atmega, but the Atmega is obsolete :/ | |||

| So cheapest is the Pic16. Might try that. It can handle up to 15 volts, which should be safe, with the regulator offering a float voltage (but only a float voltage. Unfortunately, the AVR was up to 18v...) | |||

| Unfortunateyl the PIC is eprom (i.e. UV erasable) only or One time programmed OTP only. Ugh. There is another atmega, which is more expensive, but fully programmable. Let's run with that. | |||

| The atmega406, programs through JTAG on PortB. Page 70 for jtag pinouts. It is a LQFP so a board will be needed, but I don't enjoy breadboarding anyways, (microcontrollers). | |||

| So this chip has an internal regulator, and can run off a wide range of voltages. What is lowest current usage? The data sheet in page 225 mentions the following: | |||

| \begin{itemize} | |||

| \item Active 1.2mA | |||

| \item idle 270uA | |||

| \item ADC Noise Reduction 220 uA | |||

| \item Power-save 35uA | |||

| \item Power-down 20uA | |||

| \item Power-off 1.5uA | |||

| \end{itemize} | |||

| Based on this, I'm thinking we can only run code when necessary and hopefully get somewhere between the 35uA and the 1.2mA with sleep states. | |||

| \textbf{RECAP} | |||

| Solar to vreg to battery, to low power micro with built in vreg with breakouts for pins so I can think of some sensor to attach. Since I do surveillance work, I think a motion sensor would be a good start. We will want to have something switch on and off a low power motion sensor. https://www.futurlec.com/PIR\_Sensors.shtml has a low power pir (relatively cheap) sensor. 50uA. That might be someplace to start. Though I know that these sensors need an external light sensor, or software magic to avoid false alarms. Breakouts for Vcc, Gnd. Breakouts for all pins. Slide pot for vreg (to use other batteries). Fuse to limit current. Switch on shutdown of vreg, for manual shutdown of power. | |||

| \includegraphics[scale=0.5]{../pics/solarlogger_plan.jpg} | |||

| \captionof{figure}{Solar Logger outline. Self sufficient sensors} | |||

| \vspace{0.2in} | |||

| Note that I will also have the capability to log this with the battery station. Which I will do in house. I think that is enough. I don't want to worry too much about the PIR. Anything else I'm forgetting...? | |||

| The connectors I used on the battery station that had a perfect fit for my standard two pin blue screw terminals was the following: | |||

| \begin{verbatim} | |||

| Connectors_Molex:Molex_MiniFit-JR-5556-02A_2x01x4.20mm_Straight | |||

| \end{verbatim} | |||

| I will want to use that again for a few places. | |||

| \end{document} | |||

+ 37

- 0

HomeSolarDataLogger_Two/docs/2.tex~

View File

| @ -0,0 +1,37 @@ | |||

| \documentclass[11pt]{article} | |||

| %Gummi|065|=) | |||

| \usepackage{graphicx} | |||

| \usepackage{caption} | |||

| \title{\textbf{Solar Charger Project}} | |||

| \author{Steak Electronics} | |||

| \date{} | |||

| \begin{document} | |||

| \maketitle | |||

| \tableofcontents | |||

| \section{Overview} | |||

| Want to charge a lead battery from a solar panel, and run some load on the battery occasionally. Want to monitor the load, and the charge of the panel. | |||

| \section{Chip Hunting} | |||

| Sorting by cheapest buck boost regulators, I've found a micrel chip, MIC4680, which is a simple buck reg. It can be adjustable, so I will take advantage of that with another slide pot, and use it to charge different battery types. These regs are ~\$2. The next realistic option I see is around 5-6 which are the true buck/boost switching regs. | |||

| Not sure how I will handle overcurrent. Probably a fuse, or ptc. Too much current will blow the fuse. Don't do that. | |||

| Let's start building the board. | |||

| \subsection{Board considerations} | |||

| Input will be any number of solar cells, in series and or parallel. They will go to the vreg. The vreg will go to the battery, which in turn will have a load, of a micro (probably a nano on sleep mode). But actually, I might want a micro that can operate at up to 14 volts... So a nano might not work. Looks like there is a high voltage PIC and Atmega, but the Atmega is obsolete :/ | |||

| So cheapest is the Pic16. Might try that. It can handle up to 15 volts, which should be safe, with the regulator offering a float voltage (but only a float voltage. Unfortunately, the AVR was up to 18v...) | |||

| Unfortunateyl the PIC is eprom (i.e. UV erasable) only or One time programmed OTP only. Ugh. | |||

| \end{document} | |||

+ 3

- 0

HomeSolarDataLogger_Two/docs/2.toc

View File

| @ -0,0 +1,3 @@ | |||

| \contentsline {section}{\numberline {1}Overview}{1} | |||

| \contentsline {section}{\numberline {2}Chip Hunting}{1} | |||

| \contentsline {subsection}{\numberline {2.1}Board considerations}{2} | |||

+ 345

- 0

HomeSolarDataLogger_Two/pcb/MIC4680_VREG.bak

View File

| @ -0,0 +1,345 @@ | |||

| EESchema Schematic File Version 4 | |||

| EELAYER 26 0 | |||

| EELAYER END | |||

| $Descr A4 11693 8268 | |||

| encoding utf-8 | |||

| Sheet 2 2 | |||

| Title "" | |||

| Date "" | |||

| Rev "" | |||

| Comp "" | |||

| Comment1 "" | |||

| Comment2 "" | |||

| Comment3 "" | |||

| Comment4 "" | |||

| $EndDescr | |||

| $Comp | |||

| L regul:MIC4690 U2 | |||

| U 1 1 5CC7C5FB | |||

| P 5400 2950 | |||

| F 0 "U2" H 5400 3365 50 0000 C CNN | |||

| F 1 "MIC4690" H 5400 3274 50 0000 C CNN | |||

| F 2 "" H 5400 2950 50 0001 C CNN | |||

| F 3 "" H 5400 2950 50 0000 C CNN | |||

| 1 5400 2950 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| $Comp | |||

| L power:GND #PWR0101 | |||

| U 1 1 5CC7C7C7 | |||

| P 5250 3450 | |||

| F 0 "#PWR0101" H 5250 3200 50 0001 C CNN | |||

| F 1 "GND" H 5255 3277 50 0000 C CNN | |||

| F 2 "" H 5250 3450 50 0000 C CNN | |||

| F 3 "" H 5250 3450 50 0000 C CNN | |||

| 1 5250 3450 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| $Comp | |||

| L device:C_Small C1 | |||

| U 1 1 5CC7C891 | |||

| P 4550 2900 | |||

| F 0 "C1" H 4642 2946 50 0000 L CNN | |||

| F 1 "15uf" H 4642 2855 50 0000 L CNN | |||

| F 2 "Capacitors_THT:C_Radial_D8_L13_P3.8" H 4642 2809 50 0001 L CNN | |||

| F 3 "" H 4550 2900 50 0000 C CNN | |||

| 1 4550 2900 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| Wire Wire Line | |||

| 6050 2800 6050 3150 | |||

| $Comp | |||

| L device:D_Schottky D1 | |||

| U 1 1 5CC7CC1D | |||

| P 6050 3300 | |||

| F 0 "D1" V 6004 3379 50 0000 L CNN | |||

| F 1 "SS26" V 6095 3379 50 0000 L CNN | |||

| F 2 "" H 6050 3300 50 0001 C CNN | |||

| F 3 "" H 6050 3300 50 0000 C CNN | |||

| 1 6050 3300 | |||

| 0 1 1 0 | |||

| $EndComp | |||

| Connection ~ 5250 3450 | |||

| Wire Wire Line | |||

| 5250 3450 5350 3450 | |||

| Wire Wire Line | |||

| 5550 3400 5550 3450 | |||

| Connection ~ 5550 3450 | |||

| Wire Wire Line | |||

| 5550 3450 6050 3450 | |||

| Wire Wire Line | |||

| 5450 3400 5450 3450 | |||

| Connection ~ 5450 3450 | |||

| Wire Wire Line | |||

| 5450 3450 5550 3450 | |||

| Wire Wire Line | |||

| 5350 3400 5350 3450 | |||

| Connection ~ 5350 3450 | |||

| Wire Wire Line | |||

| 5350 3450 5450 3450 | |||

| Wire Wire Line | |||

| 5250 3400 5250 3450 | |||

| $Comp | |||

| L pspice:INDUCTOR L1 | |||

| U 1 1 5CC7D12F | |||

| P 6400 2800 | |||

| F 0 "L1" H 6400 3015 50 0000 C CNN | |||

| F 1 "68uH" H 6400 2924 50 0000 C CNN | |||

| F 2 "" H 6400 2800 50 0001 C CNN | |||

| F 3 "" H 6400 2800 50 0000 C CNN | |||

| 1 6400 2800 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| Wire Wire Line | |||

| 6150 2800 6050 2800 | |||

| Connection ~ 6150 2800 | |||

| Wire Wire Line | |||

| 6650 2800 6700 2800 | |||

| $Comp | |||

| L device:C_Small C2 | |||

| U 1 1 5CC7D6A0 | |||

| P 7050 2900 | |||

| F 0 "C2" H 7142 2946 50 0000 L CNN | |||

| F 1 "220uf" H 7142 2855 50 0000 L CNN | |||

| F 2 "Capacitors_THT:C_Radial_D8_L13_P3.8" H 7050 2900 50 0001 C CNN | |||

| F 3 "" H 7050 2900 50 0000 C CNN | |||

| 1 7050 2900 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| Wire Wire Line | |||

| 7050 3000 7050 3450 | |||

| Connection ~ 6050 3450 | |||

| Wire Wire Line | |||

| 4550 3450 4550 3000 | |||

| Wire Wire Line | |||

| 4550 3450 5250 3450 | |||

| Wire Wire Line | |||

| 4550 2800 4650 2800 | |||

| Wire Wire Line | |||

| 4650 3100 4350 3100 | |||

| $Comp | |||

| L switches:SW_Push_SPDT SW1 | |||

| U 1 1 5CC7E078 | |||

| P 4150 3100 | |||

| F 0 "SW1" H 4800 3350 50 0000 C CNN | |||

| F 1 "SW_SPDT" H 4700 3200 50 0000 C CNN | |||

| F 2 "" H 4150 3100 50 0001 C CNN | |||

| F 3 "" H 4150 3100 50 0000 C CNN | |||

| 1 4150 3100 | |||

| -1 0 0 1 | |||

| $EndComp | |||

| $Comp | |||

| L device:R R2 | |||

| U 1 1 5CC7E1A3 | |||

| P 3950 3350 | |||

| F 0 "R2" H 4020 3396 50 0000 L CNN | |||

| F 1 "1K" H 4020 3305 50 0000 L CNN | |||

| F 2 "Capacitors_SMD:C_0805_HandSoldering" V 3880 3350 50 0001 C CNN | |||

| F 3 "" H 3950 3350 50 0000 C CNN | |||

| 1 3950 3350 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| $Comp | |||

| L power:GND #PWR0102 | |||

| U 1 1 5CC7E251 | |||

| P 3950 3500 | |||

| F 0 "#PWR0102" H 3950 3250 50 0001 C CNN | |||

| F 1 "GND" H 3955 3327 50 0000 C CNN | |||

| F 2 "" H 3950 3500 50 0000 C CNN | |||

| F 3 "" H 3950 3500 50 0000 C CNN | |||

| 1 3950 3500 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| $Comp | |||

| L device:R R1 | |||

| U 1 1 5CC7E382 | |||

| P 3700 2850 | |||

| F 0 "R1" H 3770 2896 50 0000 L CNN | |||

| F 1 "1K" H 3770 2805 50 0000 L CNN | |||

| F 2 "Capacitors_SMD:C_0805_HandSoldering" V 3630 2850 50 0001 C CNN | |||

| F 3 "" H 3700 2850 50 0000 C CNN | |||

| 1 3700 2850 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| Wire Wire Line | |||

| 3950 3000 3700 3000 | |||

| Text Label 4550 2800 0 50 ~ 0 | |||

| Vin | |||

| Text Label 3700 2700 0 50 ~ 0 | |||

| Vin | |||

| $Comp | |||

| L device:R R4 | |||

| U 1 1 5CC7EECB | |||

| P 6700 2950 | |||

| F 0 "R4" H 6770 2996 50 0000 L CNN | |||

| F 1 "5900" H 6770 2905 50 0000 L CNN | |||

| F 2 "Capacitors_SMD:C_0805_HandSoldering" V 6630 2950 50 0001 C CNN | |||

| F 3 "" H 6700 2950 50 0000 C CNN | |||

| 1 6700 2950 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| Connection ~ 6700 2800 | |||

| Wire Wire Line | |||

| 6700 2800 7050 2800 | |||

| Wire Wire Line | |||

| 6700 3150 6700 3100 | |||

| Wire Wire Line | |||

| 6700 3100 6150 3100 | |||

| Connection ~ 6700 3100 | |||

| $Comp | |||

| L device:POT RV1 | |||

| U 1 1 5CC7F60F | |||

| P 6400 4200 | |||

| F 0 "RV1" H 6330 4246 50 0000 R CNN | |||

| F 1 "100K" H 6330 4155 50 0000 R CNN | |||

| F 2 "" H 6400 4200 50 0001 C CNN | |||

| F 3 "" H 6400 4200 50 0000 C CNN | |||

| 1 6400 4200 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| $Comp | |||

| L device:R R3 | |||

| U 1 1 5CC7FB5A | |||

| P 6400 3900 | |||

| F 0 "R3" H 6470 3946 50 0000 L CNN | |||

| F 1 "583" H 6470 3855 50 0000 L CNN | |||

| F 2 "Capacitors_SMD:C_0805_HandSoldering" V 6330 3900 50 0001 C CNN | |||

| F 3 "" H 6400 3900 50 0000 C CNN | |||

| 1 6400 3900 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| Text Label 6700 3150 0 50 ~ 0 | |||

| VDIV+ | |||

| Text Label 6700 3450 0 50 ~ 0 | |||

| VDIV- | |||

| Text Label 6400 3750 0 50 ~ 0 | |||

| VDIV+ | |||

| Text Label 6400 4350 0 50 ~ 0 | |||

| VDIV- | |||

| Wire Wire Line | |||

| 7050 2800 7650 2800 | |||

| Wire Wire Line | |||

| 6050 3450 7050 3450 | |||

| Connection ~ 7050 2800 | |||

| $Comp | |||

| L power:VCC #PWR0103 | |||

| U 1 1 5CC801A5 | |||

| P 7950 2800 | |||

| F 0 "#PWR0103" H 7950 2650 50 0001 C CNN | |||

| F 1 "VCC" H 7967 2973 50 0000 C CNN | |||

| F 2 "" H 7950 2800 50 0000 C CNN | |||

| F 3 "" H 7950 2800 50 0000 C CNN | |||

| 1 7950 2800 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| Wire Wire Line | |||

| 4550 2800 4250 2800 | |||

| Wire Wire Line | |||

| 4250 2800 4250 2450 | |||

| Connection ~ 4550 2800 | |||

| $Comp | |||

| L conn:CONN_01X05 P2 | |||

| U 1 1 5CC806DA | |||

| P 4050 2250 | |||

| F 0 "P2" V 4015 1962 50 0000 R CNN | |||

| F 1 "SolarV+InBreakout1inch" V 3924 1962 50 0000 R CNN | |||

| F 2 "Pin_Headers:Pin_Header_Straight_1x05" H 4050 2250 50 0001 C CNN | |||

| F 3 "" H 4050 2250 50 0000 C CNN | |||

| 1 4050 2250 | |||

| 0 -1 -1 0 | |||

| $EndComp | |||

| Wire Wire Line | |||

| 4250 2450 4150 2450 | |||

| Connection ~ 4250 2450 | |||

| Connection ~ 3950 2450 | |||

| Wire Wire Line | |||

| 3950 2450 3850 2450 | |||

| Connection ~ 4050 2450 | |||

| Wire Wire Line | |||

| 4050 2450 3950 2450 | |||

| Connection ~ 4150 2450 | |||

| Wire Wire Line | |||

| 4150 2450 4050 2450 | |||

| $Comp | |||

| L conn:CONN_01X05 P3 | |||

| U 1 1 5CC80DB7 | |||

| P 7250 3650 | |||

| F 0 "P3" V 7122 3928 50 0000 L CNN | |||

| F 1 "GND_BRKOUT1inch" V 7213 3928 50 0000 L CNN | |||

| F 2 "Pin_Headers:Pin_Header_Straight_1x05" H 7250 3650 50 0001 C CNN | |||

| F 3 "" H 7250 3650 50 0000 C CNN | |||

| 1 7250 3650 | |||

| 0 1 1 0 | |||

| $EndComp | |||

| Connection ~ 7050 3450 | |||

| Wire Wire Line | |||

| 7050 3450 7150 3450 | |||

| Connection ~ 7150 3450 | |||

| Wire Wire Line | |||

| 7150 3450 7250 3450 | |||

| Connection ~ 7250 3450 | |||

| Wire Wire Line | |||

| 7250 3450 7350 3450 | |||

| Connection ~ 7350 3450 | |||

| Wire Wire Line | |||

| 7350 3450 7450 3450 | |||

| $Comp | |||

| L device:Fuse F1 | |||

| U 1 1 5CC81708 | |||

| P 7800 2800 | |||

| F 0 "F1" V 7603 2800 50 0000 C CNN | |||

| F 1 "Fuse" V 7694 2800 50 0000 C CNN | |||

| F 2 "Fuse_Holders_and_Fuses:Fuseholder5x20_horiz_SemiClosed_Casing10x25mm" V 7730 2800 50 0001 C CNN | |||

| F 3 "" H 7800 2800 50 0000 C CNN | |||

| 1 7800 2800 | |||

| 0 1 1 0 | |||

| $EndComp | |||

| Text Notes 5450 2150 0 50 ~ 0 | |||

| I should add in some reverse \nvoltage protection (PMOSfet) | |||

| $Comp | |||

| L conn:CONN_01X04 P4 | |||

| U 1 1 5CC824DA | |||

| P 7700 3250 | |||

| F 0 "P4" V 7665 3012 50 0000 R CNN | |||

| F 1 "GNDScrwTerminal" V 7574 3012 50 0000 R CNN | |||

| F 2 "Connectors_Molex:Molex_MiniFit-JR-5556-08A_2x04x4.20mm_Straight" H 7700 3250 50 0001 C CNN | |||

| F 3 "" H 7700 3250 50 0000 C CNN | |||

| 1 7700 3250 | |||

| 0 -1 -1 0 | |||

| $EndComp | |||

| $Comp | |||

| L conn:CONN_01X04 P1 | |||

| U 1 1 5CC825E0 | |||

| P 3500 2250 | |||

| F 0 "P1" V 3450 2600 50 0000 R CNN | |||

| F 1 "BAT_ScrwTerminal" V 3350 3050 50 0000 R CNN | |||

| F 2 "Connectors_Molex:Molex_MiniFit-JR-5556-08A_2x04x4.20mm_Straight" H 3500 2250 50 0001 C CNN | |||

| F 3 "" H 3500 2250 50 0000 C CNN | |||

| 1 3500 2250 | |||

| 0 -1 -1 0 | |||

| $EndComp | |||

| Wire Wire Line | |||

| 3350 2450 3450 2450 | |||

| Connection ~ 3850 2450 | |||

| Connection ~ 3450 2450 | |||

| Wire Wire Line | |||

| 3450 2450 3550 2450 | |||

| Connection ~ 3550 2450 | |||

| Wire Wire Line | |||

| 3550 2450 3650 2450 | |||

| Connection ~ 3650 2450 | |||

| Wire Wire Line | |||

| 3650 2450 3850 2450 | |||

| Wire Wire Line | |||

| 7450 3450 7550 3450 | |||

| Connection ~ 7450 3450 | |||

| Connection ~ 7550 3450 | |||

| Wire Wire Line | |||

| 7550 3450 7650 3450 | |||

| Connection ~ 7650 3450 | |||

| Wire Wire Line | |||

| 7650 3450 7750 3450 | |||

| Connection ~ 7750 3450 | |||

| Wire Wire Line | |||

| 7750 3450 7850 3450 | |||

| $EndSCHEMATC | |||

+ 345

- 0

HomeSolarDataLogger_Two/pcb/MIC4680_VREG.sch

View File

| @ -0,0 +1,345 @@ | |||

| EESchema Schematic File Version 4 | |||

| EELAYER 26 0 | |||

| EELAYER END | |||

| $Descr A4 11693 8268 | |||

| encoding utf-8 | |||

| Sheet 2 2 | |||

| Title "" | |||

| Date "" | |||

| Rev "" | |||

| Comp "" | |||

| Comment1 "" | |||

| Comment2 "" | |||

| Comment3 "" | |||

| Comment4 "" | |||

| $EndDescr | |||

| $Comp | |||

| L regul:MIC4690 U2 | |||

| U 1 1 5CC7C5FB | |||

| P 5400 2950 | |||

| F 0 "U2" H 5400 3365 50 0000 C CNN | |||

| F 1 "MIC4690" H 5400 3274 50 0000 C CNN | |||

| F 2 "" H 5400 2950 50 0001 C CNN | |||

| F 3 "" H 5400 2950 50 0000 C CNN | |||

| 1 5400 2950 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| $Comp | |||

| L power:GND #PWR0101 | |||

| U 1 1 5CC7C7C7 | |||

| P 5250 3450 | |||

| F 0 "#PWR0101" H 5250 3200 50 0001 C CNN | |||

| F 1 "GND" H 5255 3277 50 0000 C CNN | |||

| F 2 "" H 5250 3450 50 0000 C CNN | |||

| F 3 "" H 5250 3450 50 0000 C CNN | |||

| 1 5250 3450 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| $Comp | |||

| L device:C_Small C1 | |||

| U 1 1 5CC7C891 | |||

| P 4550 2900 | |||

| F 0 "C1" H 4642 2946 50 0000 L CNN | |||

| F 1 "15uf" H 4642 2855 50 0000 L CNN | |||

| F 2 "Capacitors_THT:C_Radial_D8_L13_P3.8" H 4642 2809 50 0001 L CNN | |||

| F 3 "" H 4550 2900 50 0000 C CNN | |||

| 1 4550 2900 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| Wire Wire Line | |||

| 6050 2800 6050 3150 | |||

| $Comp | |||

| L device:D_Schottky D1 | |||

| U 1 1 5CC7CC1D | |||

| P 6050 3300 | |||

| F 0 "D1" V 6004 3379 50 0000 L CNN | |||

| F 1 "SS26" V 6095 3379 50 0000 L CNN | |||

| F 2 "" H 6050 3300 50 0001 C CNN | |||

| F 3 "" H 6050 3300 50 0000 C CNN | |||

| 1 6050 3300 | |||

| 0 1 1 0 | |||

| $EndComp | |||

| Connection ~ 5250 3450 | |||

| Wire Wire Line | |||

| 5250 3450 5350 3450 | |||

| Wire Wire Line | |||

| 5550 3400 5550 3450 | |||

| Connection ~ 5550 3450 | |||

| Wire Wire Line | |||

| 5550 3450 6050 3450 | |||

| Wire Wire Line | |||

| 5450 3400 5450 3450 | |||

| Connection ~ 5450 3450 | |||

| Wire Wire Line | |||

| 5450 3450 5550 3450 | |||

| Wire Wire Line | |||

| 5350 3400 5350 3450 | |||

| Connection ~ 5350 3450 | |||

| Wire Wire Line | |||

| 5350 3450 5450 3450 | |||

| Wire Wire Line | |||

| 5250 3400 5250 3450 | |||

| $Comp | |||

| L pspice:INDUCTOR L1 | |||

| U 1 1 5CC7D12F | |||

| P 6400 2800 | |||

| F 0 "L1" H 6400 3015 50 0000 C CNN | |||

| F 1 "68uH" H 6400 2924 50 0000 C CNN | |||

| F 2 "" H 6400 2800 50 0001 C CNN | |||

| F 3 "" H 6400 2800 50 0000 C CNN | |||

| 1 6400 2800 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| Wire Wire Line | |||

| 6150 2800 6050 2800 | |||

| Connection ~ 6150 2800 | |||

| Wire Wire Line | |||

| 6650 2800 6700 2800 | |||

| $Comp | |||

| L device:C_Small C2 | |||

| U 1 1 5CC7D6A0 | |||

| P 7050 2900 | |||

| F 0 "C2" H 7142 2946 50 0000 L CNN | |||

| F 1 "220uf" H 7142 2855 50 0000 L CNN | |||

| F 2 "Capacitors_THT:C_Radial_D8_L13_P3.8" H 7050 2900 50 0001 C CNN | |||

| F 3 "" H 7050 2900 50 0000 C CNN | |||

| 1 7050 2900 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| Wire Wire Line | |||

| 7050 3000 7050 3450 | |||

| Connection ~ 6050 3450 | |||

| Wire Wire Line | |||

| 4550 3450 4550 3000 | |||

| Wire Wire Line | |||

| 4550 3450 5250 3450 | |||

| Wire Wire Line | |||

| 4550 2800 4650 2800 | |||

| Wire Wire Line | |||

| 4650 3100 4350 3100 | |||

| $Comp | |||

| L switches:SW_Push_SPDT SW1 | |||

| U 1 1 5CC7E078 | |||

| P 4150 3100 | |||

| F 0 "SW1" H 4800 3350 50 0000 C CNN | |||

| F 1 "SW_SPDT" H 4700 3200 50 0000 C CNN | |||

| F 2 "" H 4150 3100 50 0001 C CNN | |||

| F 3 "" H 4150 3100 50 0000 C CNN | |||

| 1 4150 3100 | |||

| -1 0 0 1 | |||

| $EndComp | |||

| $Comp | |||

| L device:R R2 | |||

| U 1 1 5CC7E1A3 | |||

| P 3950 3350 | |||

| F 0 "R2" H 4020 3396 50 0000 L CNN | |||

| F 1 "1K" H 4020 3305 50 0000 L CNN | |||

| F 2 "Capacitors_SMD:C_0805_HandSoldering" V 3880 3350 50 0001 C CNN | |||

| F 3 "" H 3950 3350 50 0000 C CNN | |||

| 1 3950 3350 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| $Comp | |||

| L power:GND #PWR0102 | |||

| U 1 1 5CC7E251 | |||

| P 3950 3500 | |||

| F 0 "#PWR0102" H 3950 3250 50 0001 C CNN | |||

| F 1 "GND" H 3955 3327 50 0000 C CNN | |||

| F 2 "" H 3950 3500 50 0000 C CNN | |||

| F 3 "" H 3950 3500 50 0000 C CNN | |||

| 1 3950 3500 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| $Comp | |||

| L device:R R1 | |||

| U 1 1 5CC7E382 | |||

| P 3700 2850 | |||

| F 0 "R1" H 3770 2896 50 0000 L CNN | |||

| F 1 "1K" H 3770 2805 50 0000 L CNN | |||

| F 2 "Capacitors_SMD:C_0805_HandSoldering" V 3630 2850 50 0001 C CNN | |||

| F 3 "" H 3700 2850 50 0000 C CNN | |||

| 1 3700 2850 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| Wire Wire Line | |||

| 3950 3000 3700 3000 | |||

| Text Label 4550 2800 0 50 ~ 0 | |||

| Vin | |||

| Text Label 3700 2700 0 50 ~ 0 | |||

| Vin | |||

| $Comp | |||

| L device:R R4 | |||

| U 1 1 5CC7EECB | |||

| P 6700 2950 | |||

| F 0 "R4" H 6770 2996 50 0000 L CNN | |||

| F 1 "5900" H 6770 2905 50 0000 L CNN | |||

| F 2 "Capacitors_SMD:C_0805_HandSoldering" V 6630 2950 50 0001 C CNN | |||

| F 3 "" H 6700 2950 50 0000 C CNN | |||

| 1 6700 2950 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| Connection ~ 6700 2800 | |||

| Wire Wire Line | |||

| 6700 2800 7050 2800 | |||

| Wire Wire Line | |||

| 6700 3150 6700 3100 | |||

| Wire Wire Line | |||

| 6700 3100 6150 3100 | |||

| Connection ~ 6700 3100 | |||

| $Comp | |||

| L device:POT RV1 | |||

| U 1 1 5CC7F60F | |||

| P 6400 4200 | |||

| F 0 "RV1" H 6330 4246 50 0000 R CNN | |||

| F 1 "100K" H 6330 4155 50 0000 R CNN | |||

| F 2 "" H 6400 4200 50 0001 C CNN | |||

| F 3 "" H 6400 4200 50 0000 C CNN | |||

| 1 6400 4200 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| $Comp | |||

| L device:R R3 | |||

| U 1 1 5CC7FB5A | |||

| P 6400 3900 | |||

| F 0 "R3" H 6470 3946 50 0000 L CNN | |||

| F 1 "583" H 6470 3855 50 0000 L CNN | |||

| F 2 "Capacitors_SMD:C_0805_HandSoldering" V 6330 3900 50 0001 C CNN | |||

| F 3 "" H 6400 3900 50 0000 C CNN | |||

| 1 6400 3900 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| Text Label 6700 3150 0 50 ~ 0 | |||

| VDIV+ | |||

| Text Label 6700 3450 0 50 ~ 0 | |||

| VDIV- | |||

| Text Label 6400 3750 0 50 ~ 0 | |||

| VDIV+ | |||

| Text Label 6400 4350 0 50 ~ 0 | |||

| VDIV- | |||

| Wire Wire Line | |||

| 7050 2800 7650 2800 | |||

| Wire Wire Line | |||

| 6050 3450 7050 3450 | |||

| Connection ~ 7050 2800 | |||

| $Comp | |||

| L power:VCC #PWR0103 | |||

| U 1 1 5CC801A5 | |||

| P 7950 2800 | |||

| F 0 "#PWR0103" H 7950 2650 50 0001 C CNN | |||

| F 1 "VCC" H 7967 2973 50 0000 C CNN | |||

| F 2 "" H 7950 2800 50 0000 C CNN | |||

| F 3 "" H 7950 2800 50 0000 C CNN | |||

| 1 7950 2800 | |||

| 1 0 0 -1 | |||

| $EndComp | |||

| Wire Wire Line | |||

| 4550 2800 4250 2800 | |||

| Wire Wire Line | |||

| 4250 2800 4250 2450 | |||

| Connection ~ 4550 2800 | |||

| $Comp | |||

| L conn:CONN_01X05 P2 | |||

| U 1 1 5CC806DA | |||

| P 4050 2250 | |||

| F 0 "P2" V 4015 1962 50 0000 R CNN | |||

| F 1 "SolarV+InBreakout1inch" V 3924 1962 50 0000 R CNN | |||

| F 2 "Pin_Headers:Pin_Header_Straight_1x05" H 4050 2250 50 0001 C CNN | |||

| F 3 "" H 4050 2250 50 0000 C CNN | |||

| 1 4050 2250 | |||

| 0 -1 -1 0 | |||

| $EndComp | |||

| Wire Wire Line | |||

| 4250 2450 4150 2450 | |||

| Connection ~ 4250 2450 | |||

| Connection ~ 3950 2450 | |||

| Wire Wire Line | |||

| 3950 2450 3850 2450 | |||

| Connection ~ 4050 2450 | |||

| Wire Wire Line | |||

| 4050 2450 3950 2450 | |||

| Connection ~ 4150 2450 | |||

| Wire Wire Line | |||

| 4150 2450 4050 2450 | |||

| $Comp | |||

| L conn:CONN_01X05 P3 | |||

| U 1 1 5CC80DB7 | |||

| P 7250 3650 | |||

| F 0 "P3" V 7122 3928 50 0000 L CNN | |||

| F 1 "GND_BRKOUT1inch" V 7213 3928 50 0000 L CNN | |||

| F 2 "Pin_Headers:Pin_Header_Straight_1x05" H 7250 3650 50 0001 C CNN | |||

| F 3 "" H 7250 3650 50 0000 C CNN | |||

| 1 7250 3650 | |||

| 0 1 1 0 | |||

| $EndComp | |||

| Connection ~ 7050 3450 | |||

| Wire Wire Line | |||

| 7050 3450 7150 3450 | |||

| Connection ~ 7150 3450 | |||

| Wire Wire Line | |||

| 7150 3450 7250 3450 | |||

| Connection ~ 7250 3450 | |||

| Wire Wire Line | |||

| 7250 3450 7350 3450 | |||

| Connection ~ 7350 3450 | |||

| Wire Wire Line | |||

| 7350 3450 7450 3450 | |||

| $Comp | |||

| L device:Fuse F1 | |||

| U 1 1 5CC81708 | |||

| P 7800 2800 | |||

| F 0 "F1" V 7603 2800 50 0000 C CNN | |||

| F 1 "Fuse" V 7694 2800 50 0000 C CNN | |||

| F 2 "Fuse_Holders_and_Fuses:Fuseholder5x20_horiz_SemiClosed_Casing10x25mm" V 7730 2800 50 0001 C CNN | |||

| F 3 "" H 7800 2800 50 0000 C CNN | |||

| 1 7800 2800 | |||

| 0 1 1 0 | |||

| $EndComp | |||

| Text Notes 5450 2150 0 50 ~ 0 | |||

| I should add in some reverse \nvoltage protection (PMOSfet) | |||

| $Comp | |||

| L conn:CONN_01X04 P4 | |||

| U 1 1 5CC824DA | |||

| P 7700 3250 | |||

| F 0 "P4" V 7665 3012 50 0000 R CNN | |||

| F 1 "GNDScrwTerminal" V 7574 3012 50 0000 R CNN | |||

| F 2 "Connectors_Molex:Molex_MiniFit-JR-5556-08A_2x04x4.20mm_Straight" H 7700 3250 50 0001 C CNN | |||

| F 3 "" H 7700 3250 50 0000 C CNN | |||

| 1 7700 3250 | |||

| 0 -1 -1 0 | |||

| $EndComp | |||

| $Comp | |||

| L conn:CONN_01X04 P1 | |||

| U 1 1 5CC825E0 | |||

| P 3500 2250 | |||

| F 0 "P1" V 3450 2600 50 0000 R CNN | |||

| F 1 "BAT_ScrwTerminal" V 3350 3050 50 0000 R CNN | |||

| F 2 "Connectors_Molex:Molex_MiniFit-JR-5556-08A_2x04x4.20mm_Straight" H 3500 2250 50 0001 C CNN | |||

| F 3 "" H 3500 2250 50 0000 C CNN | |||

| 1 3500 2250 | |||

| 0 -1 -1 0 | |||

| $EndComp | |||

| Wire Wire Line | |||

| 3350 2450 3450 2450 | |||

| Connection ~ 3850 2450 | |||

| Connection ~ 3450 2450 | |||

| Wire Wire Line | |||

| 3450 2450 3550 2450 | |||

| Connection ~ 3550 2450 | |||

| Wire Wire Line | |||

| 3550 2450 3650 2450 | |||

| Connection ~ 3650 2450 | |||

| Wire Wire Line | |||

| 3650 2450 3850 2450 | |||

| Wire Wire Line | |||

| 7450 3450 7550 3450 | |||

| Connection ~ 7450 3450 | |||

| Connection ~ 7550 3450 | |||

| Wire Wire Line | |||

| 7550 3450 7650 3450 | |||

| Connection ~ 7650 3450 | |||

| Wire Wire Line | |||

| 7650 3450 7750 3450 | |||

| Connection ~ 7750 3450 | |||

| Wire Wire Line | |||

| 7750 3450 7850 3450 | |||

| $EndSCHEMATC | |||

+ 303

- 0

HomeSolarDataLogger_Two/pcb/homesolar2-cache.lib

View File

| @ -0,0 +1,303 @@ | |||

| EESchema-LIBRARY Version 2.4 | |||

| #encoding utf-8 | |||

| # | |||

| # MCU_Microchip_ATmega:ATmega406-1AA | |||

| # | |||

| DEF MCU_Microchip_ATmega:ATmega406-1AA U 0 20 Y Y 1 F N | |||

| F0 "U" -500 1750 50 H V L BNN | |||

| F1 "MCU_Microchip_ATmega:ATmega406-1AA" 100 -1750 50 H V L TNN | |||

| F2 "Package_QFP:LQFP-48_7x7mm_P0.5mm" 0 0 50 H I C CIN | |||

| F3 "" 0 0 50 H I C CNN | |||

| $FPLIST | |||

| LQFP*7x7mm*P0.5mm* | |||

| $ENDFPLIST | |||

| DRAW | |||

| S -500 1700 500 -1700 1 1 10 f | |||

| X SGND 1 -100 -1800 100 U 50 50 1 1 W | |||

| X PA5 10 -600 -1400 100 R 50 50 1 1 T | |||

| X PA6 11 -600 -1500 100 R 50 50 1 1 T | |||

| X PA7 12 -600 -1600 100 R 50 50 1 1 T | |||

| X ~RESET 13 -600 1100 100 R 50 50 1 1 I | |||

| X XTAL1 14 -600 900 100 R 50 50 1 1 I | |||

| X XTAL2 15 -600 700 100 R 50 50 1 1 O | |||

| X GND 16 0 -1800 100 U 50 50 1 1 P N | |||

| X PB0 17 -600 0 100 R 50 50 1 1 T | |||

| X PB1 18 -600 -100 100 R 50 50 1 1 T | |||

| X PB2 19 -600 -200 100 R 50 50 1 1 T | |||

| X PA0 2 -600 -900 100 R 50 50 1 1 T | |||

| X PB3 20 -600 -300 100 R 50 50 1 1 T | |||

| X PB4 21 -600 -400 100 R 50 50 1 1 T | |||

| X PB5 22 -600 -500 100 R 50 50 1 1 T | |||

| X SCL 23 -600 1400 100 R 50 50 1 1 I | |||

| X SDA 24 -600 1300 100 R 50 50 1 1 B | |||

| X PB6 25 -600 -600 100 R 50 50 1 1 T | |||

| X PB7 26 -600 -700 100 R 50 50 1 1 T | |||

| X PD0 27 -600 500 100 R 50 50 1 1 T | |||

| X PD1 28 -600 400 100 R 50 50 1 1 T | |||

| X GND 29 0 -1800 100 U 50 50 1 1 P N | |||

| X PA1 3 -600 -1000 100 R 50 50 1 1 T | |||

| X PC0 30 -600 200 100 R 50 50 1 1 C | |||

| X BATT 31 -600 1600 100 R 50 50 1 1 I | |||

| X OPC 32 600 1500 100 L 50 50 1 1 O | |||

| X OC 33 600 1600 100 L 50 50 1 1 O | |||

| X VFET 34 100 1800 100 D 50 50 1 1 W | |||

| X OD 35 600 1400 100 L 50 50 1 1 O | |||

| X PVT 36 600 1200 100 L 50 50 1 1 I | |||

| X GND 37 0 -1800 100 U 50 50 1 1 P N | |||

| X PV4 38 600 1000 100 L 50 50 1 1 I | |||

| X PV3 39 600 800 100 L 50 50 1 1 I | |||

| X PA2 4 -600 -1100 100 R 50 50 1 1 T | |||

| X PV2 40 600 600 100 L 50 50 1 1 I | |||

| X PV1 41 600 400 100 L 50 50 1 1 I | |||

| X NV 42 600 200 100 L 50 50 1 1 I | |||

| X VREF 43 600 -1200 100 L 50 50 1 1 P | |||

| X VREFGND 44 600 -1400 100 L 50 50 1 1 P | |||

| X PPI 45 600 -200 100 L 50 50 1 1 I | |||

| X PI 46 600 -400 100 L 50 50 1 1 I | |||

| X NI 47 600 -700 100 L 50 50 1 1 I | |||

| X NNI 48 600 -900 100 L 50 50 1 1 I | |||

| X PA3 5 -600 -1200 100 R 50 50 1 1 T | |||

| X VREG 6 600 -1600 100 L 50 50 1 1 w | |||

| X VCC 7 0 1800 100 D 50 50 1 1 W | |||

| X GND 8 0 -1800 100 U 50 50 1 1 W | |||

| X PA4 9 -600 -1300 100 R 50 50 1 1 T | |||

| ENDDRAW | |||

| ENDDEF | |||

| # | |||

| # conn:CONN_01X04 | |||

| # | |||

| DEF conn:CONN_01X04 P 0 40 Y N 1 F N | |||

| F0 "P" 0 250 50 H V C CNN | |||

| F1 "conn:CONN_01X04" 100 0 50 V V C CNN | |||

| F2 "" 0 0 50 H V C CNN | |||

| F3 "" 0 0 50 H V C CNN | |||

| $FPLIST | |||

| Pin_Header_Straight_1X04 | |||

| Pin_Header_Angled_1X04 | |||

| Socket_Strip_Straight_1X04 | |||

| Socket_Strip_Angled_1X04 | |||

| $ENDFPLIST | |||

| DRAW | |||

| S -50 -145 10 -155 0 1 0 N | |||

| S -50 -45 10 -55 0 1 0 N | |||

| S -50 55 10 45 0 1 0 N | |||

| S -50 155 10 145 0 1 0 N | |||

| S -50 200 50 -200 0 1 0 N | |||

| X P1 1 -200 150 150 R 50 50 1 1 P | |||

| X P2 2 -200 50 150 R 50 50 1 1 P | |||

| X P3 3 -200 -50 150 R 50 50 1 1 P | |||

| X P4 4 -200 -150 150 R 50 50 1 1 P | |||

| ENDDRAW | |||

| ENDDEF | |||

| # | |||

| # conn:CONN_01X05 | |||

| # | |||

| DEF conn:CONN_01X05 P 0 40 Y N 1 F N | |||

| F0 "P" 0 300 50 H V C CNN | |||

| F1 "conn:CONN_01X05" 100 0 50 V V C CNN | |||

| F2 "" 0 0 50 H V C CNN | |||

| F3 "" 0 0 50 H V C CNN | |||

| $FPLIST | |||

| Pin_Header_Straight_1X05 | |||

| Pin_Header_Angled_1X05 | |||

| Socket_Strip_Straight_1X05 | |||

| Socket_Strip_Angled_1X05 | |||

| $ENDFPLIST | |||

| DRAW | |||

| S -50 -195 10 -205 0 1 0 N | |||

| S -50 -95 10 -105 0 1 0 N | |||

| S -50 5 10 -5 0 1 0 N | |||

| S -50 105 10 95 0 1 0 N | |||

| S -50 205 10 195 0 1 0 N | |||

| S -50 250 50 -250 0 1 0 N | |||

| X P1 1 -200 200 150 R 50 50 1 1 P | |||

| X P2 2 -200 100 150 R 50 50 1 1 P | |||

| X P3 3 -200 0 150 R 50 50 1 1 P | |||

| X P4 4 -200 -100 150 R 50 50 1 1 P | |||

| X P5 5 -200 -200 150 R 50 50 1 1 P | |||

| ENDDRAW | |||

| ENDDEF | |||

| # | |||

| # device:C_Small | |||

| # | |||

| DEF device:C_Small C 0 10 N N 1 F N | |||

| F0 "C" 10 70 50 H V L CNN | |||

| F1 "device:C_Small" 10 -80 50 H V L CNN | |||

| F2 "" 0 0 50 H V C CNN | |||

| F3 "" 0 0 50 H V C CNN | |||

| $FPLIST | |||

| C? | |||

| C_????_* | |||

| C_???? | |||

| SMD*_c | |||

| Capacitor* | |||

| $ENDFPLIST | |||

| DRAW | |||

| P 2 0 1 13 -60 -20 60 -20 N | |||

| P 2 0 1 12 -60 20 60 20 N | |||

| X ~ 1 0 100 80 D 50 50 1 1 P | |||

| X ~ 2 0 -100 80 U 50 50 1 1 P | |||

| ENDDRAW | |||

| ENDDEF | |||

| # | |||

| # device:D_Schottky | |||

| # | |||

| DEF device:D_Schottky D 0 40 N N 1 F N | |||

| F0 "D" 0 100 50 H V C CNN | |||

| F1 "device:D_Schottky" 0 -100 50 H V C CNN | |||

| F2 "" 0 0 50 H V C CNN | |||

| F3 "" 0 0 50 H V C CNN | |||

| $FPLIST | |||

| Diode_* | |||

| D-* | |||

| *SingleDiode | |||

| *_Diode_* | |||

| *SingleDiode* | |||

| D_* | |||

| $ENDFPLIST | |||

| DRAW | |||

| P 2 0 1 0 50 0 -50 0 N | |||

| P 4 0 1 8 50 50 50 -50 -50 0 50 50 N | |||

| P 6 0 1 8 -75 25 -75 50 -50 50 -50 -50 -25 -50 -25 -25 N | |||

| X K 1 -150 0 100 R 50 50 1 1 P | |||

| X A 2 150 0 100 L 50 50 1 1 P | |||

| ENDDRAW | |||

| ENDDEF | |||

| # | |||

| # device:Fuse | |||

| # | |||

| DEF device:Fuse F 0 0 N Y 1 F N | |||

| F0 "F" 80 0 50 V V C CNN | |||

| F1 "device:Fuse" -75 0 50 V V C CNN | |||

| F2 "" -70 0 50 V V C CNN | |||

| F3 "" 0 0 50 H V C CNN | |||

| $FPLIST | |||

| *Fuse* | |||

| $ENDFPLIST | |||

| DRAW | |||

| S -30 -100 30 100 0 1 10 N | |||

| P 2 0 1 0 0 100 0 -100 N | |||

| X ~ 1 0 150 50 D 50 50 1 1 P | |||

| X ~ 2 0 -150 50 U 50 50 1 1 P | |||

| ENDDRAW | |||

| ENDDEF | |||

| # | |||

| # device:POT | |||

| # | |||

| DEF device:POT RV 0 40 N N 1 F N | |||

| F0 "RV" -175 0 50 V V C CNN | |||

| F1 "device:POT" -100 0 50 V V C CNN | |||

| F2 "" 0 0 50 H V C CNN | |||

| F3 "" 0 0 50 H V C CNN | |||

| DRAW | |||

| S 40 100 -40 -100 0 1 10 N | |||

| P 2 0 1 0 100 0 60 0 N | |||

| P 3 0 1 0 45 0 90 20 90 -20 F | |||

| X 1 1 0 150 50 D 50 50 1 1 P | |||

| X 2 2 150 0 50 L 50 50 1 1 P | |||

| X 3 3 0 -150 50 U 50 50 1 1 P | |||

| ENDDRAW | |||

| ENDDEF | |||

| # | |||

| # device:R | |||

| # | |||

| DEF device:R R 0 0 N Y 1 F N | |||

| F0 "R" 80 0 50 V V C CNN | |||

| F1 "device:R" 0 0 50 V V C CNN | |||

| F2 "" -70 0 50 V V C CNN | |||

| F3 "" 0 0 50 H V C CNN | |||

| $FPLIST | |||

| R_* | |||

| Resistor_* | |||

| $ENDFPLIST | |||

| DRAW | |||

| S -40 -100 40 100 0 1 10 N | |||

| X ~ 1 0 150 50 D 50 50 1 1 P | |||

| X ~ 2 0 -150 50 U 50 50 1 1 P | |||

| ENDDRAW | |||

| ENDDEF | |||

| # | |||

| # power:GND | |||

| # | |||