commit

6cfec996d1

48 changed files with 1087 additions and 0 deletions

Unified View

Diff Options

-

BINpcbeast_2023/Automation – EISO Enterprise Co., Ltd. (1) [automation-1].mp4

-

BINpcbeast_2023/Automation – EISO Enterprise Co., Ltd. (2) [automation-2].mp4

-

BINpcbeast_2023/Controlled impedance booklet 586K.pdf

-

BINpcbeast_2023/EEE-INST-002_add1.pdf

-

BINpcbeast_2023/HZO Process for Waterproofing Electronics [HV_oVpD_yJk].mp4

-

BINpcbeast_2023/Hybrid_Capacitors_in_Energy_Applications_29654492.pdf

-

BINpcbeast_2023/IP7000_差替え本文も.png

-

BINpcbeast_2023/SP-3.jpg

-

BINpcbeast_2023/bild_1_710x532.webp

-

BINpcbeast_2023/citsintr.ppt

-

+13 -0pcbeast_2023/emc_emi_testing

-

+40 -0pcbeast_2023/notes/1.tex

-

+38 -0pcbeast_2023/notes/1.tex~

-

+108 -0pcbeast_2023/notes/2.tex

-

+40 -0pcbeast_2023/notes/2.tex~

-

+140 -0pcbeast_2023/notes/3.tex

-

+108 -0pcbeast_2023/notes/3.tex~

-

+144 -0pcbeast_2023/notes/4.tex

-

+144 -0pcbeast_2023/notes/4.tex~

-

+144 -0pcbeast_2023/notes/5.tex

-

+144 -0pcbeast_2023/notes/5.tex~

-

BINpcbeast_2023/photos/IMG_20230510_113303725.jpg

-

BINpcbeast_2023/photos/IMG_20230510_114142841.jpg

-

BINpcbeast_2023/photos/IMG_20230510_114215350.jpg

-

BINpcbeast_2023/photos/IMG_20230510_114230426_HDR.jpg

-

BINpcbeast_2023/photos/IMG_20230510_114240615_HDR.jpg

-

BINpcbeast_2023/photos/IMG_20230510_120935507.jpg

-

BINpcbeast_2023/photos/IMG_20230510_120950625_HDR.jpg

-

BINpcbeast_2023/photos/IMG_20230510_121116958_HDR.jpg

-

BINpcbeast_2023/photos/IMG_20230510_121121187_HDR.jpg

-

BINpcbeast_2023/photos/IMG_20230510_121126004_HDR.jpg

-

BINpcbeast_2023/photos/IMG_20230510_121244006.jpg

-

BINpcbeast_2023/photos/IMG_20230510_122229244_HDR.jpg

-

BINpcbeast_2023/photos/IMG_20230510_122232967.jpg

-

BINpcbeast_2023/photos/IMG_20230510_122238477_HDR.jpg

-

BINpcbeast_2023/photos/IMG_20230510_122610929_HDR.jpg

-

BINpcbeast_2023/photos/IMG_20230510_122621453_HDR.jpg

-

BINpcbeast_2023/photos/IMG_20230510_122640182_HDR.jpg

-

BINpcbeast_2023/photos/IMG_20230510_123912688.jpg

-

BINpcbeast_2023/photos/IMG_20230510_123941271.jpg

-

BINpcbeast_2023/photos/IMG_20230510_123942620_HDR.jpg

-

BINpcbeast_2023/photos/IMG_20230510_125420647_HDR.jpg

-

BINpcbeast_2023/photos/IMG_20230510_125435394.jpg

-

BINpcbeast_2023/photos/IMG_20230510_142350421_HDR.jpg

-

BINpcbeast_2023/photos/IMG_20230510_143215605_HDR.jpg

-

BINpcbeast_2023/photos/IMG_20230510_143812539.jpg

-

BINpcbeast_2023/photos/IMG_20230510_143816074.jpg

-

+24 -0pcbeast_2023/testing_via_electrical_conductivity

BIN

pcbeast_2023/Automation – EISO Enterprise Co., Ltd. (1) [automation-1].mp4

View File

BIN

pcbeast_2023/Automation – EISO Enterprise Co., Ltd. (2) [automation-2].mp4

View File

BIN

pcbeast_2023/Controlled impedance booklet 586K.pdf

View File

BIN

pcbeast_2023/EEE-INST-002_add1.pdf

View File

BIN

pcbeast_2023/HZO Process for Waterproofing Electronics [HV_oVpD_yJk].mp4

View File

BIN

pcbeast_2023/Hybrid_Capacitors_in_Energy_Applications_29654492.pdf

View File

BIN

pcbeast_2023/IP7000_差替え本文も.png

View File

BIN

pcbeast_2023/SP-3.jpg

View File

BIN

pcbeast_2023/bild_1_710x532.webp

View File

BIN

pcbeast_2023/citsintr.ppt

View File

+ 13

- 0

pcbeast_2023/emc_emi_testing

View File

| @ -0,0 +1,13 @@ | |||||

| i think i would enjoy a career in self employed emc/emi testing. | |||||

| like just specialize in it. | |||||

| get my own faraday setup. | |||||

| get some testing equipment. | |||||

| the paranoiac nature of it appeals to me. | |||||

| but also just curiousity of RF emissions from equipment. | |||||

+ 40

- 0

pcbeast_2023/notes/1.tex

View File

| @ -0,0 +1,40 @@ | |||||

| \documentclass[11pt]{article} | |||||

| %Gummi|065|=) | |||||

| \usepackage{graphicx} | |||||

| \usepackage{caption} | |||||

| \usepackage{xcolor} | |||||

| \usepackage[vcentering,dvips]{geometry} | |||||

| \geometry{papersize={6in,9in},total={4.5in,6.8in}} | |||||

| \title{\textbf{Door Alarm}} | |||||

| \author{Steak Electronics} | |||||

| \date{} | |||||

| \begin{document} | |||||

| \maketitle | |||||

| %\tableofcontents | |||||

| \textcolor{green!60!blue!70}{ | |||||

| \section{PCBEast 2023}} | |||||

| PCBEast 2023 was a three day conference and 1 day expo in Boxboro, MA. It was located at the Boxboro Regency Hotel, and was about 3 minutes from the intersection of route 2 and route 495. This expo was about 1 medium sized function room, so a smaller expo. There were about 4 aisles of maybe 12 companies each, so about 50 companies. Companies were global, but mostly US, with some from Asia and even less from the EU. The main company here was PCB Fabs, but there were a number of supporting businesses, and visiting an event like this is relevant for anyone who designs a PCB, not just fabs. Any EE might benefit from an event like this. | |||||

| I'm going to write up a bit on expos in my third book, so if you are interested in general expo advice (from someone who is a fan of visiting any type of expo) see that. This article is going to be a writeup of my notes from the expo. I typically write questions beforehand, and then visit each booth asking them my questions, branching off into new ideas as they come. So This list will show what I learned from the vendors I visited. Note that I didn't have time to visit all the vendors, as I procrastinated until the night before to write the questions by accident (haven't been to enough expos lately), so I only visited a selection of vendors. Here we go. | |||||

| \section{Q & A Section} | |||||

| I didn't actually visit the companies in this order as I started in the middle of the map, but I'll just write them down in order of my notes. And this section won't include the questions but will just be a writeup on each vendor. | |||||

| \subsection{Accurate Circuit Engineering} | |||||

| A fab. He mentioned copper coins as heatsinks on his website. Instead of using a traditional heatsink, he is using semi soft copper from Mcmaster Carr or Grainger, milled in a US xxxx Tools mill (can't read my notes - Sorry!). The copper coins are essentially a small cutout of copper. Instead of having a whole copper layer internally as a heatsink (which is possible) he uses the coins. Also the coins can go on the outer layers. They are very small, and don't really resemble heatsinks. See the photos. He prefers Rogers Cool Span epoxy to attach the coins to the board as this epoxy can cure in low temperatures or even in a vacuum. This is a conductive epoxy/heatsinking compound. It's possible to put the copper coins on inner layers (this will become more interesting later as we talk about embedding dies inbetween layers of a pcb...). The enig vs. electrolytic gold plating: Enig is typically 2-4 microinches, while elctrolytic can be as high as 50-100 micro inches. The enig can't get too thick or it will corrode a below layer. | |||||

| \subsection{Polar Instruments} | |||||

| Polar instruments makes a calculator type software (see their website) to help improve yield with high speed and inner layers of a PCB. I asked if there was a scripting interface available, but currently you would export from the program to Excel or XML and then act on that data. I'm not entirely sure if scripting is helpful for this software, but I suppose it can't hurt so it was the one question I had from looking at their website. | |||||

| For an idea of what they do, see the Transline section of the PCB Calculator on KiCad and then consider what they software woould look like if this was a full fledged program. Obviously there is a lot of potential for improvement in Kicad, which really just introduces you to the concept. | |||||

| From my research beforehand, the need for software like this is to take high speed signals, and put them in a type of coaxial like trace on the circuit board. There are different ways to do this, but you could, like coax, put a dielectric layer, then a conductive ground around the signal, just in pcb form. The PCB is a component. Impedance is usually 40-120ohms (think 50 or 75ohms for radio or tv). Higher impedance is tougher to handle as the traces get smaller. Typically, 28,50,75, or 100 ohms.Differential wires \gt coaxial type wires. | |||||

| You should also be aware that when pcb is etched in a subtractive process (pre-Ultra HDI) that the traces get a type of pyramidal shape when cut in a profile or cross section. This has effects on the signal as well. There is a good photo, and I'll include it in the git repo for this article (2023 git). | |||||

| \subsection{} | |||||

| \end{document} | |||||

+ 38

- 0

pcbeast_2023/notes/1.tex~

View File

| @ -0,0 +1,38 @@ | |||||

| \documentclass[11pt]{article} | |||||

| %Gummi|065|=) | |||||

| \usepackage{graphicx} | |||||

| \usepackage{caption} | |||||

| \usepackage{xcolor} | |||||

| \usepackage[vcentering,dvips]{geometry} | |||||

| \geometry{papersize={6in,9in},total={4.5in,6.8in}} | |||||

| \title{\textbf{Door Alarm}} | |||||

| \author{Steak Electronics} | |||||

| \date{} | |||||

| \begin{document} | |||||

| \maketitle | |||||

| %\tableofcontents | |||||

| \textcolor{green!60!blue!70}{ | |||||

| \section{Attiny Solar Energy Harvest Tests}} | |||||

| I have the following: | |||||

| \begin{itemize} | |||||

| \item Solar panels | |||||

| \item Attiny 10 | |||||

| \end{itemize} | |||||

| To this list, I will add a supercap, and an energy harvesting IC. The goal being to load the super cap during the day, and to run 24/7. I will need an exceptionally low power micro. The super cap will need to be about 3.3V or 5V. | |||||

| \subsection{Micro Considerations} | |||||

| The Arduino Atmega328P is not an option. I'm looking to have a current draw of only 1mA max, (ideally 500uA) when active. Moteino is also not an option for this. Those are made for batteries. I want to be battery free. A super cap, however can be used to store energy. I'll get to that shortly. | |||||

| For micros, I have some Attiny10 on hand, and these have a reasonably low power pull in active mode. Let's build those up first. What will the micro do? No idea. I haven't a clue. | |||||

| \subsection{Energy Storage} | |||||

| I don't want a battery. Let's go with a super cap. The solar panels will only be active some of the time, so I will want to harvest energy with some kind of IC into the cap when the sun is out.\footnote{Reference: www.analog.com/media/en/technical-documentation/technical-articles/solarenergyharvesting.pdf is a start. I'll need to do more research.} | |||||

| \end{document} | |||||

+ 108

- 0

pcbeast_2023/notes/2.tex

View File

| @ -0,0 +1,108 @@ | |||||

| \documentclass[11pt]{article} | |||||

| %Gummi|065|=) | |||||

| \usepackage{graphicx} | |||||

| \usepackage{caption} | |||||

| \usepackage{xcolor} | |||||

| \usepackage[vcentering,dvips]{geometry} | |||||

| \geometry{papersize={6in,9in},total={4.5in,6.8in}} | |||||

| \title{\textbf{Door Alarm}} | |||||

| \author{Steak Electronics} | |||||

| \date{} | |||||

| \begin{document} | |||||

| \maketitle | |||||

| %\tableofcontents | |||||

| \textcolor{green!60!blue!70}{ | |||||

| \section{PCBEast 2023}} | |||||

| PCBEast 2023 was a three day conference and 1 day expo in Boxboro, MA. It was located at the Boxboro Regency Hotel, and was about 3 minutes from the intersection of route 2 and route 495. This expo was about 1 medium sized function room, so a smaller expo. There were about 4 aisles of maybe 12 companies each, so about 50 companies. Companies were global, but mostly US, with some from Asia and even less from the EU. The main company here was PCB Fabs, but there were a number of supporting businesses, and visiting an event like this is relevant for anyone who designs a PCB, not just fabs. Any EE might benefit from an event like this. | |||||

| I'm going to write up a bit on expos in my third book, so if you are interested in general expo advice (from someone who is a fan of visiting any type of expo) see that. This article is going to be a writeup of my notes from the expo. I typically write questions beforehand, and then visit each booth asking them my questions, branching off into new ideas as they come. So This list will show what I learned from the vendors I visited. Note that I didn't have time to visit all the vendors, as I procrastinated until the night before to write the questions by accident (haven't been to enough expos lately), so I only visited a selection of vendors. Here we go. | |||||

| \section{Q & A Section} | |||||

| I didn't actually visit the companies in this order as I started in the middle of the map, but I'll just write them down in order of my notes. And this section won't include the questions but will just be a writeup on each vendor. | |||||

| \subsection{Accurate Circuit Engineering} | |||||

| A fab. He mentioned copper coins as heatsinks on his website. Instead of using a traditional heatsink, he is using semi soft copper from Mcmaster Carr or Grainger, milled in a US xxxx Tools mill (can't read my notes - Sorry!). The copper coins are essentially a small cutout of copper. Instead of having a whole copper layer internally as a heatsink (which is possible) he uses the coins. Also the coins can go on the outer layers. They are very small, and don't really resemble heatsinks. See the photos. He prefers Rogers Cool Span epoxy to attach the coins to the board as this epoxy can cure in low temperatures or even in a vacuum. This is a conductive epoxy/heatsinking compound. It's possible to put the copper coins on inner layers (this will become more interesting later as we talk about embedding dies inbetween layers of a pcb...). The enig vs. electrolytic gold plating: Enig is typically 2-4 microinches, while elctrolytic can be as high as 50-100 micro inches. The enig can't get too thick or it will corrode a below layer. | |||||

| \subsection{Polar Instruments} | |||||

| Polar instruments makes a calculator type software (see their website) to help improve yield with high speed and inner layers of a PCB. I asked if there was a scripting interface available, but currently you would export from the program to Excel or XML and then act on that data. I'm not entirely sure if scripting is helpful for this software, but I suppose it can't hurt so it was the one question I had from looking at their website. | |||||

| For an idea of what they do, see the Transline section of the PCB Calculator on KiCad and then consider what they software woould look like if this was a full fledged program. Obviously there is a lot of potential for improvement in Kicad, which really just introduces you to the concept. | |||||

| From my research beforehand, the need for software like this is to take high speed signals, and put them in a type of coaxial like trace on the circuit board. There are different ways to do this, but you could, like coax, put a dielectric layer, then a conductive ground around the signal, just in pcb form. The PCB is a component. Impedance is usually 40-120ohms (think 50 or 75ohms for radio or tv). Higher impedance is tougher to handle as the traces get smaller. Typically, 28,50,75, or 100 ohms.Differential wires \gt coaxial type wires. | |||||

| You should also be aware that when pcb is etched in a subtractive process (pre-Ultra HDI) that the traces get a type of upside down pyramidal shape when cut in a profile or cross section. This is because the etchant attacks the bottom part of the trace slightly more (gravity?) This has effects on the signal as well. There is a good photo, and I'll include it in the git repo for this article (2023 git) where you can clearly see that pcb traces are not square when etched. I'd imagine milling pcbs would be different. | |||||

| \subsection{Facet LLC} | |||||

| An overseas fab who also does plastic injection molding design work. They ship out the injection to manufacturers in Asia, but have designers on staff. There is no website for the injection molding yet, but the description on PCBEast did have it listd. One thing that was mentioned to be aware of with Injection molds, was that the molds have a maintenance fee. Over time, the molds will wear out, so this cost is usually included as you go along. However, if you don't use the molds for say, a number of years, and then contact the manufacturers again, they will charge you a maintenance fee to restart the mold. I'm just guessing here, but I'd imagine that they don't keep the molds in inventory, so after a number of years they probably have to make it again. In any case, don't be surprised if there is a maintenance fee. | |||||

| \subsection{Acdi} | |||||

| A fab house from MD. Also do prototyping. His company has a couple locations, including one in Branford, CT. I asked him whether they had different capabilities at the Brandford location vs. MD but he said that his company keeps all equipment standardized across the different locations. He also mentioned that this is not typical, though I asked one other company which happened to also standardize, so I guess it can go either way. | |||||

| One strength: they use Silicon Expert sourcing software, which can give information parts such as obsolecence notices. | |||||

| \subsection{Actnano} | |||||

| This company is a conformal coating company. Their largest customer is automotive. Consumer and solar are also customers. Their company is based around non-pfa coatings. The founder was a Philips employee who saw the toxicity of pfa conformal coatings in electronics, and thus started the business. They has a research office in Cambridge, and manufacture in Wisconsin and the greater Boston area. If you are a consumer who is interested in the coating, you CAN buy it direct from them. | |||||

| The two main coatings they have are either silicone or not silicone based. The automotive industry is worried about migration of silicone, so they don't use that. Though, other industries use the silicone based coating. | |||||

| \subsection{NCAB Group} | |||||

| A PCB fab in NH. He recommended the Pick and Place podcast from Deerfield, MA. He was giving out a PCB Design Guidelines book, though I have too many books at the moment. We talked a bit about the Ultra HDI additive process. As mentioned above typical (down to 3 mill) pcb etching is a subtractive process, but it leaves you with the bowed or upside down pyramid looking traces, and this doesn't work for smaller geometries (such as the 25,50,75,100 micron that ultra HDI is able to do). The ultra HDI process is additive, and there are different ways to do it. Such as MSAP, ASAP, or SAP. I will come back to this more shortly. The actual process to use hasn't been standardized yet, and he mentioned that some fabs were reluctant to start it (while someone later mentioned that the process actually was easy - there was some disagreement on this point). | |||||

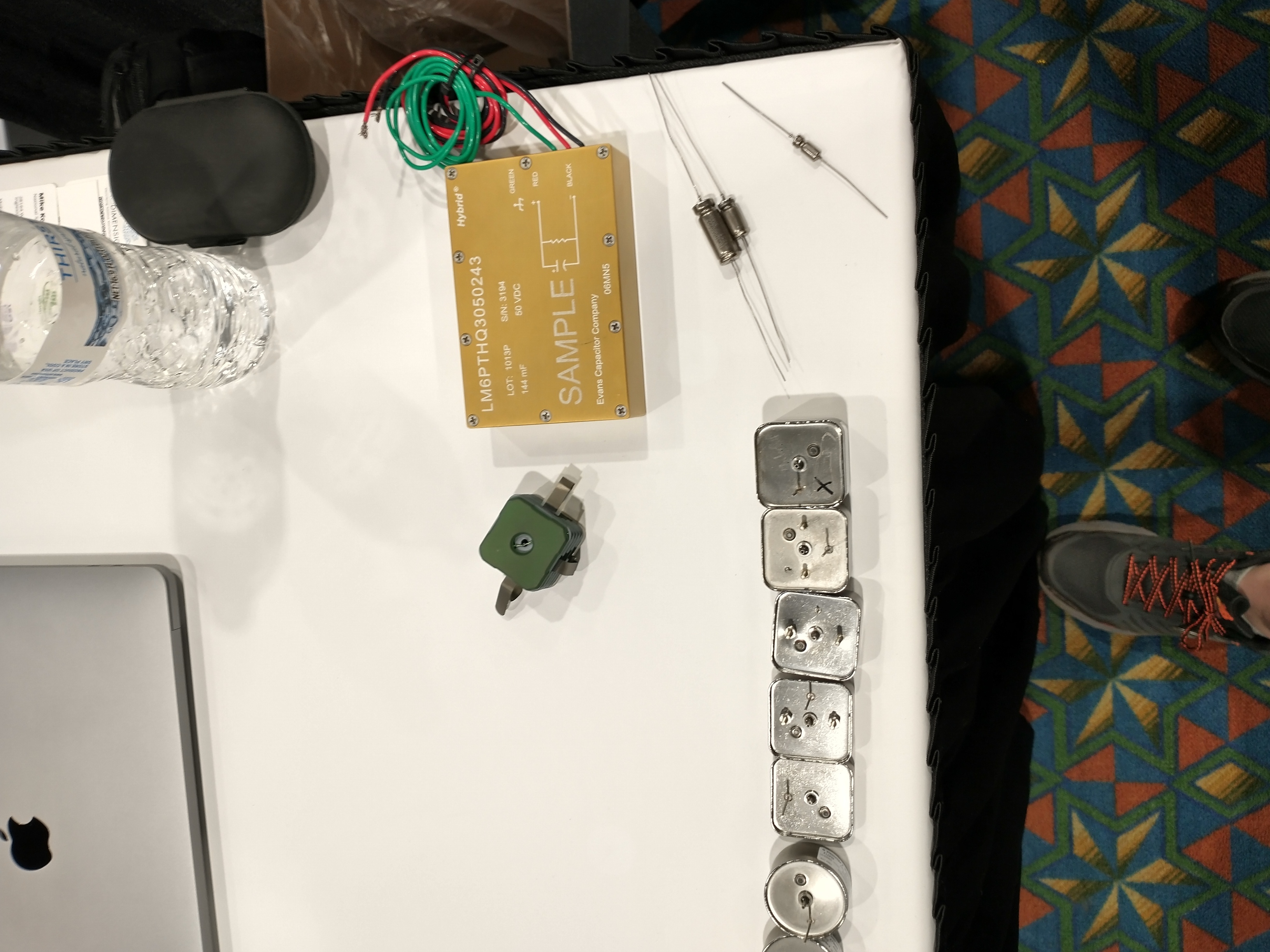

| \subsection{Quantic Ohmega & Evans} | |||||

| Quantic is a large parent company, that has gobbled up a number of smaller companies. Ohmega and Evans were the two demonstrating here, but there were a couple others they had fliers for. Ohmega is a producer of copper foil for PCBs, while Evans is a high reliability capacitor manufacturer. Since copper foils is really just for fabs, let's talk about the capacitors. | |||||

| The evans capactitors are high reliability (from apache helicopters to satellites) hermetically sealed type of tantalum capactitor (some side band hybrid tantalum, not standard yellow caps). For example, the Hawkeye radar plane has 700 of these capacitors in it's goofy looking circular antenna that sits above the plane. | |||||

| How do they test these for space? There is a standard by Nasa, INS002, which is a rigorous (and expensive) test for space devices. There is a screening section of the test, followed by a qualification section. I'm not going to research the test now, but you can look it up online. These days a lot more companies are been going to space and they have to cut costs a bit, so instead of doing the whole INS002 test, this tech recommends choosing specific tests that apply to your product. He had actually just done a webinar on this, coincidentally. So, if you are concerned about vibration, then do that test. And so on. | |||||

| For testing MTBF, they will look at field data. They will also put components, powered on, in an oven pre-heated to 85 degrees celcius, and leave them for 2000 hours, checking them at every 500 hours. Afterwards they will check the specs to make sure nothing has gone terribly wrong. | |||||

| With the highest end customers, what they will do is take for example, 40 capacitors, run the INS002 test, then take only ten out of those 40 for actual use. | |||||

| \subsection{Trilogy-Net} | |||||

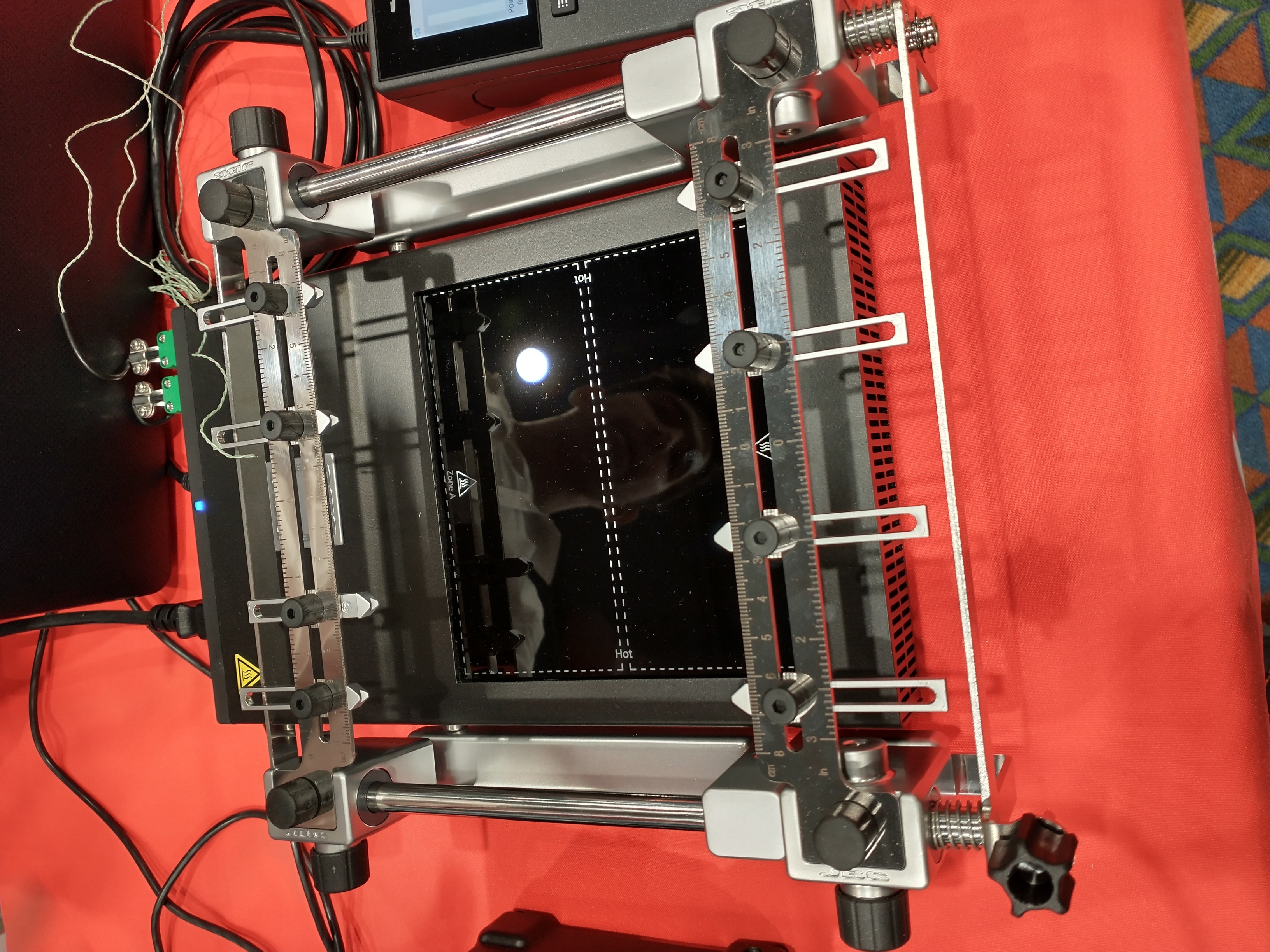

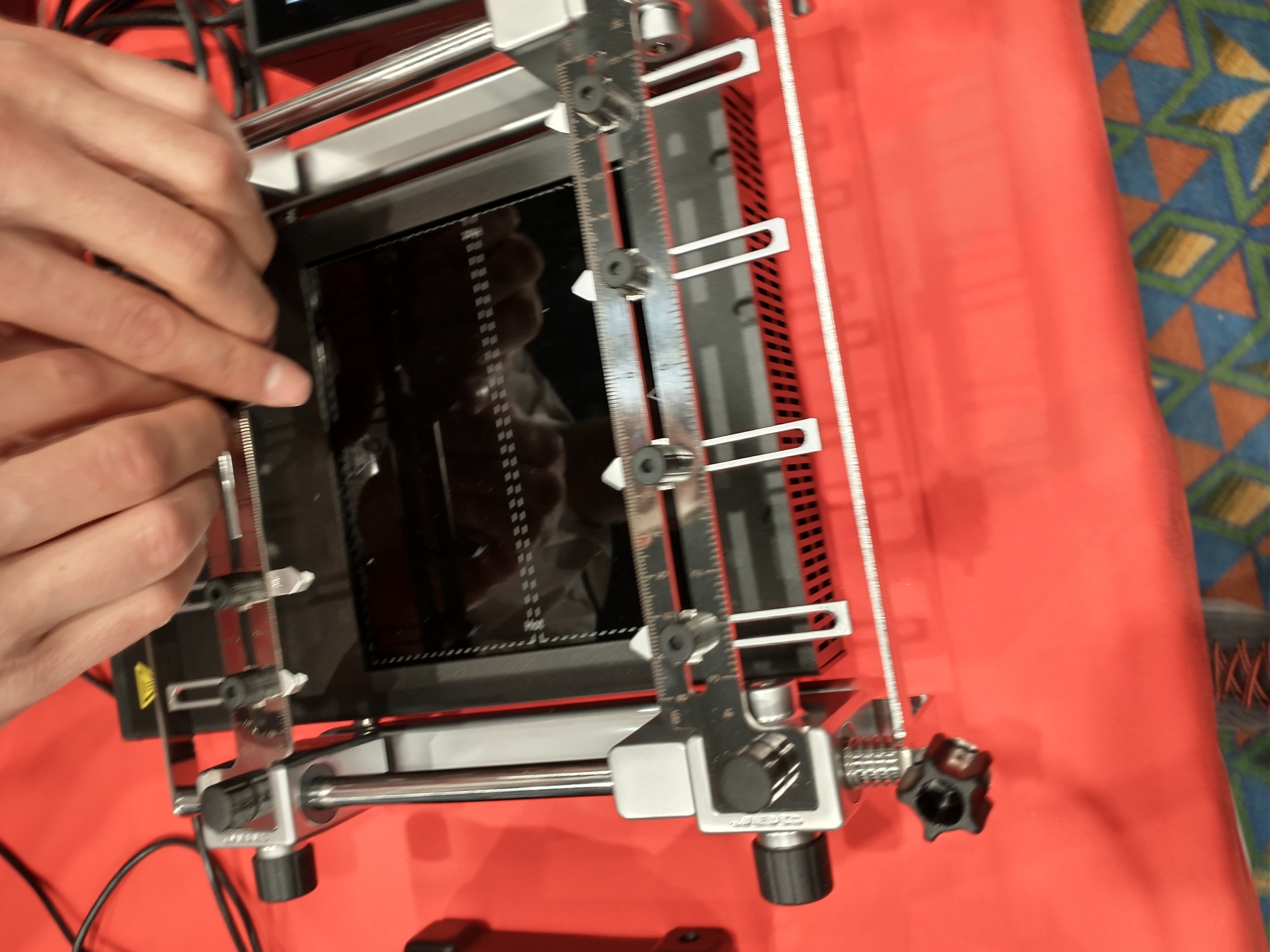

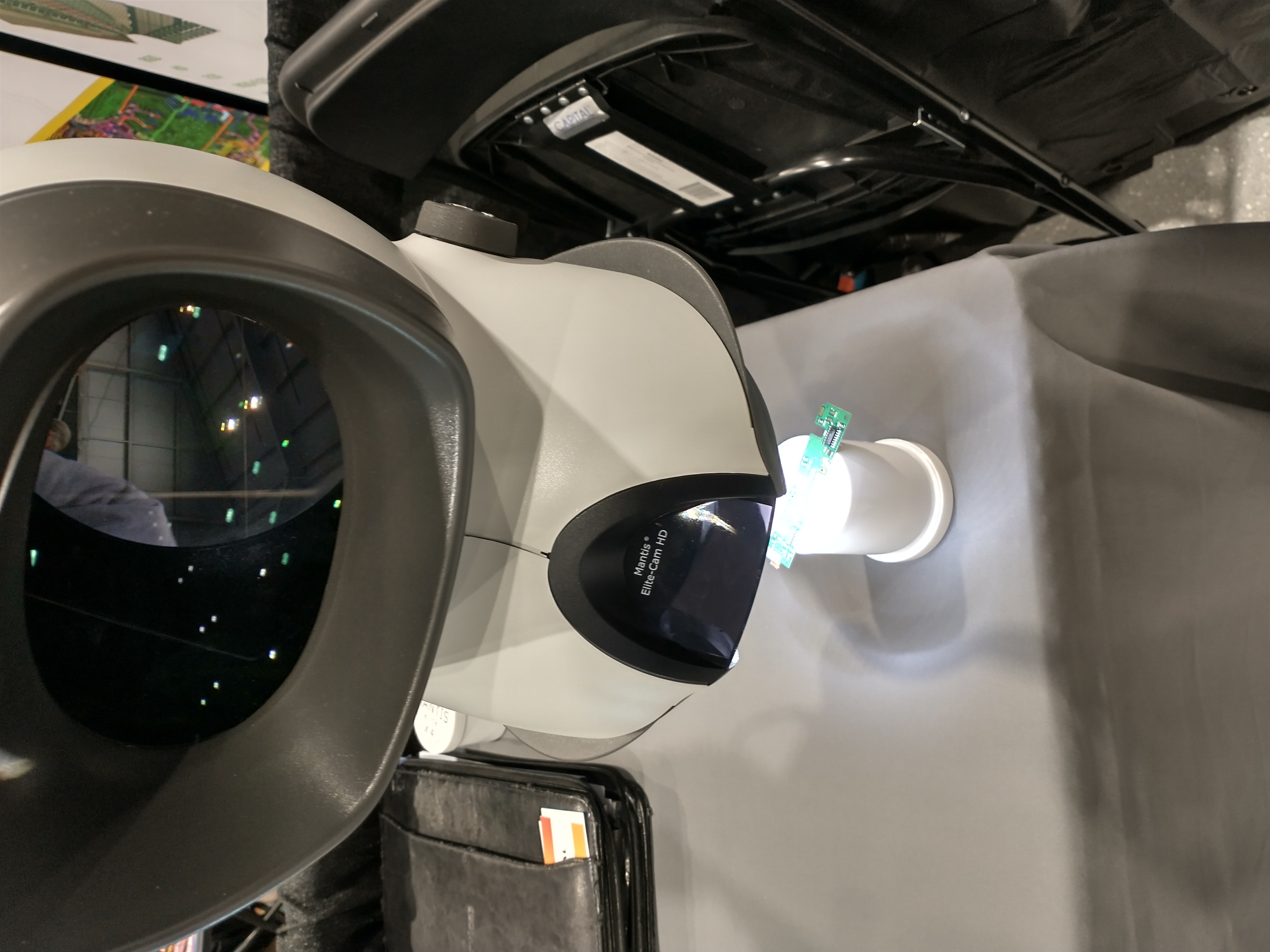

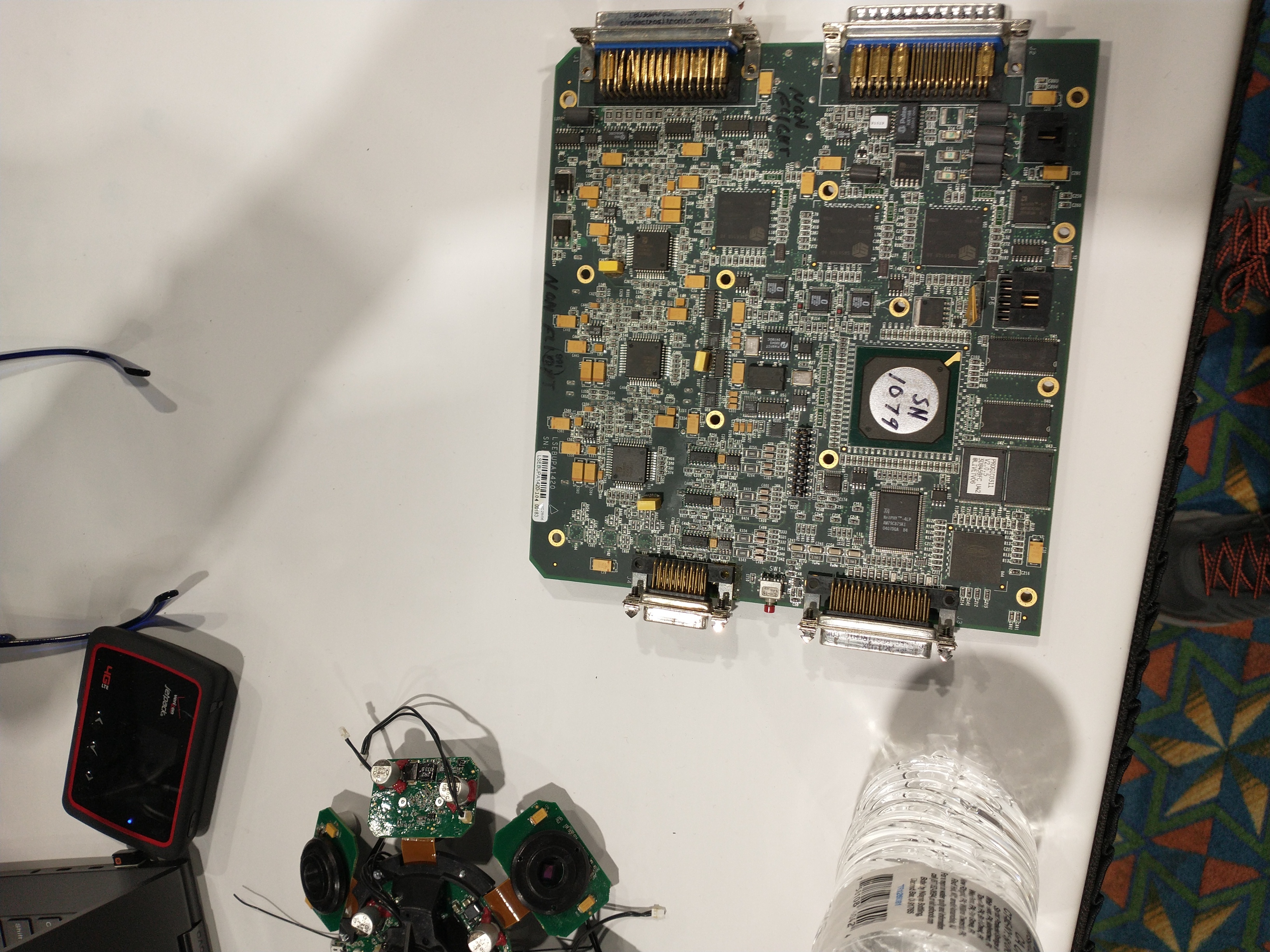

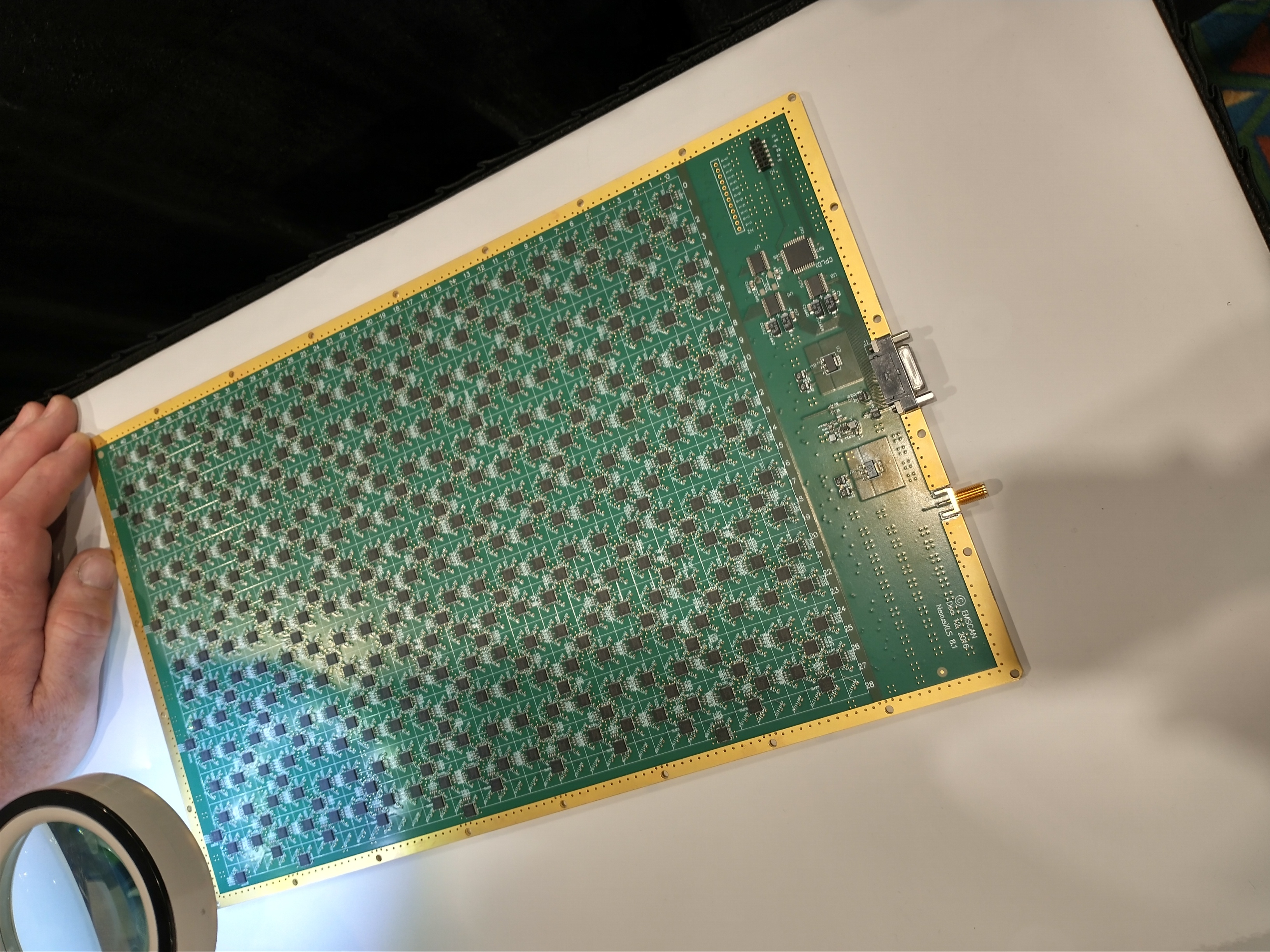

| A fab. They had an interesting EMI/EMC compliance test that he would run for \$500, or even free for their pcb customers. Using EM Viewer software, and a custom board built of a number of RF Antennas (see photos), they would place the pcb on top of this RF board, and look for any spurious signals on a spectrum analyzer. | |||||

| So if you want to do some precompliance testing, you can make a custom board like his. I was able to get a video of the chips | |||||

| they used for the board, and he didn't mind, so maybe I'll consider making a similar board. I have a feeling that EMI/EMC compliance testing might be something I'd enjoy. Find a niche that you can dive into. This is one that doesn't take a lifetime, and is practical. | |||||

| \subsection{Metallic Resources} | |||||

| A solder company from Ohio. They sell direct. They are not on Digikey. They sell a number of solder products, flux, bar, paste, etc... They specialize in recycling lead and silver solder. They sell to consumers, I believe. | |||||

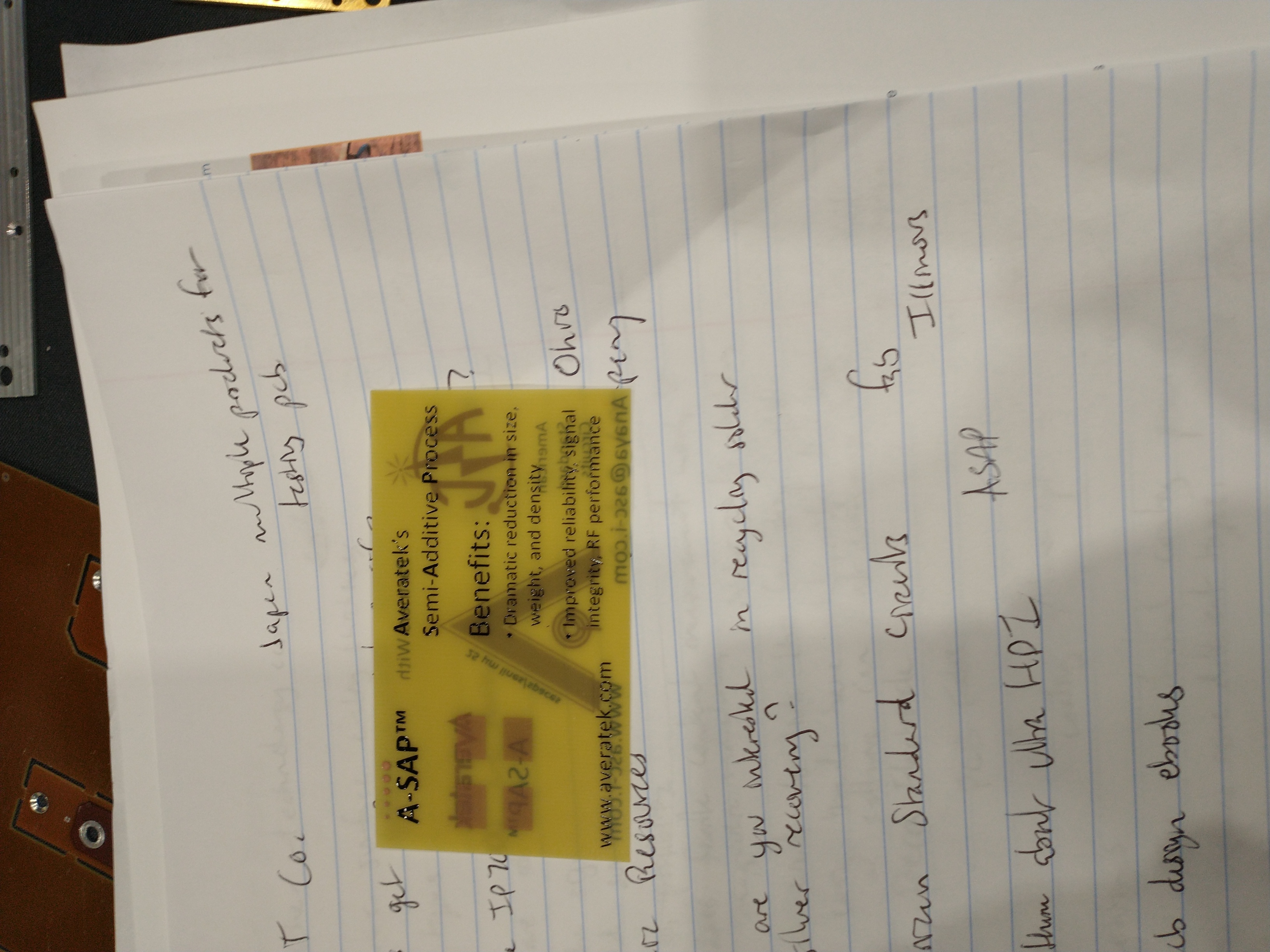

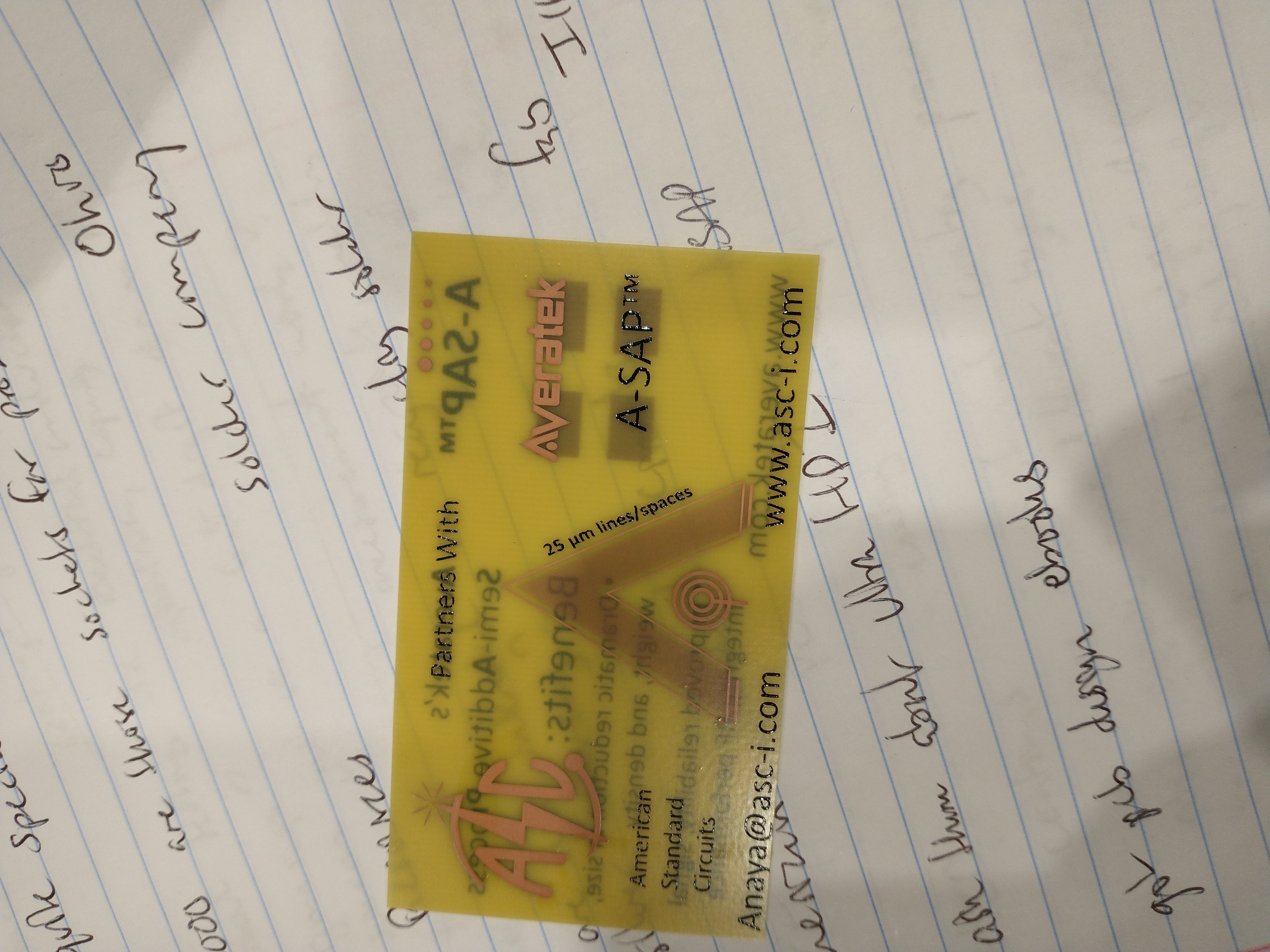

| \subsection{American Standard Circuits} | |||||

| A fab from Illinois. An old timer, had been in the business since 1978, He had a bit to say about ultra HDI. The ASAP process for ultra HDI (high density interconnects) can get down to 25 microns, maybe even lower. While the MSAP process can only go down to 30 microns. Given the track layers are so thin, at 25 microns, it's possible for him to take the place of substrates that would usually be on silicon. I was thinking like SOC, like the pocket beagle but i'm not sure that is what he had in mind. He mentioned it would be feasible to put a die inside the layers of the pcb, and then route it out via the 25 micron traces. That is a bit fascinating, and slightly horrific for security folk. ICs embedded in the layers of the pcb. I guess you would have to do xray analysis to see them. One benefit of the ultra HDI as well, means smaller boards. So instead of a 20 layer board, you could get it down to 4. That is a cost savings that justifies the ultra HDI. This is contrary to what NCAB group said. He also mentioned that it's possible to mix ultra HDI with standard 3 mil etching, if for some reason you wanted to do this, and it's not necessarily more expensive. Although you lose the size reduction if you go to 3 mil traces of course. | |||||

| His capability was as low as 12.5 microns reportedly. He showed me a business card sized pcb with 25, 50, 75, and 100 micron traces on it. There is a photo in the git repo. A louvre was necessary to see the 25 mil traces. The 100 mil traces are visible through the naked eye, and also through the photo. | |||||

| SAP stands for semi-additive process (ASAP,MSAP,SAP above). For copper trace peel strength, I think he mentioned that standard numbers are around 4lbs. / inch for FR4. Teflon is much higher, and flex can also get quite high, perhaps 25 lbs. / inch. I forget if there was some connection between the ultra HDI and the peel strength (may have been). | |||||

| One simple difference between traditional 3 mil etching pcbs (subtractive) and the additive process (ultra HDI) is this simple fact: Traditional etching starts out with the copper foil layer and then subtracts, while the additive process has a plating part to it. The copper isn't traced from foil, but from a chemical reaction. | |||||

| \subsection{Fischer Technology} | |||||

| This is a tool maker, they have a couple of products for measuring surface coating thickness. They sell to pcb fabs, but also to other industries. Their website has some of their products, but for example the Sigmascope measures resistivity on non-ferrite metals such as aluminum and copper. It is a handheld device and has a non conductive polymer tip which is placed on the metal. By inducing eddy currents in the metal, they detect the resistivity. | |||||

| For ferrite metals, there is a separate type of handheld tool. This one works on magnetic induction. It's used for solder joints, and welding (possibly some other applications, I forget now). | |||||

| They also had a box type appliance, where you place a pcb in, and via x ray fluorescence, it will give you the surface coating layer of gold. This is used for enig finishes, where the fabs prefer it to be on the lower end of 2-4 micro inches(might have the wrong measure). They are a manufacturer of these devices. | |||||

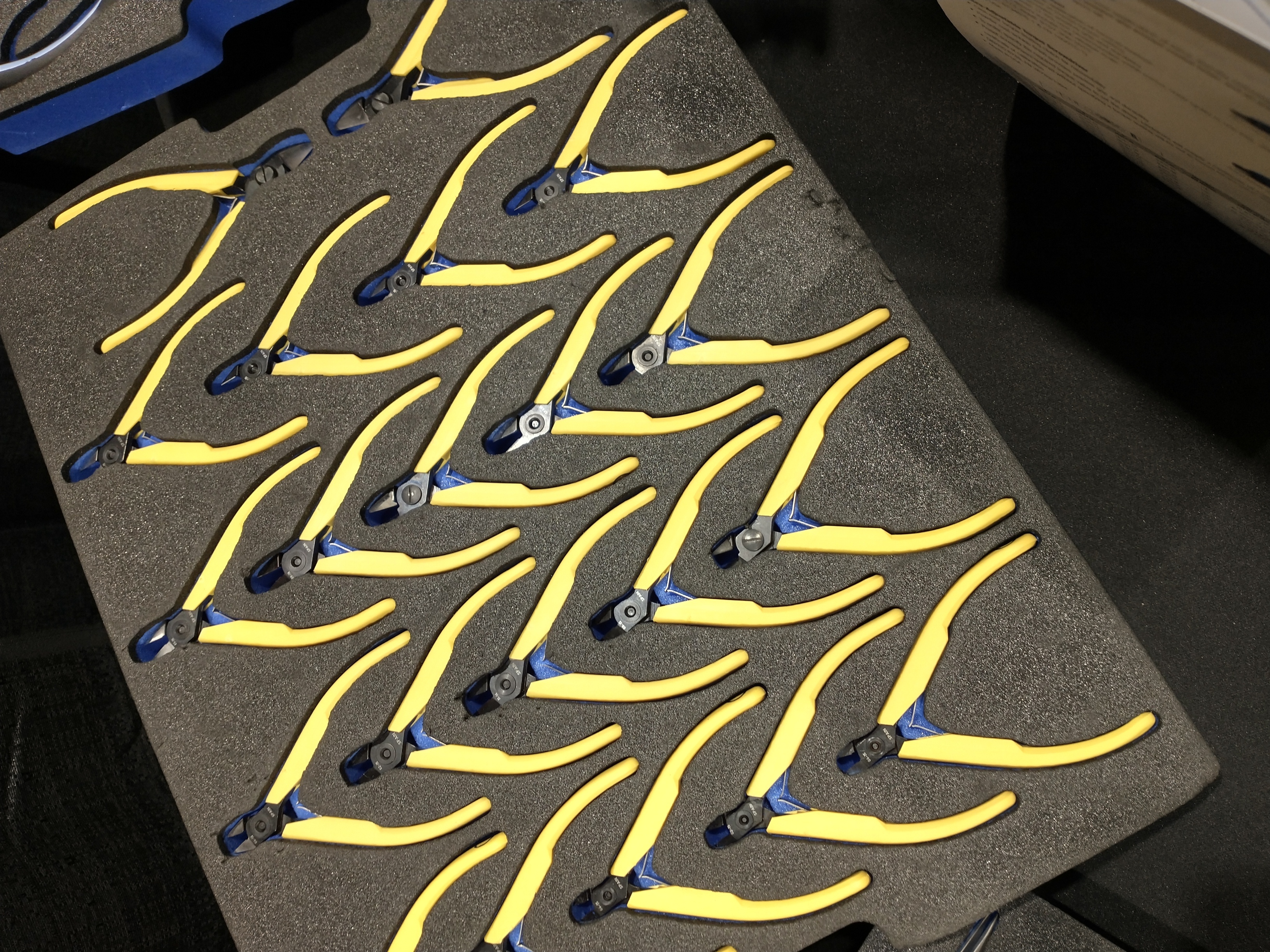

| \subsection{JBC} | |||||

| You should know already, that JBC is a manufacturer of soldering irons. I took some pictures of two things I found interesting. They sell a nice spring loaded and adjustable pcb holder model number: PHS-SA (see photos in git). below that was a separate heater. It turns on extremely quickly. It's some kind of heat below glass, yet the heat quickly radiates up. A fun piece of equipment. That with the pcb holder was the most interesting. They also had a very fine tipped hot air gun, at a thickness of some 2mm or so. Really small for hot air. It's easily confused with a soldering iron. | |||||

| \subsection{xDry} | |||||

| Another Texan. Why is it that I can often tell a texan at expos. This is not the first time I've met one at such, and the accent always gives them away (though to be fair, there was another texan at this expo which did not have an accent). Jokes aside, xDry sells drying storage cabinets. There are different sized models. They work via dessicant. They are not temperature controlled, though they have the option for nitrogen to be put in them for an inert atmosphere. The nitrogen also helps, for the recovery time, for if you open the door to take out a device inside, the ambient (moist) air will rush in. The nitrogen is used to quickly bring it back down to a dry atmosphere. | |||||

| Since my family company has or is actually getting nitrogen on site (and it's not an unreasonable expense from what I understand) this is not a bad addition to the drying cabinets. For the temperature controlled drying areas, he mentioned that there is another company, Thermotron, to look at for those. | |||||

| \subsection{Downstream Technologies} | |||||

| This is a software company. Their main software is CAM350 (office365?), although they have another one named Blueprint which is up and coming. The rep mentioned that their software was likely used to make some modern cellphones. I haven't heard of this, so will have to investigate. Cam350 is how I feel when my surveillance cameras don't work. (They see all but 10 degrees...? The 10 degrees you need...) | |||||

| CAM350 reads ODB files which are a common output format. These are not to be confused with Libreoffice' ODB files. There is some discussion of ODB on the kicad forums: https://forum.kicad.info Apparently there is some contention between Gerber, ODB, and IPC-2581 to become the defacto standard for output and assembly from CAD software. | |||||

| \end{document} | |||||

+ 40

- 0

pcbeast_2023/notes/2.tex~

View File

| @ -0,0 +1,40 @@ | |||||

| \documentclass[11pt]{article} | |||||

| %Gummi|065|=) | |||||

| \usepackage{graphicx} | |||||

| \usepackage{caption} | |||||

| \usepackage{xcolor} | |||||

| \usepackage[vcentering,dvips]{geometry} | |||||

| \geometry{papersize={6in,9in},total={4.5in,6.8in}} | |||||

| \title{\textbf{Door Alarm}} | |||||

| \author{Steak Electronics} | |||||

| \date{} | |||||

| \begin{document} | |||||

| \maketitle | |||||

| %\tableofcontents | |||||

| \textcolor{green!60!blue!70}{ | |||||

| \section{PCBEast 2023}} | |||||

| PCBEast 2023 was a three day conference and 1 day expo in Boxboro, MA. It was located at the Boxboro Regency Hotel, and was about 3 minutes from the intersection of route 2 and route 495. This expo was about 1 medium sized function room, so a smaller expo. There were about 4 aisles of maybe 12 companies each, so about 50 companies. Companies were global, but mostly US, with some from Asia and even less from the EU. The main company here was PCB Fabs, but there were a number of supporting businesses, and visiting an event like this is relevant for anyone who designs a PCB, not just fabs. Any EE might benefit from an event like this. | |||||

| I'm going to write up a bit on expos in my third book, so if you are interested in general expo advice (from someone who is a fan of visiting any type of expo) see that. This article is going to be a writeup of my notes from the expo. I typically write questions beforehand, and then visit each booth asking them my questions, branching off into new ideas as they come. So This list will show what I learned from the vendors I visited. Note that I didn't have time to visit all the vendors, as I procrastinated until the night before to write the questions by accident (haven't been to enough expos lately), so I only visited a selection of vendors. Here we go. | |||||

| \section{Q & A Section} | |||||

| I didn't actually visit the companies in this order as I started in the middle of the map, but I'll just write them down in order of my notes. And this section won't include the questions but will just be a writeup on each vendor. | |||||

| \subsection{Accurate Circuit Engineering} | |||||

| A fab. He mentioned copper coins as heatsinks on his website. Instead of using a traditional heatsink, he is using semi soft copper from Mcmaster Carr or Grainger, milled in a US xxxx Tools mill (can't read my notes - Sorry!). The copper coins are essentially a small cutout of copper. Instead of having a whole copper layer internally as a heatsink (which is possible) he uses the coins. Also the coins can go on the outer layers. They are very small, and don't really resemble heatsinks. See the photos. He prefers Rogers Cool Span epoxy to attach the coins to the board as this epoxy can cure in low temperatures or even in a vacuum. This is a conductive epoxy/heatsinking compound. It's possible to put the copper coins on inner layers (this will become more interesting later as we talk about embedding dies inbetween layers of a pcb...). The enig vs. electrolytic gold plating: Enig is typically 2-4 microinches, while elctrolytic can be as high as 50-100 micro inches. The enig can't get too thick or it will corrode a below layer. | |||||

| \subsection{Polar Instruments} | |||||

| Polar instruments makes a calculator type software (see their website) to help improve yield with high speed and inner layers of a PCB. I asked if there was a scripting interface available, but currently you would export from the program to Excel or XML and then act on that data. I'm not entirely sure if scripting is helpful for this software, but I suppose it can't hurt so it was the one question I had from looking at their website. | |||||

| For an idea of what they do, see the Transline section of the PCB Calculator on KiCad and then consider what they software woould look like if this was a full fledged program. Obviously there is a lot of potential for improvement in Kicad, which really just introduces you to the concept. | |||||

| From my research beforehand, the need for software like this is to take high speed signals, and put them in a type of coaxial like trace on the circuit board. There are different ways to do this, but you could, like coax, put a dielectric layer, then a conductive ground around the signal, just in pcb form. The PCB is a component. Impedance is usually 40-120ohms (think 50 or 75ohms for radio or tv). Higher impedance is tougher to handle as the traces get smaller. Typically, 28,50,75, or 100 ohms.Differential wires \gt coaxial type wires. | |||||

| You should also be aware that when pcb is etched in a subtractive process (pre-Ultra HDI) that the traces get a type of pyramidal shape when cut in a profile or cross section. This has effects on the signal as well. There is a good photo, and I'll include it in the git repo for this article (2023 git). | |||||

| \subsection{} | |||||

| \end{document} | |||||

+ 140

- 0

pcbeast_2023/notes/3.tex

View File

| @ -0,0 +1,140 @@ | |||||

| \documentclass[11pt]{article} | |||||

| %Gummi|065|=) | |||||

| \usepackage{graphicx} | |||||

| \usepackage{caption} | |||||

| \usepackage{xcolor} | |||||

| \usepackage[vcentering,dvips]{geometry} | |||||

| \geometry{papersize={6in,9in},total={4.5in,6.8in}} | |||||

| \title{\textbf{Door Alarm}} | |||||

| \author{Steak Electronics} | |||||

| \date{} | |||||

| \begin{document} | |||||

| \maketitle | |||||

| %\tableofcontents | |||||

| \textcolor{green!60!blue!70}{ | |||||

| \section{PCBEast 2023}} | |||||

| PCBEast 2023 was a three day conference and 1 day expo in Boxboro, MA. It was located at the Boxboro Regency Hotel, and was about 3 minutes from the intersection of route 2 and route 495. This expo was about 1 medium sized function room, so a smaller expo. There were about 4 aisles of maybe 12 companies each, so about 50 companies. Companies were global, but mostly US, with some from Asia and even less from the EU. The main company here was PCB Fabs, but there were a number of supporting businesses, and visiting an event like this is relevant for anyone who designs a PCB, not just fabs. Any EE might benefit from an event like this. | |||||

| I'm going to write up a bit on expos in my third book, so if you are interested in general expo advice (from someone who is a fan of visiting any type of expo) see that. This article is going to be a writeup of my notes from the expo. I typically write questions beforehand, and then visit each booth asking them my questions, branching off into new ideas as they come. So This list will show what I learned from the vendors I visited. Note that I didn't have time to visit all the vendors, as I procrastinated until the night before to write the questions by accident (haven't been to enough expos lately), so I only visited a selection of vendors. Here we go. | |||||

| \section{Q & A Section} | |||||

| I didn't actually visit the companies in this order as I started in the middle of the map, but I'll just write them down in order of my notes. And this section won't include the questions but will just be a writeup on each vendor. | |||||

| \subsection{Accurate Circuit Engineering} | |||||

| A fab. He mentioned copper coins as heatsinks on his website. Instead of using a traditional heatsink, he is using semi soft copper from Mcmaster Carr or Grainger, milled in a US xxxx Tools mill (can't read my notes - Sorry!). The copper coins are essentially a small cutout of copper. Instead of having a whole copper layer internally as a heatsink (which is possible) he uses the coins. Also the coins can go on the outer layers. They are very small, and don't really resemble heatsinks. See the photos. He prefers Rogers Cool Span epoxy to attach the coins to the board as this epoxy can cure in low temperatures or even in a vacuum. This is a conductive epoxy/heatsinking compound. It's possible to put the copper coins on inner layers (this will become more interesting later as we talk about embedding dies inbetween layers of a pcb...). The enig vs. electrolytic gold plating: Enig is typically 2-4 microinches, while elctrolytic can be as high as 50-100 micro inches. The enig can't get too thick or it will corrode a below layer. | |||||

| \subsection{Polar Instruments} | |||||

| Polar instruments makes a calculator type software (see their website) to help improve yield with high speed and inner layers of a PCB. I asked if there was a scripting interface available, but currently you would export from the program to Excel or XML and then act on that data. I'm not entirely sure if scripting is helpful for this software, but I suppose it can't hurt so it was the one question I had from looking at their website. | |||||

| For an idea of what they do, see the Transline section of the PCB Calculator on KiCad and then consider what they software woould look like if this was a full fledged program. Obviously there is a lot of potential for improvement in Kicad, which really just introduces you to the concept. | |||||

| From my research beforehand, the need for software like this is to take high speed signals, and put them in a type of coaxial like trace on the circuit board. There are different ways to do this, but you could, like coax, put a dielectric layer, then a conductive ground around the signal, just in pcb form. The PCB is a component. Impedance is usually 40-120ohms (think 50 or 75ohms for radio or tv). Higher impedance is tougher to handle as the traces get smaller. Typically, 28,50,75, or 100 ohms.Differential wires \gt coaxial type wires. | |||||

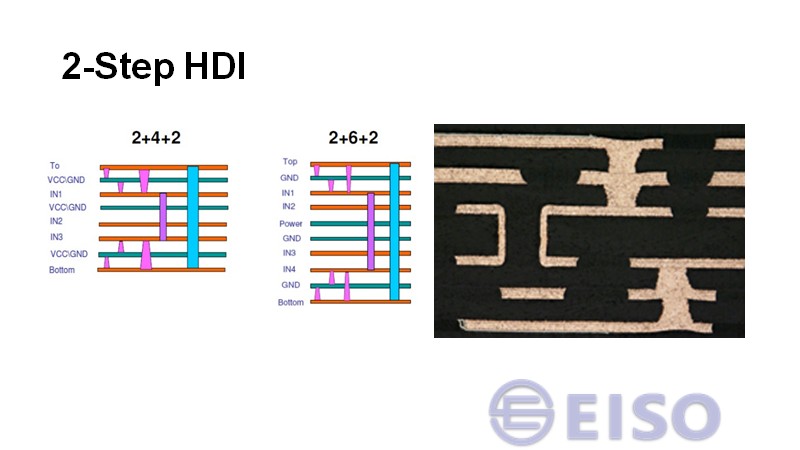

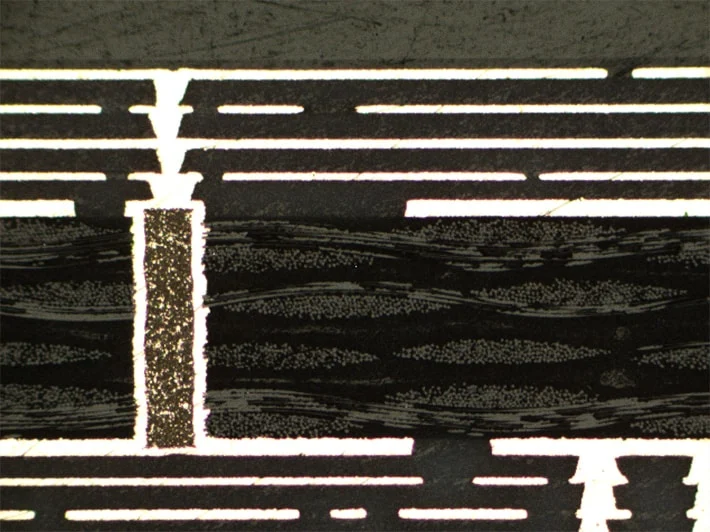

| You should also be aware that when pcb is etched in a subtractive process (pre-Ultra HDI) that the traces get a type of upside down pyramidal shape when cut in a profile or cross section. This is because the etchant attacks the bottom part of the trace slightly more (gravity?) This has effects on the signal as well. There is a good photo, and I'll include it in the git repo for this article (2023 git) where you can clearly see that pcb traces are not square when etched. I'd imagine milling pcbs would be different. | |||||

| \subsection{Facet LLC} | |||||

| An overseas fab who also does plastic injection molding design work. They ship out the injection to manufacturers in Asia, but have designers on staff. There is no website for the injection molding yet, but the description on PCBEast did have it listd. One thing that was mentioned to be aware of with Injection molds, was that the molds have a maintenance fee. Over time, the molds will wear out, so this cost is usually included as you go along. However, if you don't use the molds for say, a number of years, and then contact the manufacturers again, they will charge you a maintenance fee to restart the mold. I'm just guessing here, but I'd imagine that they don't keep the molds in inventory, so after a number of years they probably have to make it again. In any case, don't be surprised if there is a maintenance fee. | |||||

| \subsection{Acdi} | |||||

| A fab house from MD. Also do prototyping. His company has a couple locations, including one in Branford, CT. I asked him whether they had different capabilities at the Brandford location vs. MD but he said that his company keeps all equipment standardized across the different locations. He also mentioned that this is not typical, though I asked one other company which happened to also standardize, so I guess it can go either way. | |||||

| One strength: they use Silicon Expert sourcing software, which can give information parts such as obsolecence notices. | |||||

| \subsection{Actnano} | |||||

| This company is a conformal coating company. Their largest customer is automotive. Consumer and solar are also customers. Their company is based around non-pfa coatings. The founder was a Philips employee who saw the toxicity of pfa conformal coatings in electronics, and thus started the business. They has a research office in Cambridge, and manufacture in Wisconsin and the greater Boston area. If you are a consumer who is interested in the coating, you CAN buy it direct from them. | |||||

| The two main coatings they have are either silicone or not silicone based. The automotive industry is worried about migration of silicone, so they don't use that. Though, other industries use the silicone based coating. | |||||

| \subsection{NCAB Group} | |||||

| A PCB fab in NH. He recommended the Pick and Place podcast from Deerfield, MA. He was giving out a PCB Design Guidelines book, though I have too many books at the moment. We talked a bit about the Ultra HDI additive process. As mentioned above typical (down to 3 mill) pcb etching is a subtractive process, but it leaves you with the bowed or upside down pyramid looking traces, and this doesn't work for smaller geometries (such as the 25,50,75,100 micron that ultra HDI is able to do). The ultra HDI process is additive, and there are different ways to do it. Such as MSAP, ASAP, or SAP. I will come back to this more shortly. The actual process to use hasn't been standardized yet, and he mentioned that some fabs were reluctant to start it (while someone later mentioned that the process actually was easy - there was some disagreement on this point). | |||||

| \subsection{Quantic Ohmega & Evans} | |||||

| Quantic is a large parent company, that has gobbled up a number of smaller companies. Ohmega and Evans were the two demonstrating here, but there were a couple others they had fliers for. Ohmega is a producer of copper foil for PCBs, while Evans is a high reliability capacitor manufacturer. Since copper foils is really just for fabs, let's talk about the capacitors. | |||||

| The evans capactitors are high reliability (from apache helicopters to satellites) hermetically sealed type of tantalum capactitor (some side band hybrid tantalum, not standard yellow caps). For example, the Hawkeye radar plane has 700 of these capacitors in it's goofy looking circular antenna that sits above the plane. | |||||

| How do they test these for space? There is a standard by Nasa, INS002, which is a rigorous (and expensive) test for space devices. There is a screening section of the test, followed by a qualification section. I'm not going to research the test now, but you can look it up online. These days a lot more companies are been going to space and they have to cut costs a bit, so instead of doing the whole INS002 test, this tech recommends choosing specific tests that apply to your product. He had actually just done a webinar on this, coincidentally. So, if you are concerned about vibration, then do that test. And so on. | |||||

| For testing MTBF, they will look at field data. They will also put components, powered on, in an oven pre-heated to 85 degrees celcius, and leave them for 2000 hours, checking them at every 500 hours. Afterwards they will check the specs to make sure nothing has gone terribly wrong. | |||||

| With the highest end customers, what they will do is take for example, 40 capacitors, run the INS002 test, then take only ten out of those 40 for actual use. For the photos, you can see some of the capacitors they sell. One of them he mentioned costs around $500! And they sell round or rounded rectangle caps. The rounded rectangle as simply to get a little more capacitance in the same board size. Finally, there is an open cap so you can see how they are built, and a gold or brass coloured box that is just a collection of six of the caps. Look at the photos. These capacitors are all hand assembled. | |||||

| \subsection{Trilogy-Net} | |||||

| A fab. They had an interesting EMI/EMC compliance test that he would run for \$500, or even free for their pcb customers. Using EM Viewer software, and a custom board built of a number of RF Antennas (see photos), they would place the pcb on top of this RF board, and look for any spurious signals on a spectrum analyzer. | |||||

| So if you want to do some precompliance testing, you can make a custom board like his. I was able to get a video of the chips | |||||

| they used for the board, and he didn't mind, so maybe I'll consider making a similar board. I have a feeling that EMI/EMC compliance testing might be something I'd enjoy. Find a niche that you can dive into. This is one that doesn't take a lifetime, and is practical. | |||||

| \subsection{Metallic Resources} | |||||

| A solder company from Ohio. They sell direct. They are not on Digikey. They sell a number of solder products, flux, bar, paste, etc... They specialize in recycling lead and silver solder. They sell to consumers, I believe. | |||||

| \subsection{American Standard Circuits} | |||||

| A fab from Illinois. An old timer, had been in the business since 1978, He had a bit to say about ultra HDI. The ASAP process for ultra HDI (high density interconnects) can get down to 25 microns, maybe even lower. While the MSAP process can only go down to 30 microns. Given the track layers are so thin, at 25 microns, it's possible for him to take the place of substrates that would usually be on silicon. I was thinking like SOC, like the pocket beagle but i'm not sure that is what he had in mind. He mentioned it would be feasible to put a die inside the layers of the pcb, and then route it out via the 25 micron traces. That is a bit fascinating, and slightly horrific for security folk. ICs embedded in the layers of the pcb. I guess you would have to do xray analysis to see them. One benefit of the ultra HDI as well, means smaller boards. So instead of a 20 layer board, you could get it down to 4. That is a cost savings that justifies the ultra HDI. This is contrary to what NCAB group said. He also mentioned that it's possible to mix ultra HDI with standard 3 mil etching, if for some reason you wanted to do this, and it's not necessarily more expensive. Although you lose the size reduction if you go to 3 mil traces of course. | |||||

| His capability was as low as 12.5 microns reportedly. He showed me a business card sized pcb with 25, 50, 75, and 100 micron traces on it. There is a photo in the git repo. A louvre was necessary to see the 25 mil traces. The 100 mil traces are visible through the naked eye, and also through the photo. | |||||

| SAP stands for semi-additive process (ASAP,MSAP,SAP above). For copper trace peel strength, I think he mentioned that standard numbers are around 4lbs. / inch for FR4. Teflon is much higher, and flex can also get quite high, perhaps 25 lbs. / inch. I forget if there was some connection between the ultra HDI and the peel strength (may have been). | |||||

| One simple difference between traditional 3 mil etching pcbs (subtractive) and the additive process (ultra HDI) is this simple fact: Traditional etching starts out with the copper foil layer and then subtracts, while the additive process has a plating part to it. The copper isn't traced from foil, but from a chemical reaction. | |||||

| \subsection{Fischer Technology} | |||||

| This is a tool maker, they have a couple of products for measuring surface coating thickness. They sell to pcb fabs, but also to other industries. Their website has some of their products, but for example the Sigmascope measures resistivity on non-ferrite metals such as aluminum and copper. It is a handheld device and has a non conductive polymer tip which is placed on the metal. By inducing eddy currents in the metal, they detect the resistivity. | |||||

| For ferrite metals, there is a separate type of handheld tool. This one works on magnetic induction. It's used for solder joints, and welding (possibly some other applications, I forget now). | |||||

| They also had a box type appliance, where you place a pcb in, and via x ray fluorescence, it will give you the surface coating layer of gold. This is used for enig finishes, where the fabs prefer it to be on the lower end of 2-4 micro inches(might have the wrong measure). They are a manufacturer of these devices. | |||||

| \subsection{Hz0} | |||||

| A conformal coating house. Take a look at the photos. Their coatings are non conductive while applying, so you can literally drop a running rpi into the vat of resin and it will keep operating. | |||||

| This particular conformal coating company does not sell its resin. You must ship them your boards and they will apply the coatings. It's possible to solder through the coating, but rework is still relatively difficult. Unfortunately, there were no 'jello-like' conformal coatings vendors at this expo. I asked, if I was to have a board with a daughter board or a shield, how would I go about using the coating: would I apply the coating with the two boards attached? But he said, 'no' you mask off the areas you don't want the coating to be applied to and then coat boat, then attach them. | |||||

| He mentioned the coating was quite thin. For the rework, I wonder if there is a solution where you can reverse the coating with an appropriate solvent. | |||||

| \subsection{JBC} | |||||

| You should know already, that JBC is a manufacturer of soldering irons. I took some pictures of two things I found interesting. They sell a nice spring loaded and adjustable pcb holder model number: PHS-SA (see photos in git). below that was a separate heater. It turns on extremely quickly. It's some kind of heat below glass, yet the heat quickly radiates up. A fun piece of equipment. That with the pcb holder was the most interesting. They also had a very fine tipped hot air gun, at a thickness of some 2mm or so. Really small for hot air. It's easily confused with a soldering iron. | |||||

| \subsection{xDry} | |||||

| Another Texan. Why is it that I can often tell a texan at expos. This is not the first time I've met one at such, and the accent always gives them away (though to be fair, there was another texan at this expo which did not have an accent). Jokes aside, xDry sells drying storage cabinets. There are different sized models. They work via dessicant. They are not temperature controlled, though they have the option for nitrogen to be put in them for an inert atmosphere. The nitrogen also helps, for the recovery time, for if you open the door to take out a device inside, the ambient (moist) air will rush in. The nitrogen is used to quickly bring it back down to a dry atmosphere. | |||||

| Since my family company has or is actually getting nitrogen on site (and it's not an unreasonable expense from what I understand) this is not a bad addition to the drying cabinets. For the temperature controlled drying areas, he mentioned that there is another company, Thermotron, to look at for those. | |||||

| \subsection{Downstream Technologies} | |||||

| This is a software company. Their main software is CAM350 (office365?), although they have another one named Blueprint which is up and coming. The rep mentioned that their software was likely used to make some modern cellphones. I haven't heard of this, so will have to investigate. Cam350 is how I feel when my surveillance cameras don't work. (They see all but 10 degrees...? The 10 degrees you need...) | |||||

| CAM350 reads ODB files which are a common output format. These are not to be confused with Libreoffice' ODB files. There is some discussion of ODB on the kicad forums: https://forum.kicad.info Apparently there is some contention between Gerber, ODB, and IPC-2581 to become the defacto standard for output and assembly from CAD software. | |||||

| \subsection{G.S. Swiss} | |||||

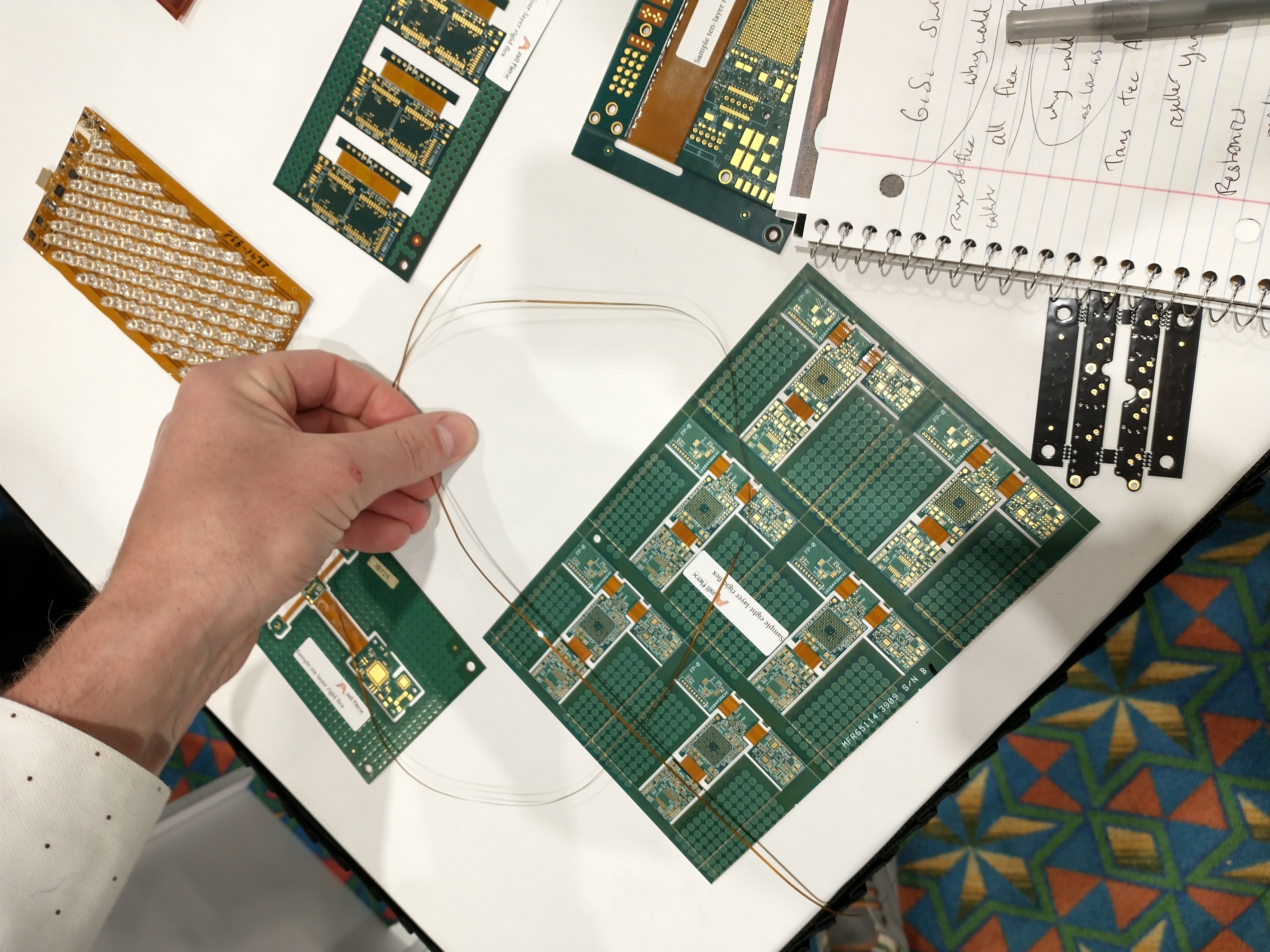

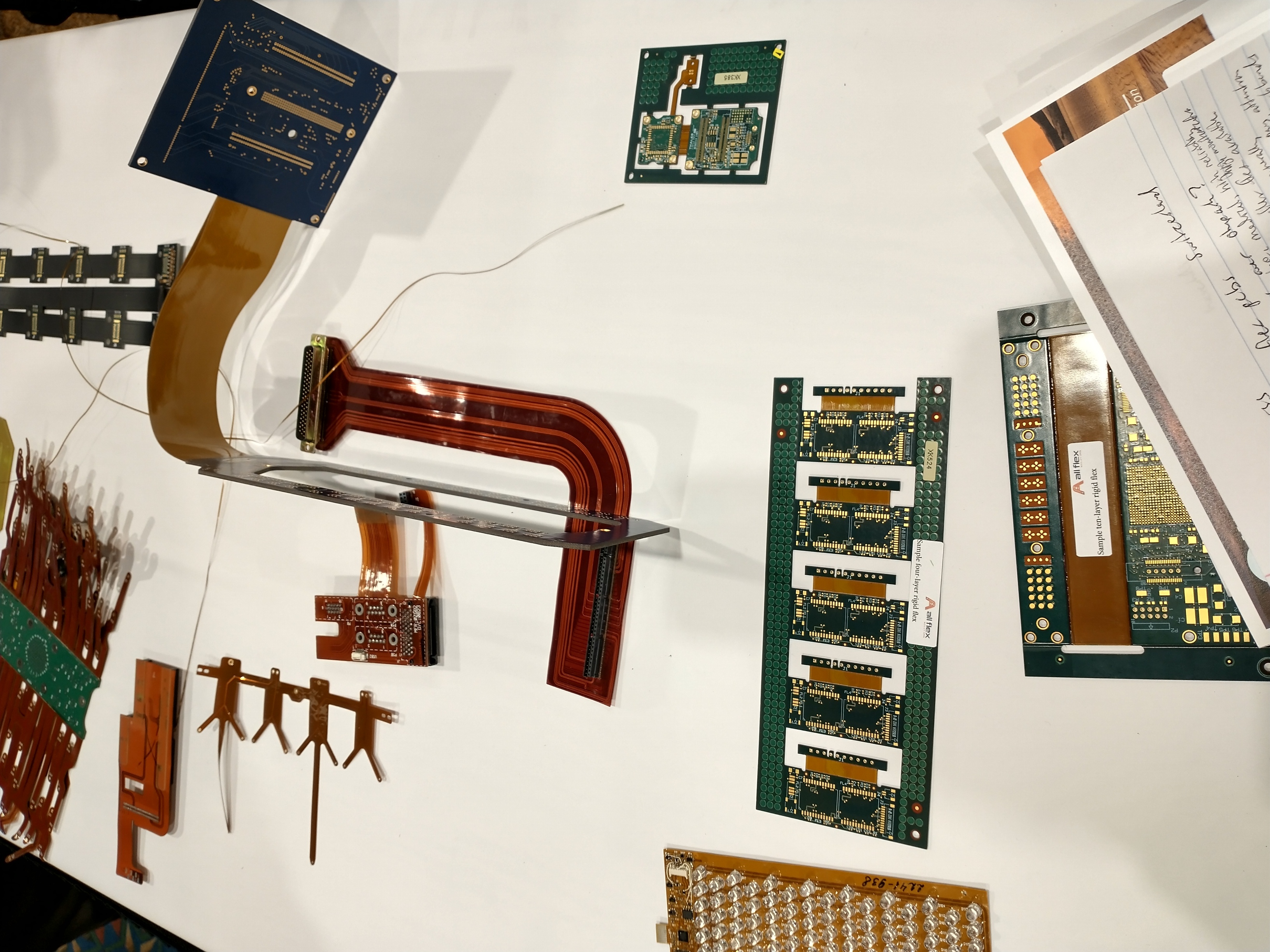

| A flex PCB manufacturer. While you can always purchase flex PCBs from oshpark, you only get one type. There are specialists flex PCB makers, which are able to do more. His business he mentioned is a niche business, for high reliability applications. Typically his pcbs are not repeatedly flexed, i.e. in a active moving fashion. You would flex them once for assembly. He said it's important to pay attention to the number of bends with flex pcbs for reliability. So any moving applications might not work with flex. His pcbs can get as thin as 12 microns, similar to a plastic bag or tissue paper (not kleenex, but the coloured tissue paper). Much thinner than what you will see at, e.g. Oshpark. | |||||

| I asked him what some issues are that he's seen over time. He mentioned one customer used an autoclave to clean a medical device which had a flex board inside, and this caused issue, so repeated heat and or low pressure. Bonding to PCBs can also be problematic. | |||||

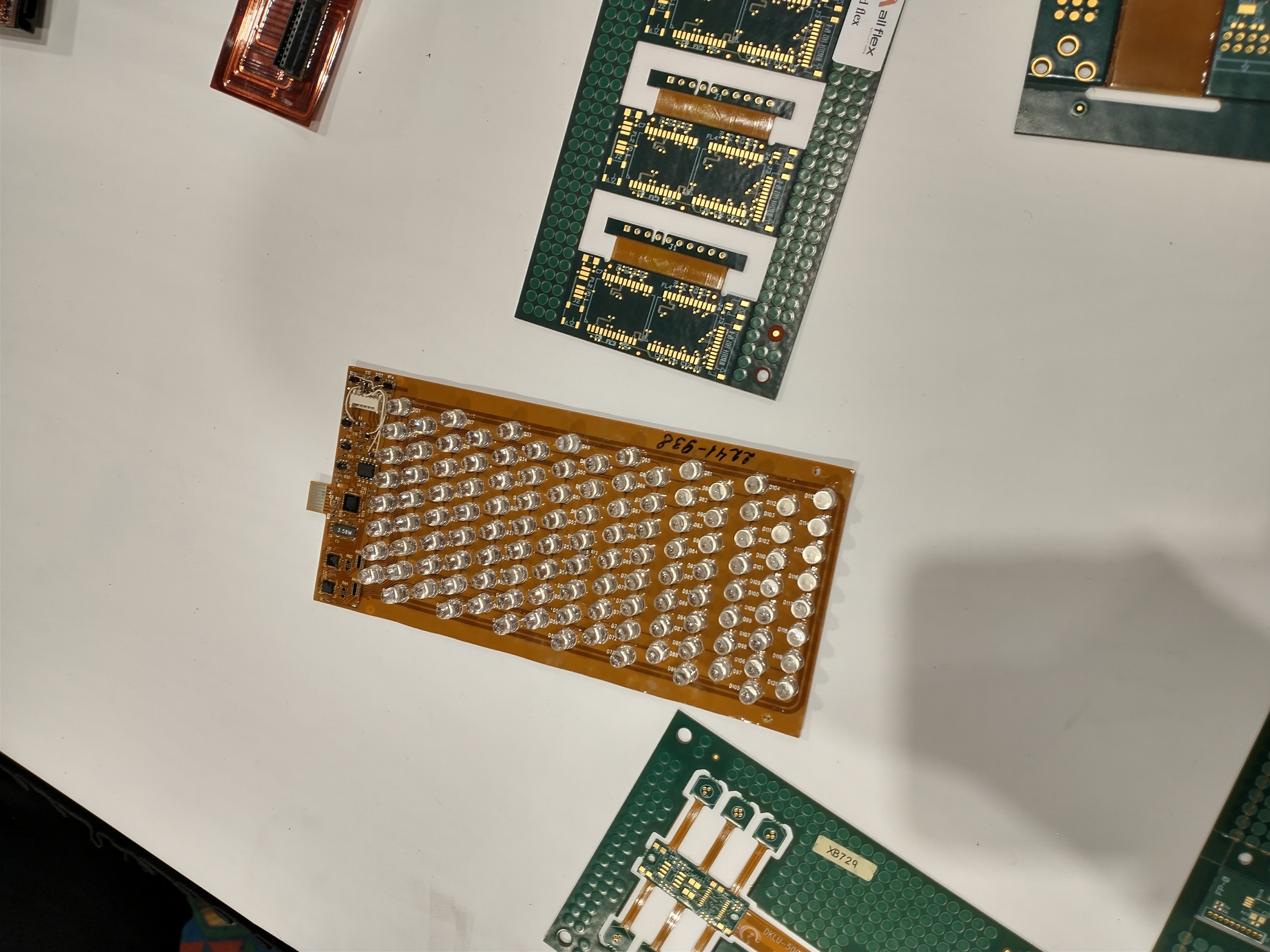

| \subsection{All Flex Solutions} | |||||

| Another flex board manufacturer. Now, this company had an interesting flex board which I took a picture of. It's the photo that looks like someone is holding a piece of string. That string or wire looking piece of flex actually has 4 or 5 tracks on it. I think he mentioned that it was used in a catheter. And it's quite long. One of this companies strengths is the ability to make longer pieces of flex. They also are the company with the LED array on the flex. | |||||

| He mentioned getting to 2 microns size (if I remember right...). | |||||

| \subsection{Lightspeed MFG} | |||||

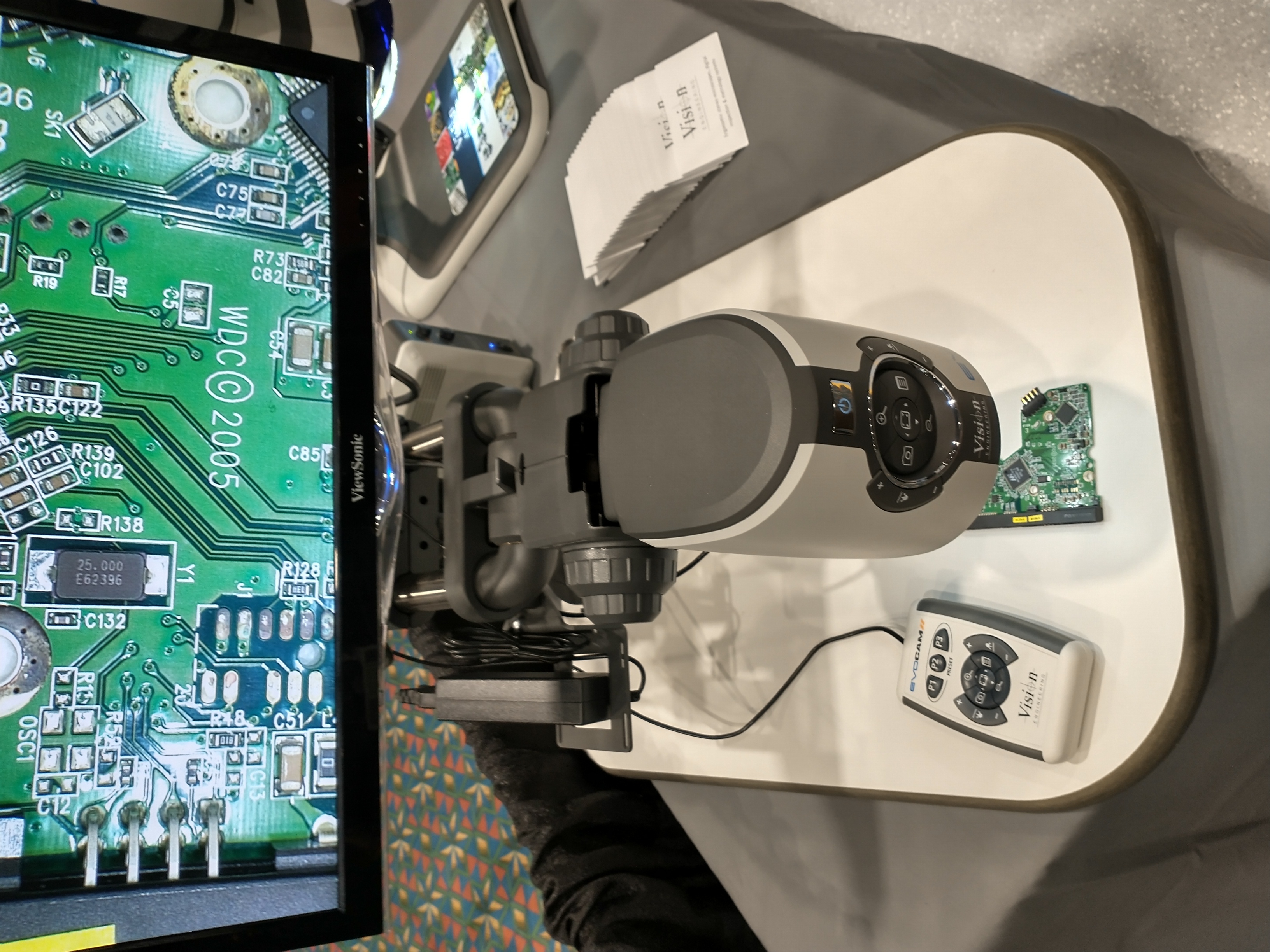

| This is an assembly house (possibly a fab) in Haverhill. He had an interesting type of rubber ball with cameras on it (see photos). This device could be used by e.g. police. He mentioned that they might use this, as an alternative to SWAT. As it would be too difficult to wait for SWAT to arrive, so they could use the camera ball in a given situation. | |||||

| He has worked with a couple of charity type groups in the area, such as iHub/innovation hub at uMass Lowell/Haverhill. That is a lab type makerspace for Umass. Two locations. Billed as a coworking space, it has 'light tools' a 3d printer, and some electronics equipment in at least one of them. I asked if I could tour his business since he's local and he accepted, though I don't know if I have a need to visit a fab / asm house at the moment. The option is there, at least. | |||||

| \subsection{Imagineering} | |||||

| A fab house. One quick thing I didn't realize. This company, like a lot of the board houses, had a stack of PCBs on the table. The aluminum boards, which are just single sided traces on a relatively thick piece of aluminum - these can be used not just for LEDs (power dissipation ofc), but also for corrosion resistance. I hadn't considered that use case before. | |||||

| \subsection{Akrometrix} | |||||

| Has some ovens to test thermal warping, and strain metrology. The devices go as low as -50 celcius and I asked him how they manage that. The answer was liquid nitrogen. | |||||

| \section{Conclusion} | |||||

| And that is it for my notes. Take a look at the photos and videos. I'll try to put everything in the git, and maybe put together a single video for the blog post. | |||||

| A smaller expo, much smaller than Eastec the machining expo in Springfield, but still a good time. The parking was well done, and highway access was easy. I can't complain. I had a good time. Another succesful expo. I swear there is a good living just traveling to expo after expo. There must be a job out there for someone to do market research like that. That is a job worth having. | |||||

| \end{document} | |||||

+ 108

- 0

pcbeast_2023/notes/3.tex~

View File

| @ -0,0 +1,108 @@ | |||||

| \documentclass[11pt]{article} | |||||

| %Gummi|065|=) | |||||

| \usepackage{graphicx} | |||||

| \usepackage{caption} | |||||

| \usepackage{xcolor} | |||||

| \usepackage[vcentering,dvips]{geometry} | |||||

| \geometry{papersize={6in,9in},total={4.5in,6.8in}} | |||||

| \title{\textbf{Door Alarm}} | |||||

| \author{Steak Electronics} | |||||

| \date{} | |||||

| \begin{document} | |||||

| \maketitle | |||||

| %\tableofcontents | |||||

| \textcolor{green!60!blue!70}{ | |||||

| \section{PCBEast 2023}} | |||||

| PCBEast 2023 was a three day conference and 1 day expo in Boxboro, MA. It was located at the Boxboro Regency Hotel, and was about 3 minutes from the intersection of route 2 and route 495. This expo was about 1 medium sized function room, so a smaller expo. There were about 4 aisles of maybe 12 companies each, so about 50 companies. Companies were global, but mostly US, with some from Asia and even less from the EU. The main company here was PCB Fabs, but there were a number of supporting businesses, and visiting an event like this is relevant for anyone who designs a PCB, not just fabs. Any EE might benefit from an event like this. | |||||

| I'm going to write up a bit on expos in my third book, so if you are interested in general expo advice (from someone who is a fan of visiting any type of expo) see that. This article is going to be a writeup of my notes from the expo. I typically write questions beforehand, and then visit each booth asking them my questions, branching off into new ideas as they come. So This list will show what I learned from the vendors I visited. Note that I didn't have time to visit all the vendors, as I procrastinated until the night before to write the questions by accident (haven't been to enough expos lately), so I only visited a selection of vendors. Here we go. | |||||

| \section{Q & A Section} | |||||

| I didn't actually visit the companies in this order as I started in the middle of the map, but I'll just write them down in order of my notes. And this section won't include the questions but will just be a writeup on each vendor. | |||||

| \subsection{Accurate Circuit Engineering} | |||||

| A fab. He mentioned copper coins as heatsinks on his website. Instead of using a traditional heatsink, he is using semi soft copper from Mcmaster Carr or Grainger, milled in a US xxxx Tools mill (can't read my notes - Sorry!). The copper coins are essentially a small cutout of copper. Instead of having a whole copper layer internally as a heatsink (which is possible) he uses the coins. Also the coins can go on the outer layers. They are very small, and don't really resemble heatsinks. See the photos. He prefers Rogers Cool Span epoxy to attach the coins to the board as this epoxy can cure in low temperatures or even in a vacuum. This is a conductive epoxy/heatsinking compound. It's possible to put the copper coins on inner layers (this will become more interesting later as we talk about embedding dies inbetween layers of a pcb...). The enig vs. electrolytic gold plating: Enig is typically 2-4 microinches, while elctrolytic can be as high as 50-100 micro inches. The enig can't get too thick or it will corrode a below layer. | |||||

| \subsection{Polar Instruments} | |||||

| Polar instruments makes a calculator type software (see their website) to help improve yield with high speed and inner layers of a PCB. I asked if there was a scripting interface available, but currently you would export from the program to Excel or XML and then act on that data. I'm not entirely sure if scripting is helpful for this software, but I suppose it can't hurt so it was the one question I had from looking at their website. | |||||

| For an idea of what they do, see the Transline section of the PCB Calculator on KiCad and then consider what they software woould look like if this was a full fledged program. Obviously there is a lot of potential for improvement in Kicad, which really just introduces you to the concept. | |||||

| From my research beforehand, the need for software like this is to take high speed signals, and put them in a type of coaxial like trace on the circuit board. There are different ways to do this, but you could, like coax, put a dielectric layer, then a conductive ground around the signal, just in pcb form. The PCB is a component. Impedance is usually 40-120ohms (think 50 or 75ohms for radio or tv). Higher impedance is tougher to handle as the traces get smaller. Typically, 28,50,75, or 100 ohms.Differential wires \gt coaxial type wires. | |||||

| You should also be aware that when pcb is etched in a subtractive process (pre-Ultra HDI) that the traces get a type of upside down pyramidal shape when cut in a profile or cross section. This is because the etchant attacks the bottom part of the trace slightly more (gravity?) This has effects on the signal as well. There is a good photo, and I'll include it in the git repo for this article (2023 git) where you can clearly see that pcb traces are not square when etched. I'd imagine milling pcbs would be different. | |||||

| \subsection{Facet LLC} | |||||

| An overseas fab who also does plastic injection molding design work. They ship out the injection to manufacturers in Asia, but have designers on staff. There is no website for the injection molding yet, but the description on PCBEast did have it listd. One thing that was mentioned to be aware of with Injection molds, was that the molds have a maintenance fee. Over time, the molds will wear out, so this cost is usually included as you go along. However, if you don't use the molds for say, a number of years, and then contact the manufacturers again, they will charge you a maintenance fee to restart the mold. I'm just guessing here, but I'd imagine that they don't keep the molds in inventory, so after a number of years they probably have to make it again. In any case, don't be surprised if there is a maintenance fee. | |||||

| \subsection{Acdi} | |||||

| A fab house from MD. Also do prototyping. His company has a couple locations, including one in Branford, CT. I asked him whether they had different capabilities at the Brandford location vs. MD but he said that his company keeps all equipment standardized across the different locations. He also mentioned that this is not typical, though I asked one other company which happened to also standardize, so I guess it can go either way. | |||||

| One strength: they use Silicon Expert sourcing software, which can give information parts such as obsolecence notices. | |||||

| \subsection{Actnano} | |||||

| This company is a conformal coating company. Their largest customer is automotive. Consumer and solar are also customers. Their company is based around non-pfa coatings. The founder was a Philips employee who saw the toxicity of pfa conformal coatings in electronics, and thus started the business. They has a research office in Cambridge, and manufacture in Wisconsin and the greater Boston area. If you are a consumer who is interested in the coating, you CAN buy it direct from them. | |||||

| The two main coatings they have are either silicone or not silicone based. The automotive industry is worried about migration of silicone, so they don't use that. Though, other industries use the silicone based coating. | |||||

| \subsection{NCAB Group} | |||||

| A PCB fab in NH. He recommended the Pick and Place podcast from Deerfield, MA. He was giving out a PCB Design Guidelines book, though I have too many books at the moment. We talked a bit about the Ultra HDI additive process. As mentioned above typical (down to 3 mill) pcb etching is a subtractive process, but it leaves you with the bowed or upside down pyramid looking traces, and this doesn't work for smaller geometries (such as the 25,50,75,100 micron that ultra HDI is able to do). The ultra HDI process is additive, and there are different ways to do it. Such as MSAP, ASAP, or SAP. I will come back to this more shortly. The actual process to use hasn't been standardized yet, and he mentioned that some fabs were reluctant to start it (while someone later mentioned that the process actually was easy - there was some disagreement on this point). | |||||

| \subsection{Quantic Ohmega & Evans} | |||||

| Quantic is a large parent company, that has gobbled up a number of smaller companies. Ohmega and Evans were the two demonstrating here, but there were a couple others they had fliers for. Ohmega is a producer of copper foil for PCBs, while Evans is a high reliability capacitor manufacturer. Since copper foils is really just for fabs, let's talk about the capacitors. | |||||

| The evans capactitors are high reliability (from apache helicopters to satellites) hermetically sealed type of tantalum capactitor (some side band hybrid tantalum, not standard yellow caps). For example, the Hawkeye radar plane has 700 of these capacitors in it's goofy looking circular antenna that sits above the plane. | |||||

| How do they test these for space? There is a standard by Nasa, INS002, which is a rigorous (and expensive) test for space devices. There is a screening section of the test, followed by a qualification section. I'm not going to research the test now, but you can look it up online. These days a lot more companies are been going to space and they have to cut costs a bit, so instead of doing the whole INS002 test, this tech recommends choosing specific tests that apply to your product. He had actually just done a webinar on this, coincidentally. So, if you are concerned about vibration, then do that test. And so on. | |||||

| For testing MTBF, they will look at field data. They will also put components, powered on, in an oven pre-heated to 85 degrees celcius, and leave them for 2000 hours, checking them at every 500 hours. Afterwards they will check the specs to make sure nothing has gone terribly wrong. | |||||

| With the highest end customers, what they will do is take for example, 40 capacitors, run the INS002 test, then take only ten out of those 40 for actual use. | |||||

| \subsection{Trilogy-Net} | |||||

| A fab. They had an interesting EMI/EMC compliance test that he would run for \$500, or even free for their pcb customers. Using EM Viewer software, and a custom board built of a number of RF Antennas (see photos), they would place the pcb on top of this RF board, and look for any spurious signals on a spectrum analyzer. | |||||

| So if you want to do some precompliance testing, you can make a custom board like his. I was able to get a video of the chips | |||||

| they used for the board, and he didn't mind, so maybe I'll consider making a similar board. I have a feeling that EMI/EMC compliance testing might be something I'd enjoy. Find a niche that you can dive into. This is one that doesn't take a lifetime, and is practical. | |||||

| \subsection{Metallic Resources} | |||||

| A solder company from Ohio. They sell direct. They are not on Digikey. They sell a number of solder products, flux, bar, paste, etc... They specialize in recycling lead and silver solder. They sell to consumers, I believe. | |||||

| \subsection{American Standard Circuits} | |||||

| A fab from Illinois. An old timer, had been in the business since 1978, He had a bit to say about ultra HDI. The ASAP process for ultra HDI (high density interconnects) can get down to 25 microns, maybe even lower. While the MSAP process can only go down to 30 microns. Given the track layers are so thin, at 25 microns, it's possible for him to take the place of substrates that would usually be on silicon. I was thinking like SOC, like the pocket beagle but i'm not sure that is what he had in mind. He mentioned it would be feasible to put a die inside the layers of the pcb, and then route it out via the 25 micron traces. That is a bit fascinating, and slightly horrific for security folk. ICs embedded in the layers of the pcb. I guess you would have to do xray analysis to see them. One benefit of the ultra HDI as well, means smaller boards. So instead of a 20 layer board, you could get it down to 4. That is a cost savings that justifies the ultra HDI. This is contrary to what NCAB group said. He also mentioned that it's possible to mix ultra HDI with standard 3 mil etching, if for some reason you wanted to do this, and it's not necessarily more expensive. Although you lose the size reduction if you go to 3 mil traces of course. | |||||

| His capability was as low as 12.5 microns reportedly. He showed me a business card sized pcb with 25, 50, 75, and 100 micron traces on it. There is a photo in the git repo. A louvre was necessary to see the 25 mil traces. The 100 mil traces are visible through the naked eye, and also through the photo. | |||||

| SAP stands for semi-additive process (ASAP,MSAP,SAP above). For copper trace peel strength, I think he mentioned that standard numbers are around 4lbs. / inch for FR4. Teflon is much higher, and flex can also get quite high, perhaps 25 lbs. / inch. I forget if there was some connection between the ultra HDI and the peel strength (may have been). | |||||

| One simple difference between traditional 3 mil etching pcbs (subtractive) and the additive process (ultra HDI) is this simple fact: Traditional etching starts out with the copper foil layer and then subtracts, while the additive process has a plating part to it. The copper isn't traced from foil, but from a chemical reaction. | |||||

| \subsection{Fischer Technology} | |||||

| This is a tool maker, they have a couple of products for measuring surface coating thickness. They sell to pcb fabs, but also to other industries. Their website has some of their products, but for example the Sigmascope measures resistivity on non-ferrite metals such as aluminum and copper. It is a handheld device and has a non conductive polymer tip which is placed on the metal. By inducing eddy currents in the metal, they detect the resistivity. | |||||

| For ferrite metals, there is a separate type of handheld tool. This one works on magnetic induction. It's used for solder joints, and welding (possibly some other applications, I forget now). | |||||

| They also had a box type appliance, where you place a pcb in, and via x ray fluorescence, it will give you the surface coating layer of gold. This is used for enig finishes, where the fabs prefer it to be on the lower end of 2-4 micro inches(might have the wrong measure). They are a manufacturer of these devices. | |||||

| \subsection{JBC} | |||||

| You should know already, that JBC is a manufacturer of soldering irons. I took some pictures of two things I found interesting. They sell a nice spring loaded and adjustable pcb holder model number: PHS-SA (see photos in git). below that was a separate heater. It turns on extremely quickly. It's some kind of heat below glass, yet the heat quickly radiates up. A fun piece of equipment. That with the pcb holder was the most interesting. They also had a very fine tipped hot air gun, at a thickness of some 2mm or so. Really small for hot air. It's easily confused with a soldering iron. | |||||

| \subsection{xDry} | |||||

| Another Texan. Why is it that I can often tell a texan at expos. This is not the first time I've met one at such, and the accent always gives them away (though to be fair, there was another texan at this expo which did not have an accent). Jokes aside, xDry sells drying storage cabinets. There are different sized models. They work via dessicant. They are not temperature controlled, though they have the option for nitrogen to be put in them for an inert atmosphere. The nitrogen also helps, for the recovery time, for if you open the door to take out a device inside, the ambient (moist) air will rush in. The nitrogen is used to quickly bring it back down to a dry atmosphere. | |||||

| Since my family company has or is actually getting nitrogen on site (and it's not an unreasonable expense from what I understand) this is not a bad addition to the drying cabinets. For the temperature controlled drying areas, he mentioned that there is another company, Thermotron, to look at for those. | |||||

| \subsection{Downstream Technologies} | |||||

| This is a software company. Their main software is CAM350 (office365?), although they have another one named Blueprint which is up and coming. The rep mentioned that their software was likely used to make some modern cellphones. I haven't heard of this, so will have to investigate. Cam350 is how I feel when my surveillance cameras don't work. (They see all but 10 degrees...? The 10 degrees you need...) | |||||

| CAM350 reads ODB files which are a common output format. These are not to be confused with Libreoffice' ODB files. There is some discussion of ODB on the kicad forums: https://forum.kicad.info Apparently there is some contention between Gerber, ODB, and IPC-2581 to become the defacto standard for output and assembly from CAD software. | |||||

| \end{document} | |||||

+ 144

- 0

pcbeast_2023/notes/4.tex

View File

| @ -0,0 +1,144 @@ | |||||

| \documentclass[11pt]{article} | |||||

| %Gummi|065|=) | |||||

| \usepackage{graphicx} | |||||

| \usepackage{caption} | |||||

| \usepackage{xcolor} | |||||

| \usepackage[vcentering,dvips]{geometry} | |||||

| \geometry{papersize={6in,9in},total={4.5in,6.8in}} | |||||

| \title{\textbf{Door Alarm}} | |||||

| \author{Steak Electronics} | |||||

| \date{} | |||||

| \begin{document} | |||||

| \maketitle | |||||

| %\tableofcontents | |||||

| \textcolor{green!60!blue!70}{ | |||||

| \section{PCBEast 2023}} | |||||

| PCBEast 2023 was a three day conference and 1 day expo in Boxboro, MA. It was located at the Boxboro Regency Hotel, and was about 3 minutes from the intersection of route 2 and route 495. This expo was about 1 medium sized function room, so a smaller expo. There were about 4 aisles of maybe 12 companies each, so about 50 companies. Companies were global, but mostly US, with some from Asia and even less from the EU. The main company here was PCB Fabs, but there were a number of supporting businesses, and visiting an event like this is relevant for anyone who designs a PCB, not just fabs. Any EE might benefit from an event like this. | |||||

| I'm going to write up a bit on expos in my third book, so if you are interested in general expo advice (from someone who is a fan of visiting any type of expo) see that. This article is going to be a writeup of my notes from the expo. I typically write questions beforehand, and then visit each booth asking them my questions, branching off into new ideas as they come. So This list will show what I learned from the vendors I visited. Note that I didn't have time to visit all the vendors, as I procrastinated until the night before to write the questions by accident (haven't been to enough expos lately), so I only visited a selection of vendors. Here we go. | |||||

| \section{Q & A Section} | |||||

| I didn't actually visit the companies in this order as I started in the middle of the map, but I'll just write them down in order of my notes. And this section won't include the questions but will just be a writeup on each vendor. | |||||

| \subsection{Accurate Circuit Engineering} | |||||

| A fab. He mentioned copper coins as heatsinks on his website. Instead of using a traditional heatsink, he is using semi soft copper from Mcmaster Carr or Grainger, milled in a US xxxx Tools mill (can't read my notes - Sorry!). The copper coins are essentially a small cutout of copper. Instead of having a whole copper layer internally as a heatsink (which is possible) he uses the coins. Also the coins can go on the outer layers. They are very small, and don't really resemble heatsinks. See the photos. He prefers Rogers Cool Span epoxy to attach the coins to the board as this epoxy can cure in low temperatures or even in a vacuum. This is a conductive epoxy/heatsinking compound. It's possible to put the copper coins on inner layers (this will become more interesting later as we talk about embedding dies inbetween layers of a pcb...). The enig vs. electrolytic gold plating: Enig is typically 2-4 microinches, while elctrolytic can be as high as 50-100 micro inches. The enig can't get too thick or it will corrode a below layer. | |||||

| \subsection{Polar Instruments} | |||||

| Polar instruments makes a calculator type software (see their website) to help improve yield with high speed and inner layers of a PCB. I asked if there was a scripting interface available, but currently you would export from the program to Excel or XML and then act on that data. I'm not entirely sure if scripting is helpful for this software, but I suppose it can't hurt so it was the one question I had from looking at their website. | |||||

| For an idea of what they do, see the Transline section of the PCB Calculator on KiCad and then consider what they software woould look like if this was a full fledged program. Obviously there is a lot of potential for improvement in Kicad, which really just introduces you to the concept. | |||||

| From my research beforehand, the need for software like this is to take high speed signals, and put them in a type of coaxial like trace on the circuit board. There are different ways to do this, but you could, like coax, put a dielectric layer, then a conductive ground around the signal, just in pcb form. The PCB is a component. Impedance is usually 40-120ohms (think 50 or 75ohms for radio or tv). Higher impedance is tougher to handle as the traces get smaller. Typically, 28,50,75, or 100 ohms.Differential wires \gt coaxial type wires. | |||||

| You should also be aware that when pcb is etched in a subtractive process (pre-Ultra HDI) that the traces get a type of upside down pyramidal shape when cut in a profile or cross section. This is because the etchant attacks the bottom part of the trace slightly more (gravity?) This has effects on the signal as well. There is a good photo, and I'll include it in the git repo for this article (2023 git) where you can clearly see that pcb traces are not square when etched. I'd imagine milling pcbs would be different. | |||||

| \subsection{Facet LLC} | |||||